Smoke extraction blade damper ERK-MB

TECHNICAL DOCUMENTATION

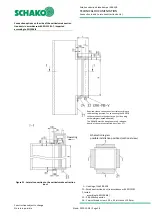

Installation details |

Construction subject to change

No return possible

Stand: 2019-10-08 | Page 12

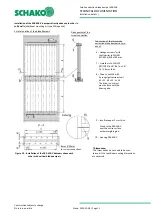

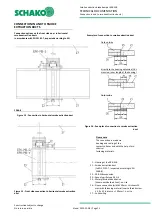

Installation in and on smoke extraction shafts made of

solid building materials

Installation of the ERK-MB-V in and on solid smoke extraction

shafts (made, for example of concrete; masonry accord-

ing to EN 1996 or DIN 1053; solid plaster wall boards

according to EN 12859 or DIN 18163; apparent density ≥

450 kg/m³); wall thickness W ≥ 100 mm.

When installed in smoke extraction shafts, the distance

between them is 0(4) mm and the distance to adjacent

components (wall/solid ceiling) is 75 mm.

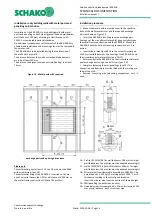

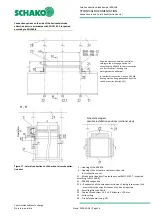

When installed on solid smoke extraction shafts in connection

with mounting brackets (WE-S), the distance between

them is 200 mm and the distance to adjacent compo-

nents (wall/solid ceiling), due to the construction, is at

least 100 mm. Only the horizontal position of the blade

damper axles is possible.

Concrete shaft

Concrete shaft

Figure 11 - Installation on and in solid smoke extraction shafts

Example:

Arrangement on the

concrete shaft

Example:

Arrangement in the

concrete shaft

9 -- Insulfrax paper 5 mm thick.

Glued with waterglass glue on the front.

12 -- Mounting bracket type WE-S (galvanised steel)

23 -- Security grille type ASG-E

30 -- Solid smoke extraction shafts made of solid building mate-

rials (e.g. concrete)

31 -- Seal the circumferential gap of at least 20 mm with mortar

of group II or III, DIN 1053 or with concrete.

Operati

n

g

Operati

n

g