10 S&C Instruction Sheet 761-545

Installation

S&C Instruction Sheet 761-545

10

Spring-type

washer

Figure 2. Applying the spring washer.

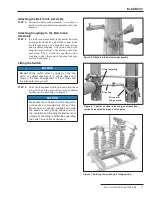

Figure 3. Assembling the pipe coupling to the operating

lever—interphase pipe on both sides of the operating lever.

Operating lever

Pipe coupling

Figure 4. Assembling the pipe coupling to the operating

lever—interphase pipe on one side of the operating lever.

Operating lever

Pipe coupling

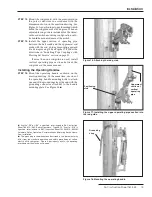

Operating Pipe Preparation

If desired, the operating pipes can be cut to length (if not

precut at the factory) before proceeding to the job site.

Cutting dimensions are shown on the erection drawing.

One of the pipe sections furnished is threaded at one end

to accommodate the operating handle assembly.

Users supplying their own operating pipe should deter-

mine which section of operating pipe is to be the lowest and

thread one end of it for installation of the operating handle.

Provide sufficient thread to allow the pipe to extend

approximately

¼

-inch (6-mm) below the handle coupling.

Mounting to Wood

When mounting the switch and its operating mechanism to

a wood structure or wood pole, S&C recommends suitably

sized square washers be placed under the nuts. S&C also

recommends using spring-type washers between the

square washers and nuts to compensate for wood shrink-

age and thus maintain fastener tightness. See Figure 2.

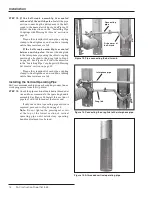

Uncrating the Switch

STEP 1.

Remove the switch poles and bell-crank base(s)

or bracket(s), if applicable, from their crates and

arrange them on the ground in the same order in

which they will be mounted on the structure.

Protect the bearings from contamination by

dirt, mud, oil, etc. If necessary, use blocks to

keep the bearings clear of the ground.

Attaching Couplings to Switch Poles

NOTICE

An adjustable pipe coupling is included for each

interphase pipe section . Typically, these adjustable

couplings are attached to the center switch pole

except for tiered-upright mounting configurations .

STEP 2.

Attach pipe couplings to the operating lever of

each switch pole. Each pipe coupling includes

¼

-inch (6-mm) and

⅜

-inch (10-mm) spacers.

Position the spacers, included with each

coupling, as shown in the section views on

the erection drawing. See Figures 3 and 4.