S&C Instruction Sheet 761-507

23

Installation

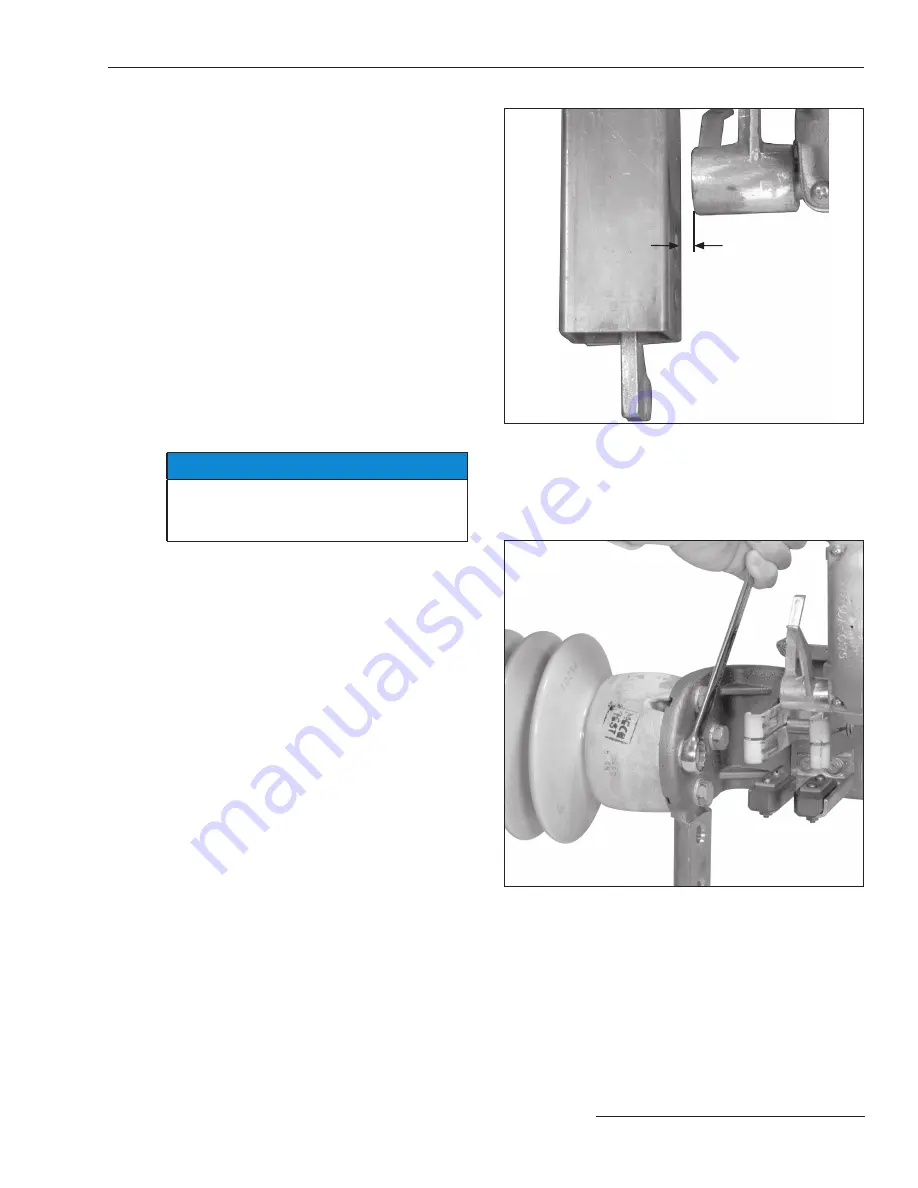

(g) Move the blade assembly slowly toward the

Closed

position until the blade assembly is

under the interrupter lever shaft. Verify the gap

between the end of the interrupter lever shaft

and the blade assembly is between and

3∕16

-

inch

(5 mm) and

9�32

-inch (7 mm). See Figure 36.

(h) If the conditions described above are not met,

adjust as follows. Loosen the four

½

-inch–13

×

1

¼

-inch hex-head galvanized steel cap screws

that fasten the terminal base castings to the

stationary insulators. See Figure 37. Shift the

terminal base castings as required. Tighten the

cap screws and recheck for conformance to the

conditions outlined above. Readjust if required.

Make certain the cap screws are tightened to

fi nal tightness (55 ft.-lb.).

If any of the conditions described in this step

cannot be achieved, contact the nearest S&C

Sales Office because it is likely damage was

sustained during shipment.

NOTICE

Stationary contacts are greaseless and

self-lubricating .

Do not apply lubricant to

the stationary contacts .

Connecting High-Voltage Conductors

When high-voltage conductors are to be connected

using aluminum-alloy body connectors

●

the following

procedures should be used:

(a) Thoroughly wire-brush the current-transfer

surfaces of each connector and immediately

apply a liberal coating of Penetrox® A (available

from Burndy Corporation) to the brushed

surfaces.

(b) Wire-brush each terminal pad of the interrupter

switch and apply a coating of Penetrox A. Then

bolt the connectors to the terminal pads.

(c) Prepare the conductors using established

procedures and clamp them in their respec tive

connectors.

●

(“Mass anode”-type connectors, such as the catalog number 6300

series offered by S&C, that have been designated by the connector

manufacturer as being suitable for direct attachment to copper bearing

alloy terminal pads .

Figure 36. Verifying the gap between the end of the interrupter

lever shaft and the blade assembly.

Figure 37. Adjusting the position of the terminal base casting.

3∕16

-inch (5 mm) min,

9/32

-inch (7 mm) max