4

XL-AS20012BM-en-US Rev B · 2014-05-28 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND,

SAF, and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Decal Requirements

2. Standard Decal Requirements

The following five (5) decals MUST be properly installed on

the trailer prior to putting it in service:

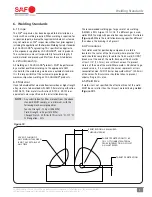

Tire Clearance Warning Decal: XL-AR356-01

(Figure 1)

.

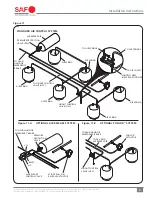

Air Release Warning Decal: XL-AR429

(Figure 2)

.

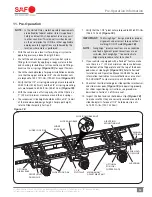

Manual QWIK RELEASE

®

Warning Decal: XL-MS184

(Figure 3)

.

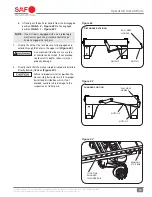

SwingAlign

™

Axle Alignment Decal: XL-AR372-01

(Figure 4)

.

Figure 1

WARNING

Minimum tire clearance

MUST

be maintained between tires and

nearest point of contact on the suspension or vehicle. Premature

tire wear, fire or loss of vehicle control could result from contact

with the tires if clearances are not maintained.

XL-AR356-01

TIRE CLEARANCE REQUIREMENTS

1 INCH (25.4 mm) MINIMUM VERTICAL

feature.

2 INCH (50.8 mm) MINIMUM LATERAL

Axle.

www.safholland.us

Copyright © 2011

#

SAF-HOLLAND, Inc.

Figure 2

WARNING

Failure to properly engage the lock pins could result in loss of vehicle control

which, if not avoided, could result in death, serious injury or property damage.

IMPORTANT: TRAILER EMERGENCY BRAKES MUST BE APPLIED BEFORE MANUAL

AIR RELEASE SWITCH WILL OPERATE.

TO REPOSITION SLIDER:

1. Remove stop bar and move to desired location.

2. Pull manual switch to

“disengaged”

position. (If lock pins do not

retract after manual switch is in

“disengaged”

position, gently rock

trailer and pins will automatically retract.)

3. Carefully move trailer until contacting stop bar.

4. Push manual switch to

“engaged”

position and visually check all lock

pins for proper engagement.

5. Locate stop bar directly behind slider.

6. Before using trailer, the manual air release lock switch must be in

“engaged”

position, and all lock pins must extend through the rails or beams.

AIR RELEASE SWITCH

PUSH TO

“ENGAGE”

LOCK PINS

PULL TO

“DISENGAGE”

LOCK PINS

XL-AR429

www.safholland.us

Copyright © 2012

#

SAF-HOLLAND, Inc.

Figure 3

TO REPOSITION SLIDER:

1. Remove stop bar and move to desired location.

2. Lift pull arm and pull until locked in the

“OUT”

position. (If lock pins do not retract

after pull arm is locked in the

“OUT”

position, gently rock trailer with brakes

applied and pins will automatically retract.)

3. Apply trailer brakes and carefully move trailer until contacting stop bar.

4. Release pull arm to the

“IN”

position and visually check all lock

pins for proper engagement.

5. Locate stop bar directly behind slider.

6. Before moving the trailer, the pull arm must be locked in the

“IN”

position, and all lock pins must extend through the rails or beams.

“IN”

POSITION

“OUT”

POSITION

XB-SL0255

XL-MS184

www.safholland.us

Copyright © 2012

#

SAF-HOLLAND, Inc.

WARNING

Failure to properly engage the lock pins could result in loss of vehicle

control which, if not avoided, could result in death, serious injury or

property damage.

Torque Decal: XL-AR418-01

(Figure 5)

.

It is the responsibility of the end user to periodically inspect

all decals and ensure that they are clean and completely legible.

If any decals are missing, loose, damaged or difficult to read,

contact SAF-HOLLAND

®

Customer Service at 888-396-6501 to

order replacements immediately.

Figure 4

ALIGNMENT BOLT IS ON THE FRONT OF THE ROADSIDE FRAME BRACKET:

XL-AR372-01

STEP 1.

Before aligning axle, pull trailer forward in a straight line for a sufficient distance to insure there are no binds

in the suspension and then lock the brakes so the slider lock pins rest against the rear of the body rail holes.

STEP 2.

Check to verify trailer is empty and emergency brakes are

NOT

engaged.

STEP 3.

Rotate bolt

CLOCKWISE

to move axle forward (A arrows);

COUNTERCLOCKWISE

to move axle rearward (B arrows).

A = axle forward

B = axle rearward

ALIGNMENT BOLT HEAD

NOTE:

1/2 turn of

free play in either

direction (A or B)

is acceptable.

SWINGALIGN

™

NON-WELDED AXLE ALIGNMENT PROCEDURES

www.safholland.us

Copyright © 2011

#

SAF-HOLLAND, Inc.