HEAVY DUTY

SOD CUTTER

34

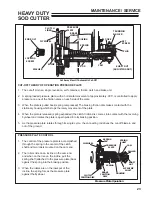

18. Re-assemble in reverse procedure using new

seals and gaskets.

19. After installation of the drive gear and shaft,

check the end play on the shaft. End play cannot

exceed .005" (.13mm). If adjustment is required,

add or remove shims (behind bearing cage) to

obtain correct measurement. Be sure to keep an

equal amount of shims on each side of shaft.

20. After installation of pulley shaft, check for proper

clearance between dog clutch faces. With

the blade shifter handle "Engaged", measure

between the dog clutch faces. Remove or add

shims to obtain .015" (39 mm) clearance

(Figure 8)

21. Check gear adjustment screw for proper

adjustment. To adjust screw, loosen locking nut

and tighten screw against gear. Torque screw to

10 ft-lbs (14 N·m).

22 Back adjusting screw out until 1/16" (1.59mm) is

obtained between screw and gear. (Figure 9)

23. Tighten locking screw.

ADJUSTING

SCREW

1/16”

.015” CLEARANCE

BETWEEN

DOG CLUTCH FACES

FIGURE 9

MAINTENANCE / SERVICE

Summary of Contents for 544853G

Page 2: ......