EB 8321 EN

8-3

Servicing and conversion

4. Place on diaphragm case (1) and refas-

ten it to the housing (5) with bolts (40),

washers (54) and nuts (50).

8.5

Conversion work

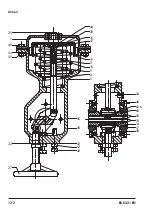

See Fig. 3-1 in the 'Design and principle of

operation' section

8.5.1

Changing the fail-safe

action/reversing the

direction of action

The reversal of the direction of action de-

pends on the valve on which the actuator is

mounted if the valve's direction of rotation or

the fail-safe position of the entire valve as-

sembly is to be changed.

1.

Remove the valve from the actuator hous-

ing and mount it on the opposite flange.

2.

Readjust the stop bolts (42.1 and 42.2)

to limit the opening angle (see 'Adjusting

the stop bolts' in the 'Installation' sec-

tion).

8.5.2

Changing the bench

range

The useable actuator torques depend on the

diaphragm area, maximum signal pressure

and bench range of the actuator.

It is possible to subsequently change the

bench range by removing or adding spring

8, 9 or 10 in the housing (see Table 8-4).

1.

Unthread and remove the nuts (50) and

bolts (50) (including the washers) on the

diaphragm case (1).

2.

Remove the diaphragm case (1) and take

out the diaphragm (20).

3.

Slowly unthread the screw (44) on the di-

aphragm plate (19) to gradually relieve

the spring spring compression.

4. Hold the diaphragm plate (19) stationary

until the screw (44) is completely un-

screwed.

5. Lift the diaphragm plate (19) and center-

ing plate (15) off the springs.

6.

Add or remove the corresponding

springs 8, 9 or 10 (see Table 8-4).

7. Replace the centering plate (15) and dia-

phragm plate (19) on the springs and

fasten them to the actuator stem (2.1)

with screw (44).

8. Insert diaphragm.

9. Place on diaphragm case (1) and fasten

it to the housing (5) with bolts (40),

washers (54) and nuts (50).

10.

Affix a new nameplate with the new

bench range to the actuator.

Table 8-4:

Assignment of actuator springs and bench ranges

Bench range

0.4 to 0.8 0.5 to 1.0 0.8 to 1.6 0.9 to 1.8 1.2 to 2.4

1.3 to 2.6

1.7 to 3.4

Item

(spring num-

ber)

10

(3)

9

(2)

8

(1)

9 and 10

(2 and 3)

8 and 10

(1 and 3)

8 and 9

(1 and 2)

8, 9 and

10

(1, 2 and

3)

Summary of Contents for 3278

Page 10: ...1 6 EB 8321 EN...

Page 12: ...2 2 EB 8321 EN...

Page 18: ...3 6 EB 8321 EN...

Page 22: ...4 4 EB 8321 EN...

Page 26: ...5 4 EB 8321 EN...

Page 28: ...6 2 EB 8321 EN...

Page 30: ...7 2 EB 8321 EN...

Page 36: ...9 2 EB 8321 EN...

Page 38: ...10 2 EB 8321 EN...

Page 40: ...11 2 EB 8321 EN...

Page 42: ...12 2 EB 8321 EN...

Page 46: ...13 4 EB 8321 EN...

Page 47: ......