3

INTRODUCTION

•

This manual provides Use and Maintenance in-

structions, technical specifications, and safety pre-

cautions for reversible two-wheel tractor:

−

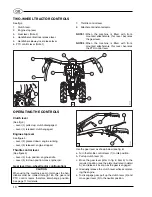

model SUPER SMART

in the versions with gasoline engine.

•

The first section of this manual provides technical

specifications and gives instructions relevant to

the machine. The second section of the manual

gives further details on individual attachments,

and provides all specific operating instructions.

•

Read this USE and MAINTENANCE Manual care-

fully before using your new two-wheel tractor. This

manual provides the most up-to-date information

on your two-wheel tractor available at the time of

going to press. Manufacturer reserves the right to

modify this document at any time without prior no-

tice.

•

AFTER-SALES SERVICE. Use only original spare

parts. The use of non-original parts voids the war-

ranty. When ordering spare parts, specify:

−

two-wheel tractor serial number;

−

part code of spare part required;

−

quantity or number of parts required.

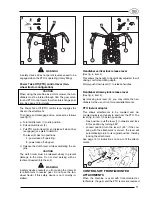

SAFETY REGULATIONS

GENERAL NOTICES

Any engine driven machine can become dangerous if

used incorrectly. Pay particular attention to the in-

structions in this manual marked:

WARNING

This symbol means that failure to observe the regula-

tion could cause injury or even death to the operator.

PRUDENCE

Prudence is the Golden Rule to prevent accidents.

TRAINING

The two-wheel tractor must only be used by respon-

sible people trained in the use of the machine and

duly authorized to use it.

MACHINE AND

ENGINE MANUALS

Read those MANUALS carefully before starting, us-

ing, servicing, refuelling or carrying out any work on

the two-wheel tractor.

DECALS

Read all the decals attached to the two-wheel tractor

and follow their prescriptions before starting, driving,

refuelling or servicing the machine. Replace immedi-

ately any damaged or illegible decals.

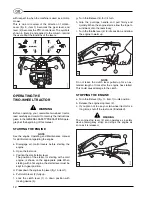

SUITABLE CLOTHING

•

Do not wear wide and flapping clothes that could

be caught in moving parts.

•

Always wear robust gloves when servicing the

two-wheel tractor or coupling attachments.

•

Do not operate your two-wheel tractor barefoot,

wearing sandals or shorts. Wear heavy shoes and

trousers.

PHYSICAL CONDITION

Do not drive the two-wheel tractor if your physical

condition is not suitable.

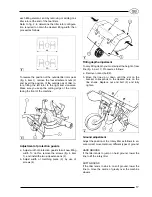

NOISE

In order to reduce the problems deriving from the

noise of the machine:

•

Do not work with the engine at maximum RPM

range.

•

Keep the blade head and the blade holder ad-

justed.

•

When using the machine for a long time, use ear

protections.

ENGINE

RPM

Do not change the injection system in an attempt of

increase max. engine Rpm.

FIRST AID

It is good operating practice to have a first aid box on

the two-wheel tractor.

SAFETY

DEVICES

•

Do not use the two-wheel tractor if the safety de-

vices are missing or defective..

•

Do not interfere with safety devices.

Summary of Contents for SUPER SMART

Page 1: ...SUPER SMART SUPER SMART Diesel USE AND MAINTENANCE MANUAL GB...

Page 2: ......

Page 24: ......

Page 25: ......

Page 26: ......