6

NovAx™

axial flow fan types ACN-ACW ATEX and ACW EX

amount and interval.

6.7 Dismount of motor

Switch off the power and

disconnect the motor cable in

the terminal box, before

beginning work on the rotor and motor.

The below procedure is with reference to

figure 10 on page 10.

Dismount of motor

1. Dismount any ducts on the inlet and

outlet sides.

2. Remove the centre screw (item 1) and

disc (item 2) that hold the hub cover

and rotor.

3. Remove the hub cover (item 3).

4. Dismount the rotor (item 4) by means

of a puller fastened in the two

threaded holes of the hub boss (item

5).

5. Disconnect the motor cable from the

motor.

6. Support the motor. See table 7 on

page 9 for max. motor weights.

7. Detach the motor from the motor shell

(item 8) by removal of the bolts (item

6) and washers (item 7).

8. Remove the motor (item 11) and

motor flange (item 10).

Do not expose fans and motor

parts to shocks that can result in

imbalance and deformations.

Motor bearings and fan components

are vulnerable parts.

6.8 Mount of motor

Replace lock washers and nuts

during assembly.

The below procedure is with reference to

figure 10 on page 10.

Mount of motor

1. Mount the motor (item 11) and make

sure the motor shaft is centred in the

fan casing.

2. Insert the bolts and washers (items 6

and 7). Tighten the bolts.

3. Mount the rotor (item 4) on the motor

with a tool fastened in the threaded

hole of the motor shaft. The rotor hub

must rest against the motor shaft

collar.

4. Use a feeler gauge to check that the

clearance between the rotor blade tips

and fan casing is the same throughout

the circumference and meets the

below requirements.

• Minimum 2 mm

• 10% of the motor shaft diameter

• Maximum 13 mm

Refer to the motor manufacturer’s

documentation for the shaft diameter.

5. Adjust the motor position with

reference to step 4.

6. Mount the hub cover (item 3), centre

disc (item 2) and centre screw (item 1).

7. Connect the motor cable (item 13) to

the motor (item 11) and the external

power cable in the terminal box (item

12).

8. Reconnect any ducts.

Follow the procedure in section “5. Start

of operation” to start the fan.

6.9 Blade angle adjustment

The rotor blade angles are set in the

factory to deliver the required

performance.

If the fan performance needs to be

changed, it is possible to change the

angles. This requires knowledge of the

motor load and of the max. permissible

blade angle with relation to the motor

rating. If the blade angles are changed,

the rotor has to be re-balanced.

Consult Novenco, before changing the

blade angles. A blade angle tool for angle

adjustment along with instructions for

use is available from Novenco.

7. Troubleshooting

Check for the below faults in case of

breakdowns or lack in performance. Call

for service, if problems persist.

Lack in performance

• Inlets blocked

• Outlets blocked

• Dampers blocked

• Supply air reduced

• Motors defective

• Motors disconnected

• Wrong fan rotation direction

Noises and vibrations

• Motor bearings defective

• Rotors out of balance

• Rotors damaged or worn

• Bolts or components loose

• Wrong pitch angles of rotor blades

Fans that operate in the stall area are

more likely to suffer breakdowns.

8. Inspection and test

It is recommended to test and inspect the

fans at regular intervals with regard to

operability and operation conditions.

Inspect the fans twice a year to ensure

satisfactory function and long life.

Extent of inspection

• Measure power consumption

• Verify torques of fixation bolts

• Cleaning

- inside with pressurised air

- outside with a lint-free cloth with

a mild soapy water solution

• Visual inspection

- Rotors

- Fan casings

- Electric connections

Enter all values and observations in a

log.

9. Sound

The sound emissions depend on the

installation and operation conditions,

hence no general data can be given.

Refer to the fan specifications from the

AirBox calculation program for specific

emissions and to the product catalogue

for more general data.

10. Safety

The installation must be in accordance to

Novenco’s, the current and the local

safety regulations. At a minimum these

include EN 13850.

Use only a manual

grease gun for

lubrication.

Excess grease causes bearings

to overheat and results in

failure.

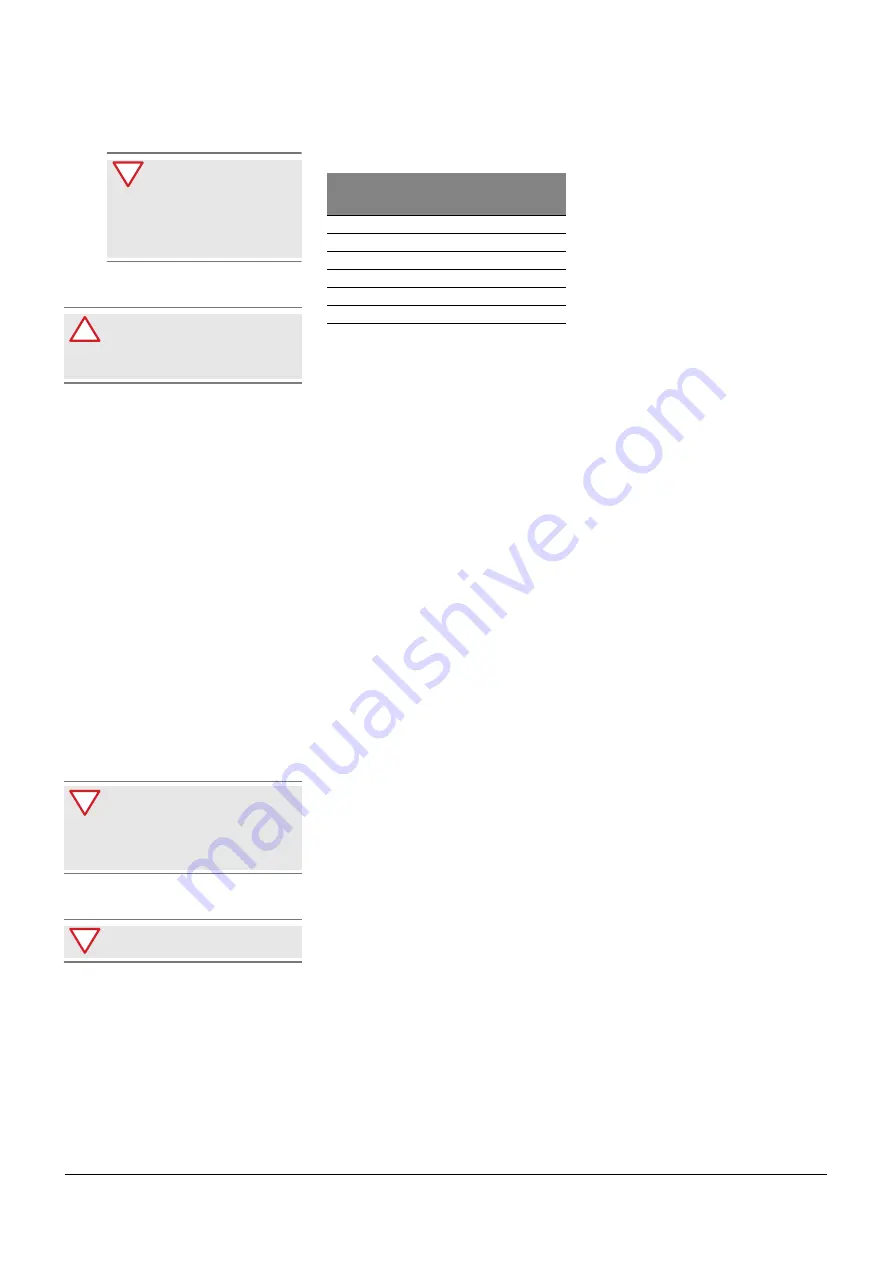

Sizes

Torque [Nm]

Motor bolts (6)

Centre screw (1)

M6

9.4

6

M8

23

12

M10

45

20

M12

78

20

M16

190

25

M20

370

25

Table 4.

Motor fixation torques