Maintenance

SY50U Excavator OMM

5-56

Operation and Maintenance Manual — 0120

SANY

1. Use the bucket to lift the track on one side. Place an

appropriate supporting device under the frame.

2. Prepare the machine for service. See “Maintenance

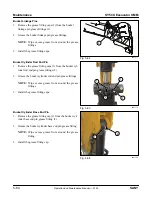

3. Make sure that the grease valve (1) is closed tightly.

4. Using a grease gun, pump grease into the grease fitting

(2) while observing idler movement.

5. Rotate the track one full revolution. Check the track

tension to confirm adjustment.

Decrease the Track Tension

1. Use the bucket to lift the track on one side. Place an appropriate supporting device under the frame.

2. Prepare the machine for service. See “Maintenance Safety” on page

3. Slowly open the grease valve (1) 1 to 1-1/2 turns while observing idler movement. Grease should come out

from behind the grease valve.

NOTE:

If grease does not come out, slowly rotate the track in both directions. When grease begins to flow,

stop and continue the adjustment.

4. When the track sag is within specification, tighten the grease valve to 44

lb-ft–59

lb-ft (60 N•m–80 N•m).

5. Rotate the track one full revolution. Check the track tension to confirm adjustment.

WARNING!

•

The track tension grease fitting is under extreme pressure and grease exiting the valve can

cause serious injury.

•

Do not stand directly in front of the track tension grease fitting valve when loosening the

valve.

•

If track tension does not release after opening the grease valve, never attempt to remove

the track or disassemble any component before pressure is released.

Failure to follow these warnings could result in death or serious injury.

NOTICE!

Remove gravel or mud buildup between the sprocket and the track before reducing track

tension.

Fig. 5-50

0003133

2

1