17

2-5. You want to check a software program.

•

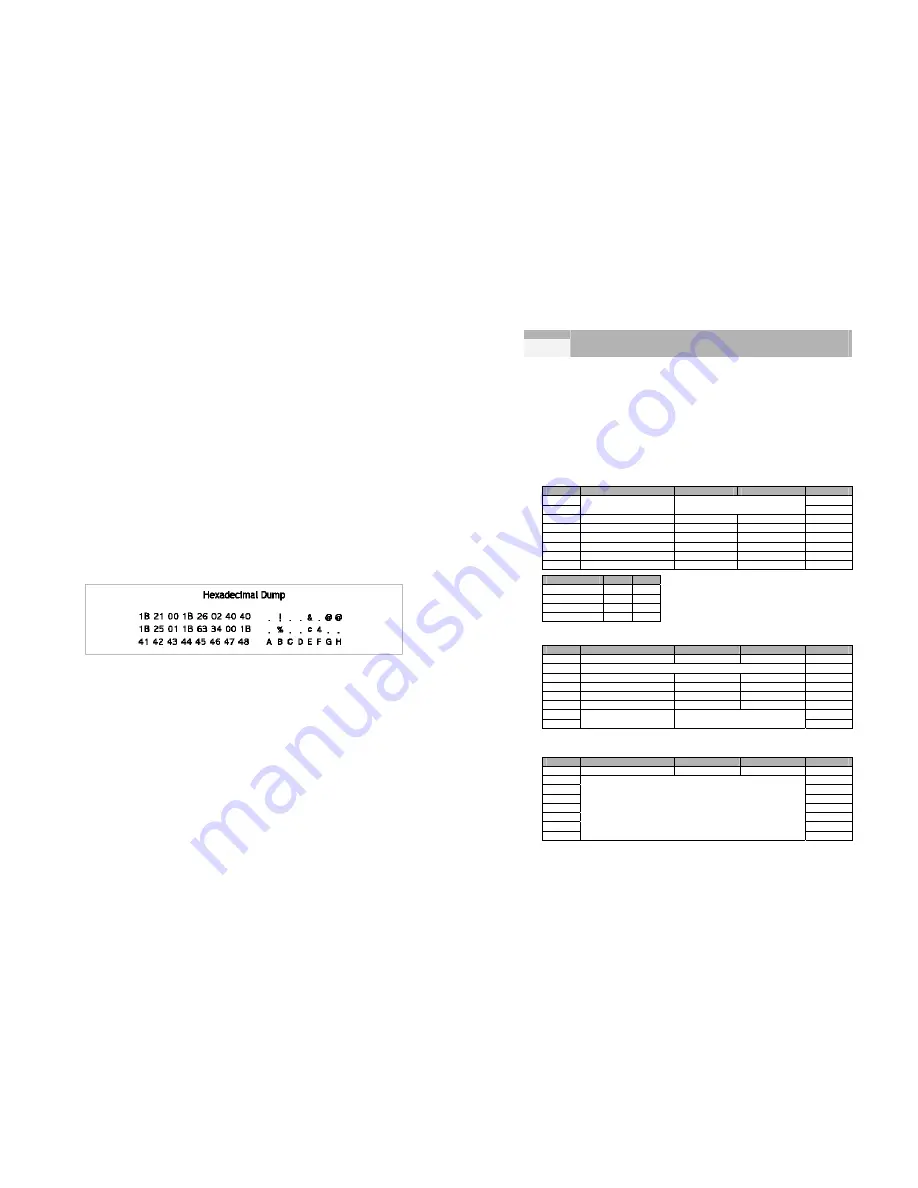

Hexadecimal Dump

This feature allows experienced users to see exactly what data is coming

to the printer. This can be useful in finding software problems. When you

turn on the hexadecimal dump function, the printer prints all commands

and other data in hexadecimal format along with a guide section to help

you find specific commands.

To use the hexadecimal dump feature, follow these steps:

1) After you make sure that the printer is off, open the front cover of the

printer.

2) Hold down the Feed button while you turn on the printer.

3) Close the front cover.

4) Run any software program that sends data to the printer. The printer

prints “Hexadecimal Dump” and then all the codes it receives in a two –

column format. The first column contains the hexadecimal codes and

the second column gives the ASCII characters that correspond to the

codes.

•

A period(.) is printed for each code that has no ASCII equivalent.

5) When the printing finishes, turn off the printer.

18

Chapter 3

DIP switch settings

Although the factory settings are best for almost all users, if you have special

requirements, you can change the DIP switch.

3-1. Setting the DIP switches

•

DIP switch functions

Your printer has two sets of DIP switches.

The functions of the switches are shown in the following table.

DIP - SW1

Switch

Function

ON

OFF

Default

1-1

OFF

1-2

Emulation Selection

Refer to the following table

OFF

1-3 Auto

cutter Enable Disable

OFF

1-4

Cartridge

one cartridge

two cartridges

OFF

1-5 Density

*1)

Bold

Normal

OFF

1-6 Special

Function

*2)

Enable Disable OFF

1-7

Near end sensor

Enable

Disable

OFF

1-8 Low

ink

check Disable Enable OFF

1-1

1-2

EPSON OFF

OFF

STAR OFF

ON

CITIZEN ON

OFF

EPSON-KP

*3)

ON ON

DIP - SW2 (RS232C Serial interface model)

Switch

Function

ON

OFF

Default

2-1

Data receive error

Print “?”

Ignore

OFF

2-2 Reserved OFF

2-3 Hand

Shaking

DTR/DSR XON/XOFF OFF

2-4 Word

length

7bit

8bit OFF

2-5 Parity

check Enable Disable OFF

2-6 Parity

selection

EVEN

ODD OFF

2-7

OFF

2-8

Baud rate selection

Refer to the following table

OFF

DIP - SW2 (Parallel interface model)

Switch

Function

ON

OFF

Default

2-1

Auto Line Feed

Enable

Disable

OFF

2-2

OFF

2-3

OFF

2-4

OFF

2-5

OFF

2-6

OFF

2-7

OFF

2-8

Undefined

OFF

Summary of Contents for Bixolon SRP-500

Page 1: ...Samsung Elector Mechanics Printed In Korea 2003 2 Operator s Manual SRP 500...

Page 16: ...23 Page 3 PC860 Portuguese 24 Page 4 PC 863 Canadian French...

Page 17: ...25 Page 5 PC 865 Nordic 26 page 16 CP1252 WinLatin1...

Page 18: ...27 page 17 PC 866 Russian 28 page 18 CP 852 DosLatin2...

Page 19: ...29 Page 19 PC 858 Euro 30 Page 21 MS DOS 862 Israel...

Page 20: ...31 Page 22 MS DOS 864 Arabic 32 Page 23 MS DOS 874 Thai...

Page 41: ...73 Memo...