22

FISHER

HYDRAULIC FRONT-LOADER EXTENSION ARM

OPERATOR'S MANUAL

❑

visually check technical condition of the hydraulics: fasteners for tightness. When any malfunctions

are found, tighten the fasteners and replace seals.

❑

check technical condition of connections between the machine and the vehicle.

5.7.2.

After-season maintenance

At the end of the season clean, wash and dry the machine. Carefully grease unpainted surfaces

and 3-point linkage pins.

Moreover:

❑

examine the paintwork condition. If necessary, clean and paint any damaged points,

❑

examine technical condition of the hydraulics as on daily maintenance. Moreover carefully check

the condition of hydraulic hoses. If necessary, replace them with new ones as required by the

manufacturer,

❑

examine the technical condition of the machine's moving parts. If any clearance on pins is found,

replace them together with sliding bushings and tighten,

❑

protect working parts (pins, joints, cylinder rods, etc.) against corrosion by applying a thin film of

solid grease on their surfaces.

5.7.3.

Storage

Disconnect the machine and set it on support feet. It is recommended to store the aggregate on

a paved ground, preferably in roofed places, inaccessible to unauthorized personnel and animals.

After storing for winter period, before operating the machine, check its technical condition while

paying special attention to the hydraulics. Touch up the paintwork, lubricate and check the condition of

hydraulic hoses.

6.

LUBRICATION

For machine lubrication use grease STP. Do not use any plant or animals based grease. Before

applying the grease, clean grease nipples and lubrication points.

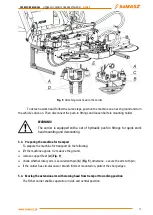

Lubrication points are shown in (

Fig. 15.

Lubrication points on Fisher carrier

x4