4-4

Metal Detector

METARIDDER

D) The discharge damper is activated frequently or there is too much material discharged

improperly

Assumed Cause

Troubleshooting

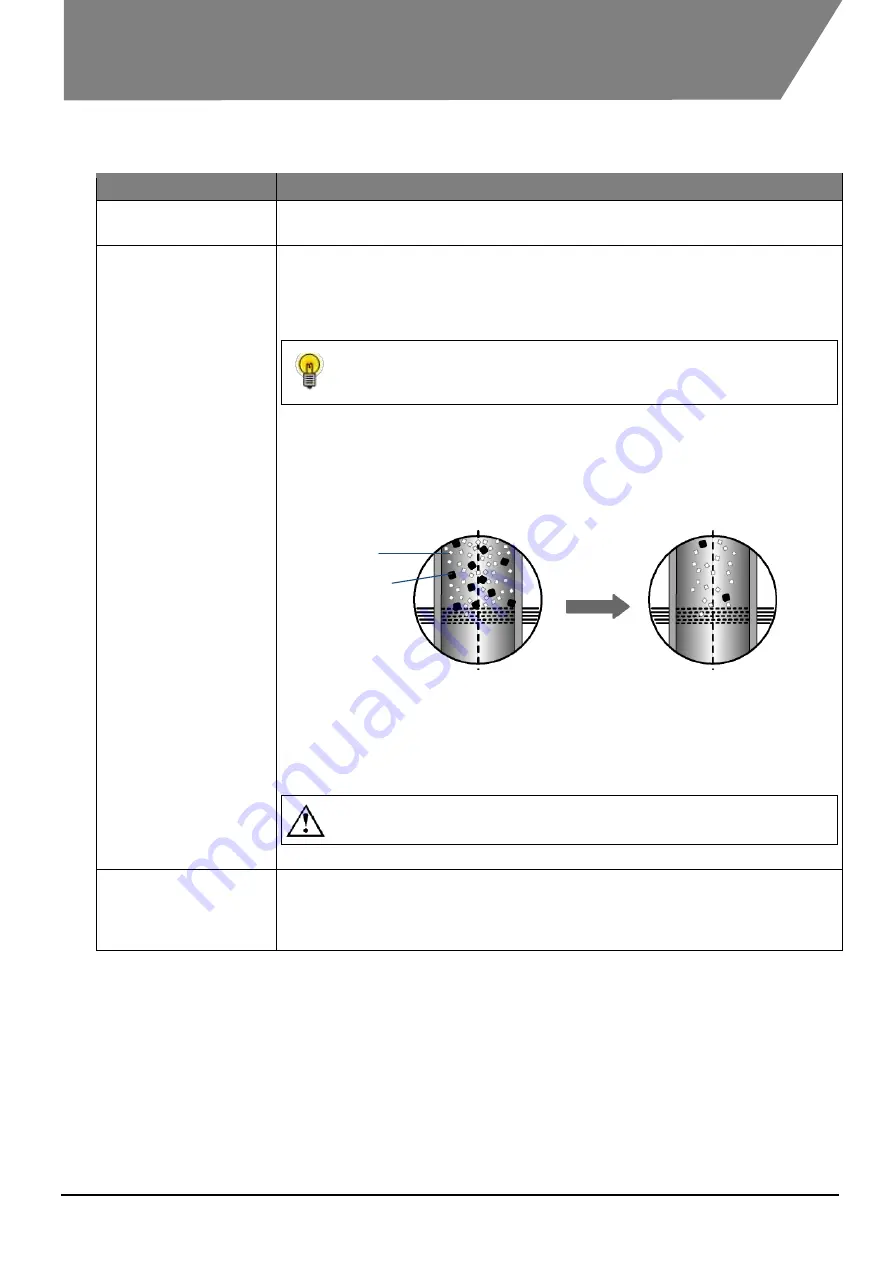

Metal pieces have attached

inside the sensor unit.

Clean the inside (the path of the material) of the sensor unit. (*1)

Too many metal pieces are

mixed in the material.

If there are too many metal pieces mixed in the material, it is possible that most of the material

are discharged as NG material because the discharge damper always turns to the discharge

chute due to frequent detection response of the sensor. If that was the case, take following

actions.

If there are too many metal pieces mixed in the material, performing a

pre-processing of reducing metal pieces with a magnet will help increasing the

effectiveness of the machine.

•

Reduce the amount of material fed to the machine

In using the machine with the specified sensitivity, reduce the amount of material fed to the

machine to reduce the number of detection responses. The optimum amount to be loaded

depends on the level of metal pieces in the material. Try reducing the amount of the material

little by little to find the optimum amount.

Reduce the amount of material being fed to reduce the number of metal pieces passing

through the sensor.

•

Set a higher threshold (the sensitivity will drop)

Make the threshold higher than the current setting. (*2)

CAUTION

Setting a threshold higher than the recommended value may lead to a

detection performance lower than those described in the specifications.

The threshold is not set

properly.

Threshold can be arbitrarily set by user. (*2)

A recommended value for this machine has been set before shipment.

If the threshold is set considerably lower than the recommended standard value (*3), the

discharge damper frequently operates, causing a discharge error.

Material

Metal piece