■

TABLE ADJUSTMENT

•

Height Adjustment (Fig 1)

To adjust up or down, loosen

the clamping lever, them adjust

the table to the desired position

and re-tighten clamping lever

securley.

•

Tilting Adjustment

(Fig 2 & 3)

Loosen pivot bolt. Tilt table to

desired angle up to 45° and

re-tighten bolt.

•

Swing 360°:

Loosen clamping lever then

swing table to appropraite

position and retighten.

•

Rotate 360°:

Loosen clamping lever, rotate

table to desired position and

retighten.

■

DEPTH ADJUSTMENT

•

Feed Depth Adjustment

(Fig 4)

Lower spindle assembly to

desired depth and spin down

nut. If nut moves due to vibra-

tion, spin down second nut and

lock in position by holding the

lower nut and tightening upper

nut.

•

Speed Adjustment (Fig 5)

Open pulley cover. Loosen

shifter bar. Choose speed for

drilling operation and move belt

to correct position for desired

speed. Push motor backward

until moderate belt tension is

acquired. Tighten shifter bar.

•

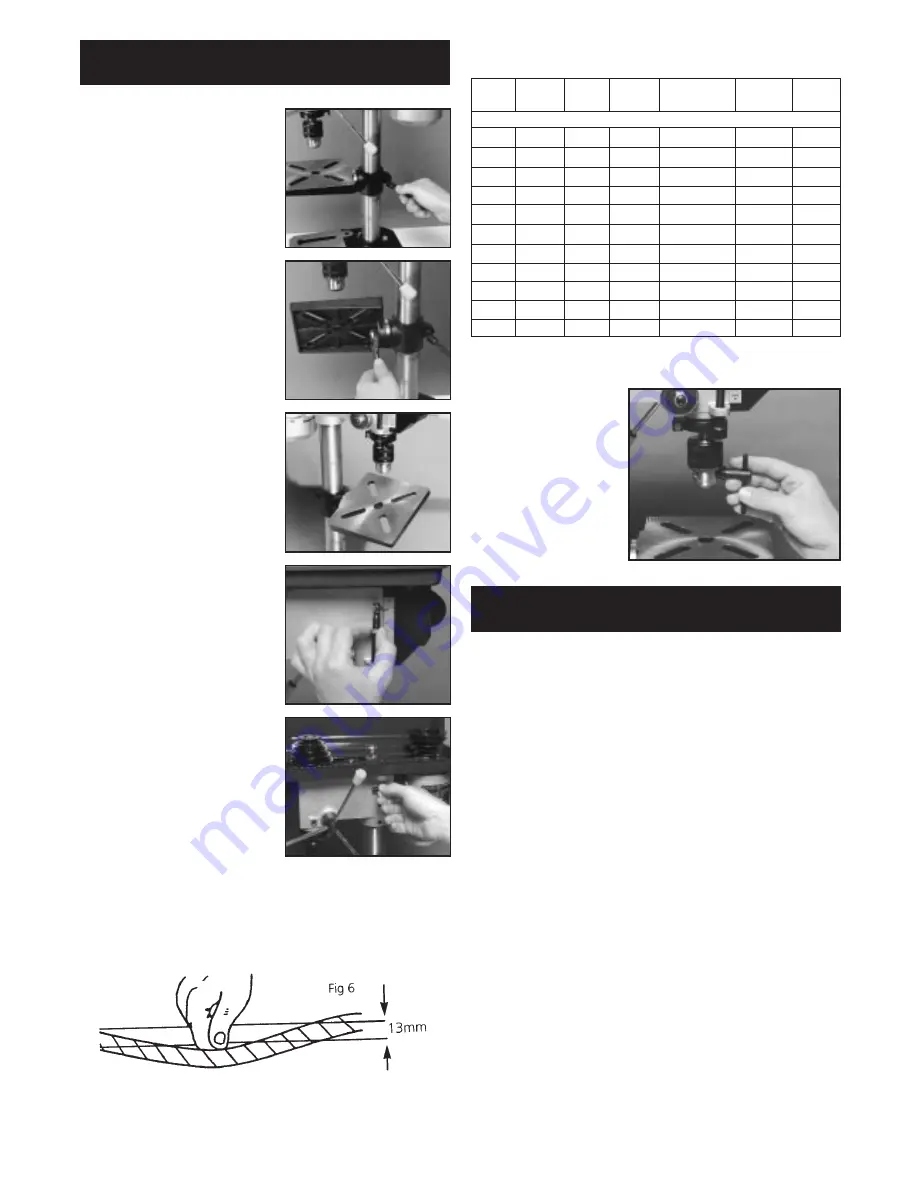

Belt Tension Adjustment

(Fig 6)

To guage proper belt tension,

use pressure to push down

with the thumb thumb on the belt at midway point

between the two pulleys. The belt should push down no

more than 13mm.

■

INSTALLING DRILL BITS

Open chuck jaws with chuck key (Fig.7).

Insert drill bit into chuck

jaws approx. 25mm.

When using a small drill

bit, do not insert it so

far that the jaws touch

the arbor of the drill.

Make sure that the drill

bit is centred in the

chuck before tightening

the chuck with the key.

Tighten all 3 holes.

■

DRILLING

Use clamps to hold the workpiece when drilling. The

workpiece should never be held by hand as the lips of the

drill may seize the workpiece at any time, especially

when breaking through the stock.

If the workpiece is whirled outof the operators hand,

injury may occur.

For flat work, lay the workpiece on a wooden base and

clamp it firmly down against the table to prevent it from

turning.

•

Using Vice

For small workpieces that cannot be clamped to the

table, use a drill press vice (not included). The vice must

be clamped or bolted to the table.

•

Positioning Workpiece

Always place a piece of wood on the table. This will pre-

vent splintering or making heavy burs on the underside

of the workpiece as the drill breaks through. The wood

must contact the left side of the column.

•

Round-Out Tolerance

For drilling operations requiring close tolerances, place

drill blank into chuck and check run out with a dial indica-

tor. If the run out is not within desired tolerance, tap the

chuck bottom with a rubber mallet until you get the

desired tolerance.

ADJUSTMENT

The proper drill speed for a given drill bit size

is as follows:

DRILL

STEEL

CAST

METAL

ALUMINIUM

PLASTIC

WOOD

DIA

IRON

(mm)

ROTATIVE SPEED R.P.M.

3

2500

2500

2500

2500

2500

2500

4

2500

2500

2500

2500

2500

2500

5

1750

2500

2500

2500

2500

2500

6

1750

2500

2500

2500

2500

2500

7

1250

1750

2500

2500

2500

2500

8

1250

1750

2500

2500

2500

2500

9

900

1250

1750

2500

2500

2500

10

900

1250

1750

1650

2500

2500

11

625

900

1250

1250

1750

1750

12

625

900

1250

1250

1750

1750

13

625

625

900

1250

1250

1750

OPERATION

Fig 1.

Fig 2.

Fig 3.

Fig 4.

Fig 5.