P5

BASIC MAINTENANCE

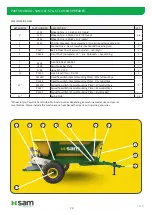

To keep your SAM Spreader in excellent working condition, please follow these basic maintenance

procedures as you go.

1.

Keep your machine fairly clean and very well greased.

2.

Before each use; check the hydraulic system for signs of oil leaks or wear. Check there is no play in the spinner

bearings by lifting up on the spinner discs. Tension the spinner bearings by tightening the large nyloc nut at

the top of the spinner shaft (this can be adjusted by undoing the grub screws).

3.

After every five hours of operation grease all nipples on the front and back floor shafts, and the four spinner

shaft bearings should be well greased.

4.

After every ten hours of operation check all bolts are tight, including the wheel nuts, joiners and

spinner discs and vanes. Check all nipples and grease points on the front floor adjusters slides,

drawbar jack, clutch pivot bearings, back door jack, hubs and tandem axle pivot points.

5.

The floor-belt should be tensioned with a 40mm sag below the middle of the chassis, with an even curve/sag

from front to back. Adjust when necessary.

6.

All roller chains should be kept well oiled, particularly during long periods of storage.

7.

Check the couplings above the spinner tubes stay approximately 2mm between the top and bottom halves.

8.

Keep conveyor greased and belt tracking in the centre of the rollers (by adjusting at the non-drive end).

9.

Check your linkage/tow pins.

10. Always ensure tractor oils are kept in excellent condition. Beware when changing a Spreader between

different tractors. Pump oil out of the hoses unless they use the same hydraulic oil.

11. If you have load cells, please make sure the bolts are regularly tightened.

12. Avoid high pressure hosing/waterblasting around your load cells, sensors and monitor if you have them.

13. Disconnect electronics when welding on this machine. Welding may destroy electronics.

Please keep these checks up for the lifetime of your SAM.

BASIC MAINTENANCE

WARNING

(Both may destroy electronics)

DO NOT WELD ON THIS MACHINE

DO NOT USE HIGH PRESSURE CLEANING

ON ELECTRONICS

(load cells, display, sensors or junction box)