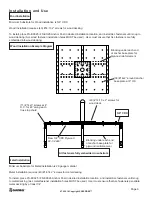

Concrete Installation

Metal Installation Example Diagram

All fasteners penetrate metal decking by at least 1/4”

20 Gauge

Concrete Installation Example Diagram

All fasteners minimum 3-1/2” embedment

Minimum 6” thick / 2,500 p.s.i.

Minimum Substrate for Concrete Installation is 6” thick, 2,500 p.s.i.

Concrete Installation requires (8) 1/2” Hilti HIT-Z Rods or equivalent, with minimum 3-1/2” embedment

To install, place FS-EX325 / FS-EX326 Anchor Post in desired installation location. Installation site must be a minimum 8”

from all edges. Install ALL fasteners until snug and ensure FS-EX325 is fully secured to concrete substrate. (ALL concrete

fastener installation holes MUST be used). User must ensure that ALL fasteners are fully embedded into concrete

substrate. User should always refer to fastener manufacturer’s instructions regarding fastener installation.

Inspection

User must inspect the FS-EX325 / FS-EX326 prior to each use for damage or deficiencies, including,

but not limited to, cracking, rust, corrosion, deformation, alteration, sharp edges, damage due to ex-

cessive heat, and missing or illegible labels.

Ensure that work area for intended installation of the FS-EX325 / FS-EX326 is free from damage or

conditions that would make the area unsuitable for installation. The user must ensure that the

structure to which the FS-EX325 / FS-EX326 is intended to be fastened to will support the application

specific loads covered in this manual.

A Competent Person other than the user must inspect the FS-EX325 / FS-EX326 at least every 6

months. These Competent Person inspections must be recorded in the Inspection Log included in

this manual and in the Inspection Table included on the product label.

While conducting inspections, the Competent Person must consider all applications and hazards that

the equipment may have been subjected to while in use.

V1.0 2018 Copyright SAFEWAZE™

Page 9