SCHLAGEL, INC.

SCHLAGEL, INC.

EDI - V5 CONTROL

Page 3

WIRING THE CONTROL

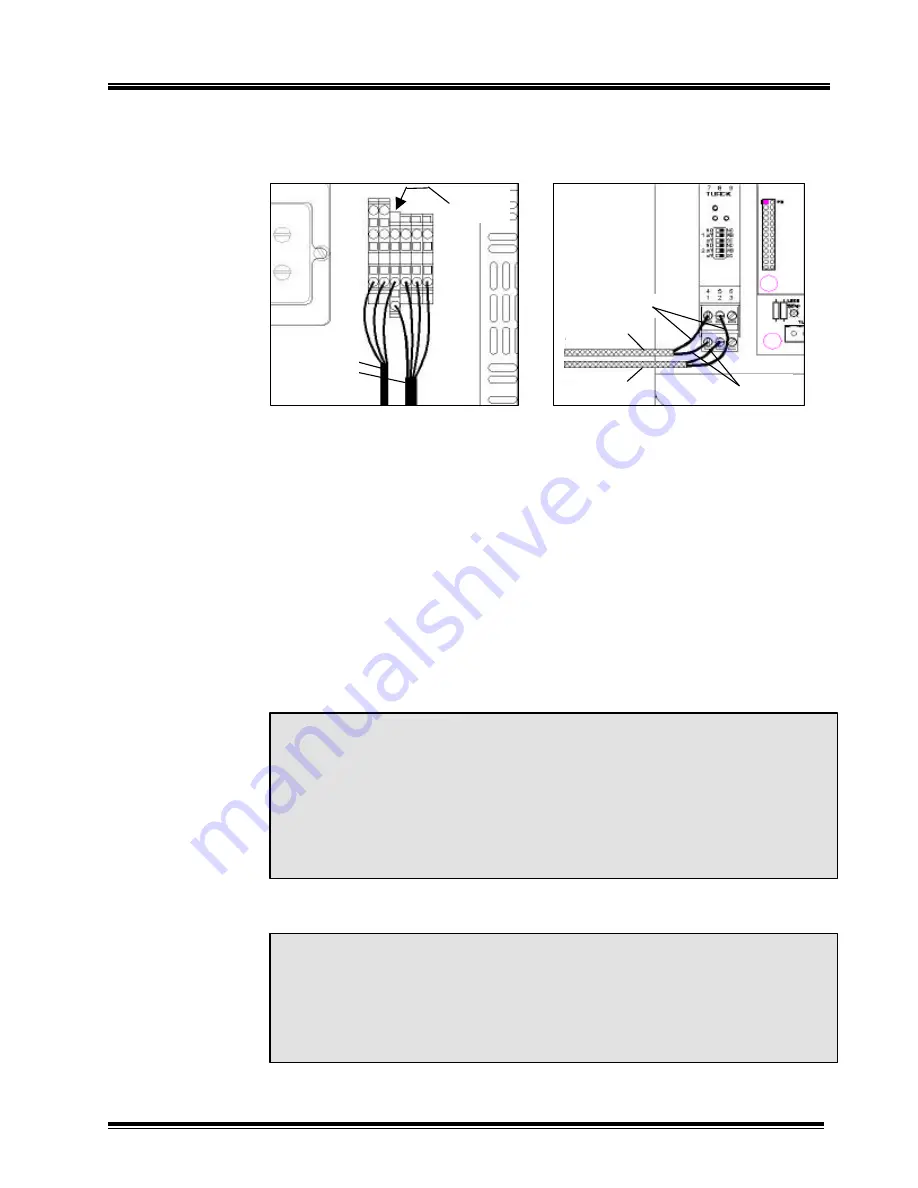

Figure 2

High voltage layout

.

Figure 3

Sensor connections

.

This EDI-V5 control is furnished with an inverter drive, therefore a mechanical

reversing starter is no longer used. Since the inverter can stop the motor in a pre-

determined time, regardless of load, it also eliminates the need for a brake motor.

The installation is further simplified by using a 110 volt supply to power both the

control and the inverter. The inverter converts the this single phase supply to the

220 Volt 3 Phase power needed by the motor.

Caution:

The inverter drive has been factory adjusted to function properly with any

EDI distributor. Changes to these adjustments will alter the positioning of the

distributor spout.

Figure 1 shows the field wiring required for the 110 volt supply, sensor and motor

connections. Wire these using the following 3-step procedure.

Panel Power

110 Volt Wiring

Motor Power

230 Volt Wiring

Step 1 – Supply Voltage

The 110 Volt supply may come from a fused disconnect or a panel mounted

circuit breaker and the connections are made to the 3 terminal block. This supply

should be rated for 10 Amps and is connected at the ‘cage clamp’ terminals on

the control backplane. .

Refer to Figure 2. The hot and neutral wires are connected to either of the gray

colored terminals. Connect the ground wire to the green/yellow terminal.

Step2 – Motor Connections

The 3 phase distributor motor must be wired for 230 volts

.

The motor wires, T1, T2 and T3, are connected to the 3 terminals indicated in

figure 2. The ground wire is attached to the green/yellow terminal. Motor rotation

is not important.

Blue

Brown

Sensor 1

Sensor 2

Ground

Terminal

In 110V 1ph

Out 230V