3

R. 10/19 816 801

SAMOA Industrial, S.A. · Pol. Ind. Porceyo, I-14 · Camino del Fontán, 831 · 33392 - Gijón - Spain · Tel.: +34 985 381 488 · www.samoaindustrial.com

2019_10_22-10:30

EN

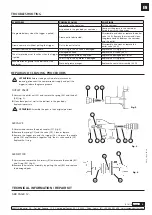

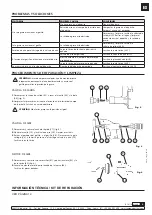

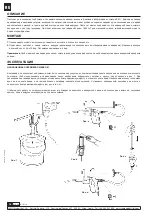

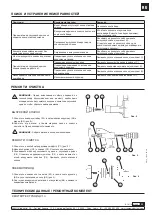

TROUBLESHOOTING

SYMPTOMS

POSSIBLE CAUSES

SOLUTIONS

No grease delivery when the trigger is pulled.

No grease in the container.

Fill the container.

Air pockets in the gun body or container.

Compact the grease in the container.

Purge the air with the purger.

Grease outlet obstructed.

Disassemble and clean or replace the outlet

valve (kit A). Remove the screw and clean

the grease conduit between the container

and the outlet.

Grease comes out without pulling the trigger.

Dirt in the outlet valve.

Disassemble and clean or replace the

outlet valve (kit A).

Air leaks from the air valve needle.

The O ring in the air valve is damaged.

Replace the O ring (kit C).

The air motor does not function when the trigger

is pulled.

Damaged air valve.

Replace the air valve (kit C).

Damaged piston plate or air piston.

Replace the damaged part (kit B).

The O ring in the air motor is damaged.

Replace the O ring (kit B).

Accumulation of grease in the bottom of the

container.

Worn out grease plunger.

Replace the container assembly (kit D).

REPAIR AND CLEANING PROCEDURES

ATTENTION:

Before starting any kind of maintenance or

repairing, disconnect the compressed air supply and pull the

trigger to release the grease pressure.

!

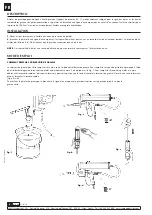

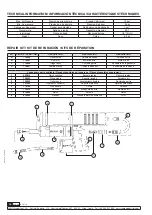

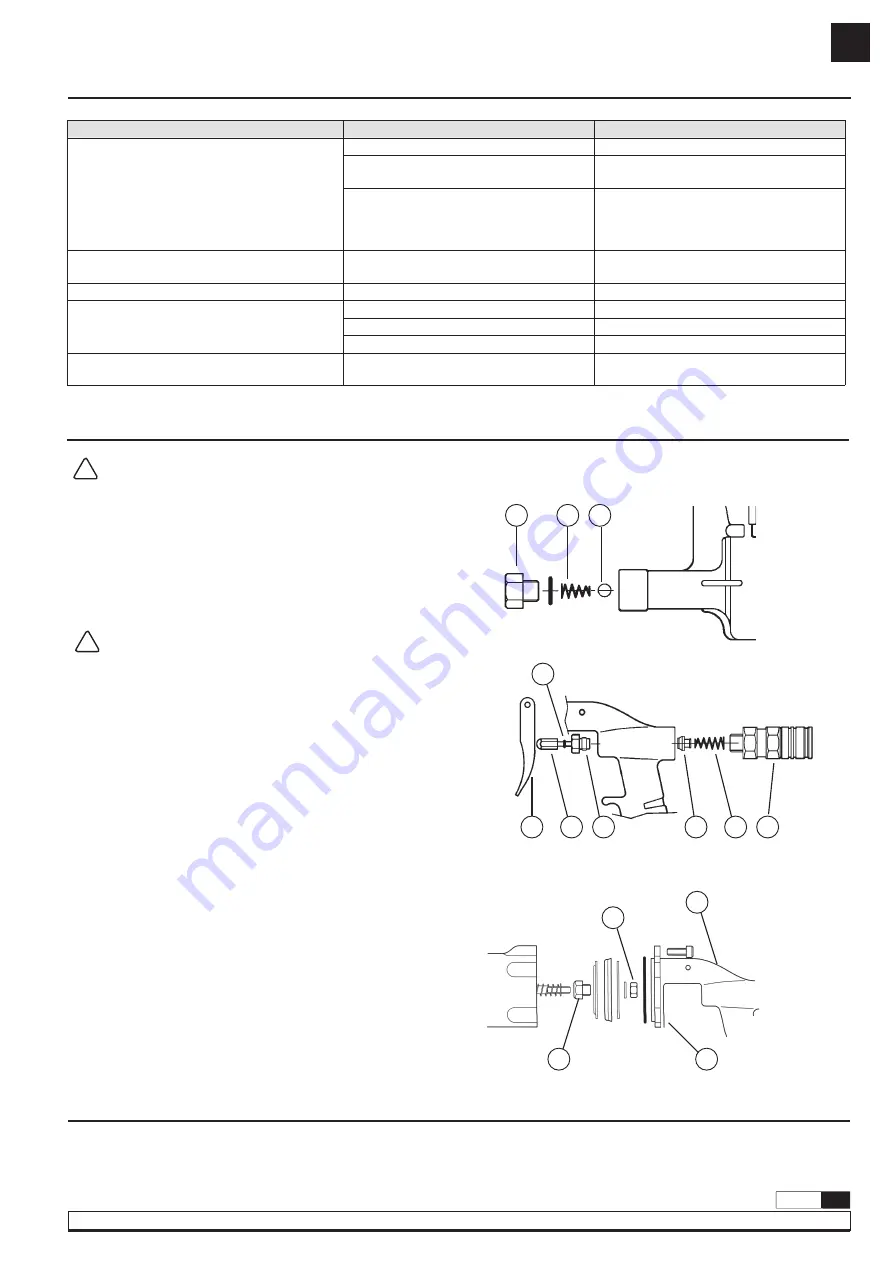

OUTLET VALVE

1.

Unscrew the outlet nut (A1) and remove the spring (A2) and the ball

(A3) (fig. 2).

2.

Clean these parts as well as the ball seat in the gun body.

Replace if necessary.

ATTENTION:

Assemble the parts in their original positions.

!

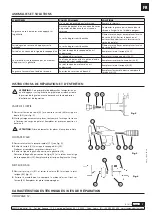

AIR VALVE

1.

Unscrew and remove the quick coupler (C1) (fig. 3).

2.

Remove the spring (C2) and the valve (C3). Clean or replace.

3.

Remove the trigger pin and the trigger (C6). Unscrew the needle

guide (C4) and remove it together with the air valve needle (C5).

Replace the O ring.

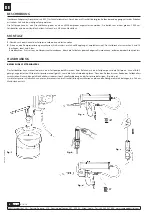

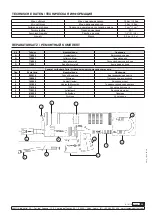

AIR MOTOR

1.

Unscrew and remove the five screws (B1) and remove the handle (B2)

and O ring (B3) (fig. 4).

2.

Remove the air motor assembly by pulling the nut (B4) and replace

the damaged parts.

Fig. 2

A1

A2

A3

Fig. 3

C6

C5

C4

C3

C2

C1

C1

Fig. 4

B4

B1

B3

B4

SEE PAGE 12.

TECHNICAL INFORMATION / REPAIR KIT