3

■

Features of Twicell Batteries

Extended service life and superior economy

Despite discharge capacity that is virtually equal to that of

conventional dry cells, Sanyo Twicell batteries feature

minimal internal resistance and exhibit excellent discharge

characteristics under high-rate discharge current conditions.

With output power much higher than that of dry cells. Twicell

batteries can withstand over 500 repeated charge / discharge

cycles (conditions stimulated in IEC61951-2(Clause 4.4) , as

well as offering outstanding economy. In addition, even

though the batteries are stored for a long time, the original

capacity is almost recovered by repeated

charging/discharging, offering excellent storage

characteristics.

Wide-ranging lineup and interchangeability with

dry cells

Customized assembled batteries tailored to specific

equipment space requirements are also available.

Excellent high-rate discharge performance and

overcharge/overdischarge capability

Sanyo's original electrode manufacturing process and current

collectors minimize internal resistance, which in turn enables

high-rate discharging and guarantees stable discharge

voltage.

Improved reliability with wide operating

temperature and humidity ranges

In addition to displaying only minimal variation in performance

over a wide temperature range, their totally-sealed

construction gives Twicell batteries high resistance to

humidity. Sanyo Twicell batteries are manufactured under

strict quality control conditions, and undergo 100% inspection

before shipment. This assures superior reliability.

Simple to maintain and strong

The special sealed construction eliminates the need to

replenish the electrolyte, for easier maintenance. As Sanyo

Twicell batteries may be installed in any direction in

equipment, they are exceptionally easy to handle. Moreover,

Twicell batteries employ a rigid metal casing for superior

resistance to shock and vibration.

■

Principle of the Nickel-Metal Hydride

Battery

The nickel-metal hydride battery makes electrochemical use

of the reversibility of the hydrogen absorption/release

reaction in the hydrogen absorbing alloy. The battery uses a

nickel oxide compound for the positive electrode, a hydrogen

absorbing alloy for the negative electrode, and an aqueous

alkaline solution for the electrolyte, which includes such

constituents as potassium hydroxide (KOH). During

charging, the electrolytic reaction of water causes the

hydrogen, which forms in atomic form on the surface of the

hydorgen absorbing alloy in the negative electrode, to

diffuse into and be absorbed by the alloy (charge reaction).

During discharge, the absorbed hydrogen reacts with

hydroxide ions at the surface of the hydrogen absorbing

alloy to once again become water (discharge reaction). In

other words, the active material of the negative electrode

reaction is hydrogen, and the hydrogen absorbing alloy acts

as a storage medium for the active material. Sanyo has

developed a hydrogen absorbing alloy, which absorbs a

large quantity of hydrogen at low pressure and which can

also release it. Sanyo employs this alloy in the Twicell.

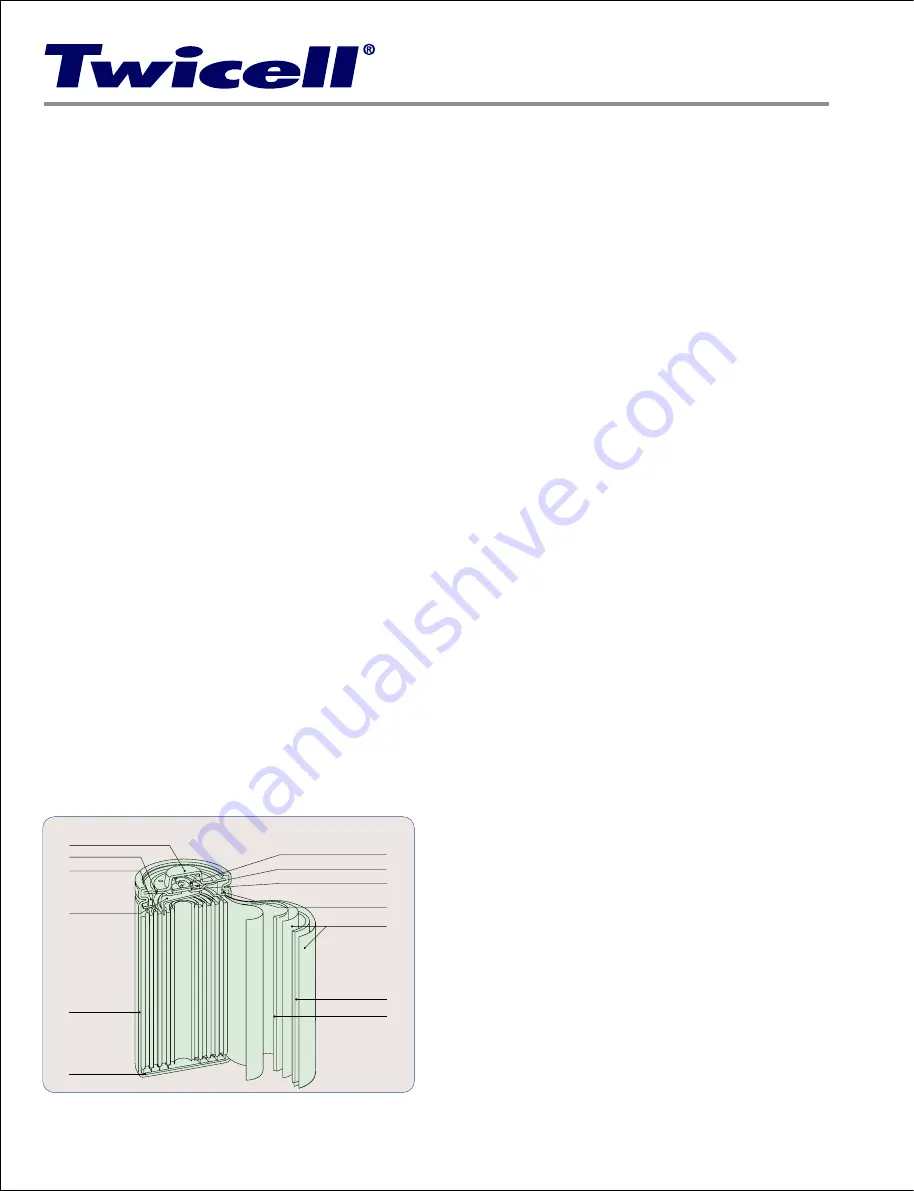

High Cost Performance, Stable Discharge Voltage

Powerful Twicell

Gasket

Negative electrode

Positive electrode

Positive electrode

insulation washer

Negative

current

collector

Positive

current

collector

Casing

(

○

−

negative

terminal)

○

+

Positive terminal

(with built-in gas release vent)

Separator

Cover plate

Seal plate

Rubber plate

Spring

Structural Design