INSTALL THE TREADLES ON THE TREADLE

SUPPORT BAR

Parts: treadle support bar.

Make sure the flat sides of the treadles face up. Remove both

cotter pins and wooden washers from the treadle support bar.

Slide the steel rod out to one side of the three support blocks

(see Figure 2, page 5). It is easiest to install the treadle in its

corresponding slot on the treadle separator beam as you place

the treadles on the treadle support bar.

The support bar accommodates six treadles (including one

treadle installed outside of the support block) on each side of

the center support block. For fewer than 12 treadles, place an

equal number of treadles on either side of the center support

block and use the additional spacers provided to fill any

leftover space.

Working out from the center support block to one side, install

half the treadles included with your loom. Slide a treadle onto

the support bar, and then a 1-1/2" wooden spacer, treadle,

spacer, etc. Then install the remaining treadles on the other

side of the support bar, again working out from the center.

When all treadles and/or spacers have been installed, secure

both ends of the treadle bar with a wood washer and a cotter

pin.

ATTACH THE LOWER LAMM ASSEMBLY

Parts: lower lamm assembly.

Leave the wrapping materials in place until you have attached

the lamms. Make sure the hooks on the lower lamms face

up. From the inside of the left frame side, insert 3/8" x 3-1/2"

hex bolts and 3/8" washers into the two holes for the lower

lamm assembly (see Figure 2, page 5). Insert a barrel nut into

each extension block. Slide the extension blocks over the hex

bolts, turning the barrel nuts if needed. Tighten the hex bolts

securely.

INSTALL THE STEEL BEAMS

Parts: 3 steel beams. The breast and knee beams attach with

truss head bolts; the back beam attaches with hex bolts.

Breast Beam: The breast beam fits into the slots at the top of

the front uprights (see Figure 1, page 4). Thread a 1/2" flat

washer and then a 1/2" fender washer onto each of two 3"

truss head bolts. Insert the bolts into both ends of the beam

and turn the bolts about 1/2" deep into the fittings. Position

the beam with the bolts over the slots in the front uprights,

with the fender washers on the inside and the flat washers on

the outside of the frame. Slide the beam down to the bottom

of the slots. Tighten the bolts by hand, then use the Allen

wrench to secure as tightly as possible.

Back Beam: The back beam fits in the fourth hole from the

top in the rear uprights of the side frames. (Holes closer to the

top accept an optional double back beam and optional tension

box rail.) Attach one end of the back beam at a time. Thread

a 1/2" flat washer onto a 3" hex bolt, then from the outside of

the loom, insert the hex bolt partway into its hole. From inside

the loom, slide a 1/2" fender washer onto the bolt. Raise the

back beam into position and hand tighten the hex bolt into the

beam. Repeat on the other side of the loom.

Knee Beam: The steel knee beam allows for additional leg

room within the loom. Woven material passes over the top of

the knee beam to the cloth beam below. Install the knee beam

in the same way as the back beam, using two 3" truss head

bolts, two 1/2" washers outside of the rear uprights, and two

1/2" fender washers inside of the uprights.

Once the back and knee beams are installed, tighten all beam

bolts with the Allen wrench. Tap all six wedges for the three

wooden cross beams firmly into place again.

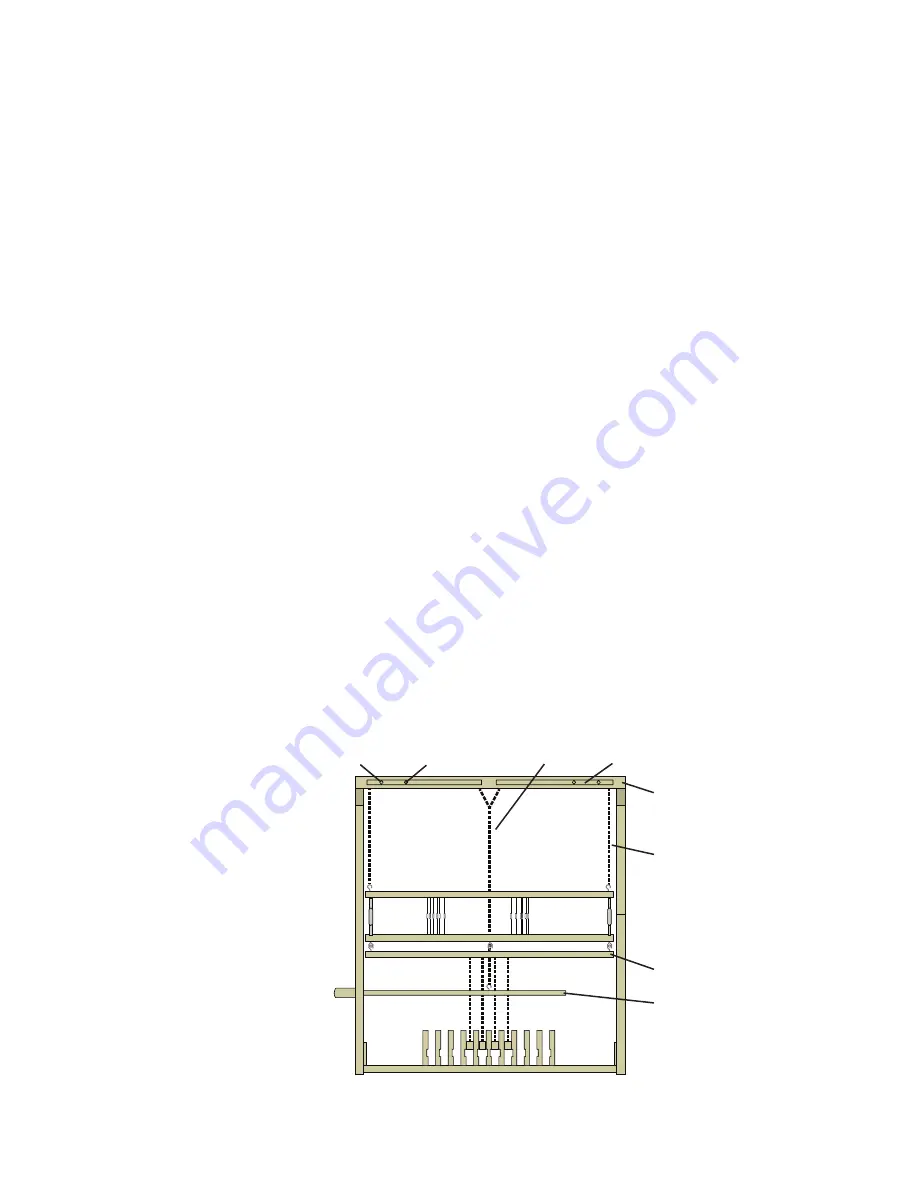

INSTALL THE JACK BOX

Parts: jack box.

Set the jack box on the top of the loom, lining up the pegs in

the bottom of the jack box with the holes on the top of the

frame sides (see Figure 2, page 5). The wooden knobs of the

jack pivots and locking pins should face the front of the loom,

and the cords should hang down (Figure 6). Take care that

the locking pins do not fall out as you maneuver the jack box

into place.

— 8 —

FIGURE 6: JACK AND LAMM ASSEMBLY

— 8 —

lower lamms

upper (suspended) lamms

shaft suspension cord

jack box

jacks (inside jack box)

yoke cord

jack lock

jack pivot