3

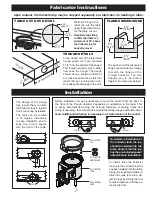

Fabricator Instructions

Installation

5

3

/

4

"

(14.61)

8

3

/

4

"

(22.23)

5

1

/

2

"

(13.97)

4"

(10.16)

The open end of the fabricated

trough should include a flange

to match the flange on the

Trough Collector. The two

flanges are to be butted

together and securely welded.

At the closed end of the fabricated

trough, punch a 2” hole, centered

1-1/4” from the bottom of the trough.

This location ensures proper water

flow down the trough. The trough

should have a minimum depth of

3” at the closed end and a fall of at

least 3/32” per running foot to en-

sure adequate drainage to the unit.

FLANGE DIMENSIONS

TROUGH DETAILS

6

1

/

2

"

(16.51)

12

1

/

4

"

(31.11)

ø20"

(ø50.75)

Before installation it may be necessary to move the control from the back to

the front of the Trough Collector depending on orientation in the table. This

is easily accomplished using the existing fasteners, mounting holes and

wiring. If necessary, the control can be mounted remotely using an optional bracket.

Note: Additional field wiring is necessary for remote location of the control.

CONTROL

CONTROL

CONTROL

CONTROL

Weld the Trough Col-

lector top into the table

using these dimensions

for the table cut out.

Note: Before welding

confirm that there is a

minimum of 22” above

the Collector top for

basket removal.

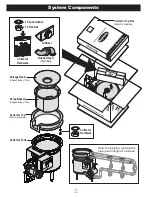

Upon request, the Collector top may be shipped separately to a fabricator for welding to table.

ADJUSTABLE

LEGS

COLLECTOR

TANK

COLLECTOR

HARDWARE

COLLECTOR

TOP

Note: Before installation of

the Collector tank, the top

should be welded into the

table. Confirm that the top

has the pre-installed gasket

affixed before installation.

To install, raise the Collector

tank up to the Collector top that

has been welded into the table.

Using the supplied hardware,

attach the tank to the top. Ad-

just the legs by turning the foot

counter clockwise until they ex-

tend to the floor.

The design of the trough

may require that you rotate

the Collector tank in relation

to the top during installation.

The tank can be rotated

in 15 degree increments

to ease installation and to

keep the control square

with the front of the table.

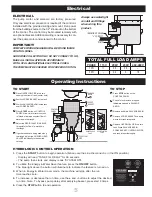

15˚

90˚

180˚

15˚

90˚

180˚

15˚

90˚

180˚

TABLE CUT OUT DETAIL

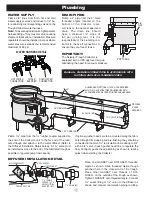

1¼”

3” M

in.

Cen

ter H

ole

Trough