Operator’s manual

SCISSOR TRIMMER

PG 150 (F), PG 200 (F)

PG 150L (F), PG 200L (F)

- 17 -

6.2.

After-season maintenance and storing

After the machine has been dismounted from the extension arm, for idle period longer than one

month, perform the following maintenance works:

clean the machine thoroughly from any soiling and then wash and dry,

if need be, perform any repairs, adjustments, replacement of sealing or hoses,

lubricate all lubrication points marked with special label as in

Fig. 6,

remove any sources of corrosion and complement any paintwork defects,

protect non-painted metal surfaces with a thin film of a solid grease, e.g. ŁT – 43, or gearbox,

mineral or motor oil, e.g. 15W40,

complement or replace illegible warning and information labels,

close connection nozzles of hydraulic hoses,

install the guard on the trimmer's cutting bars.

The machine should be stored in a standstill position in a dry and clean place, inaccessible to

unauthorised personnel and animals, on an even and paved ground under a roof or any other cover

protecting it from the weather.

6.3.

Restarting the machine after repairs or longer storing periods

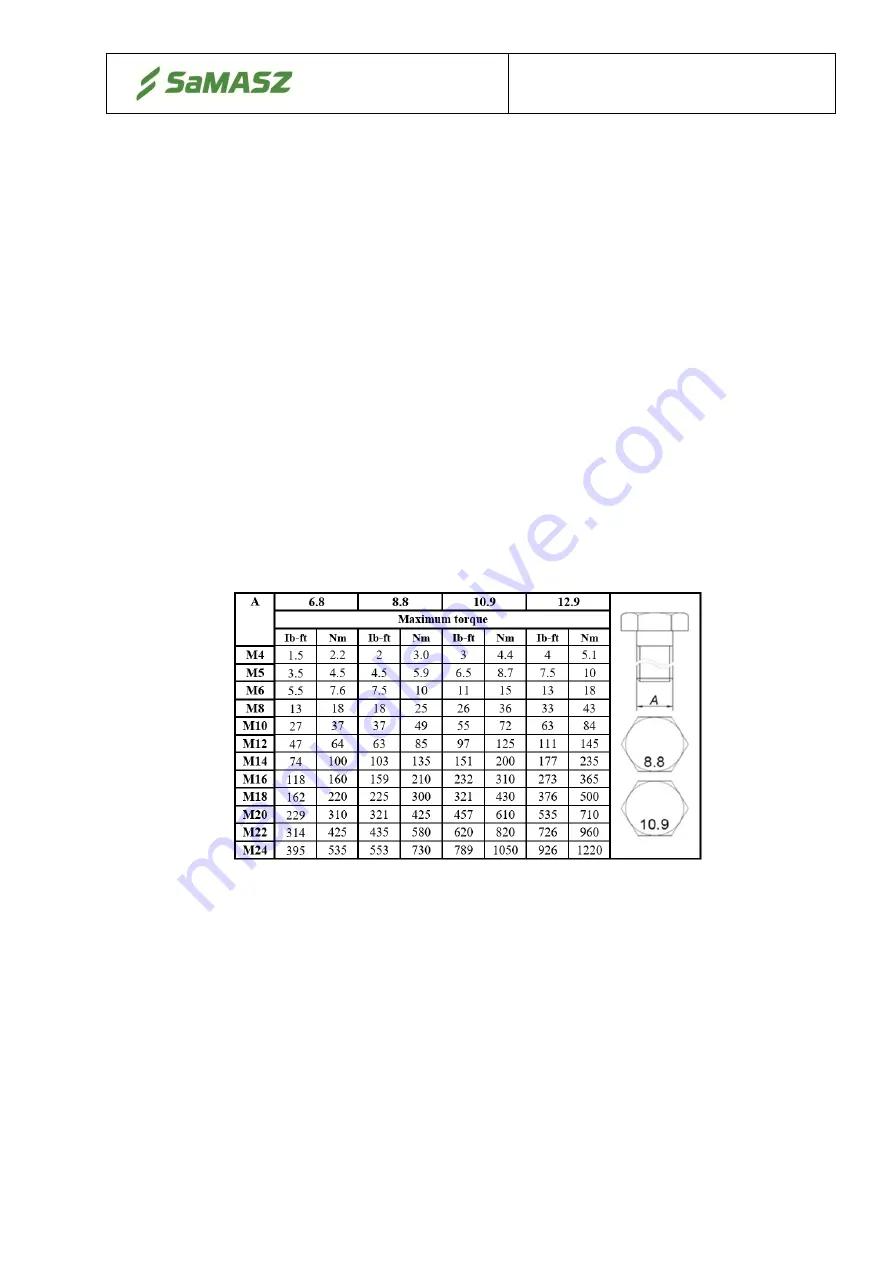

Make sure that all nuts and screws are tightened with correct torque (

Tab. 2

).

Examine technical condition of hydraulics and drive train as on daily basis.

Tab. 2.

Values of bolt tightness