3

C.

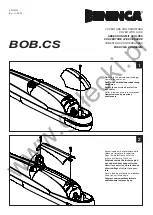

Calculate the correct length to cut the housing extrusion and pushbar extrusion using the door

width as determined in step 1 (dimension “X”).

D.

Calculate the correct length to cut the cover plate extrusion using the door width determined in

step 1.

E.

Cut metal parts to length determined above (using a metal miter saw is recommended to

ensure a good clean cut and a right angle). Do not cut the plastic push pad.

F.

Reassemble the TouchBar (without installing the end caps). Note that the screws which connect

parts to the aluminum extrusions are self tapping (thread forming) screws. It is recommended that

a power tool be used to drive them in. This will make assembly easier.

NOTE: AT THIS TIME THE TOUCHBAR CAN BE HANDED BY ASSEMBLING THE

“PUSH TO EXIT” SIGN (IF FURNISHED) IN THE CORRECT ORIENTATION.

EXTRUSION LENGTH = “X” - 4

13/16

”

COVER PLATE LENGTH = “X” - 20

7/8

”

CHANNEL EXTRUSION

PUSHBAR EXTRUSION

COVER PLATE