41

CAHA Midi

Installation, Usage and Maintenance Instructions

7.2 ADJUSTMENT % CO

2

AND CHECK INPUT

The boiler is equipped with an automatic gas/air regulator. This means that the amount of gas is regulated depending on

the amount of air. The % CO2 needs to be adjusted according to the table below ;

Type of boiler

Gas type

Inlet pressure

%CO

2

on max load

%CO

2

on min load

340

G20 / G25

20 / 25 mbar

9.3 +0.2-0.05

9.1 +0.15-0.2

425

G20 / G25

20 / 25 mbar

9.3 +0.2-0.05

9.1 +0.15-0.2

510

G20 / G25

20 / 25 mbar

9.3 +0.2-0.05

9.1 +0.15-0.2

600

G20 / G25

20 / 25 mbar

9.3 +0.2-0.05

9.1 +0.15-0.2

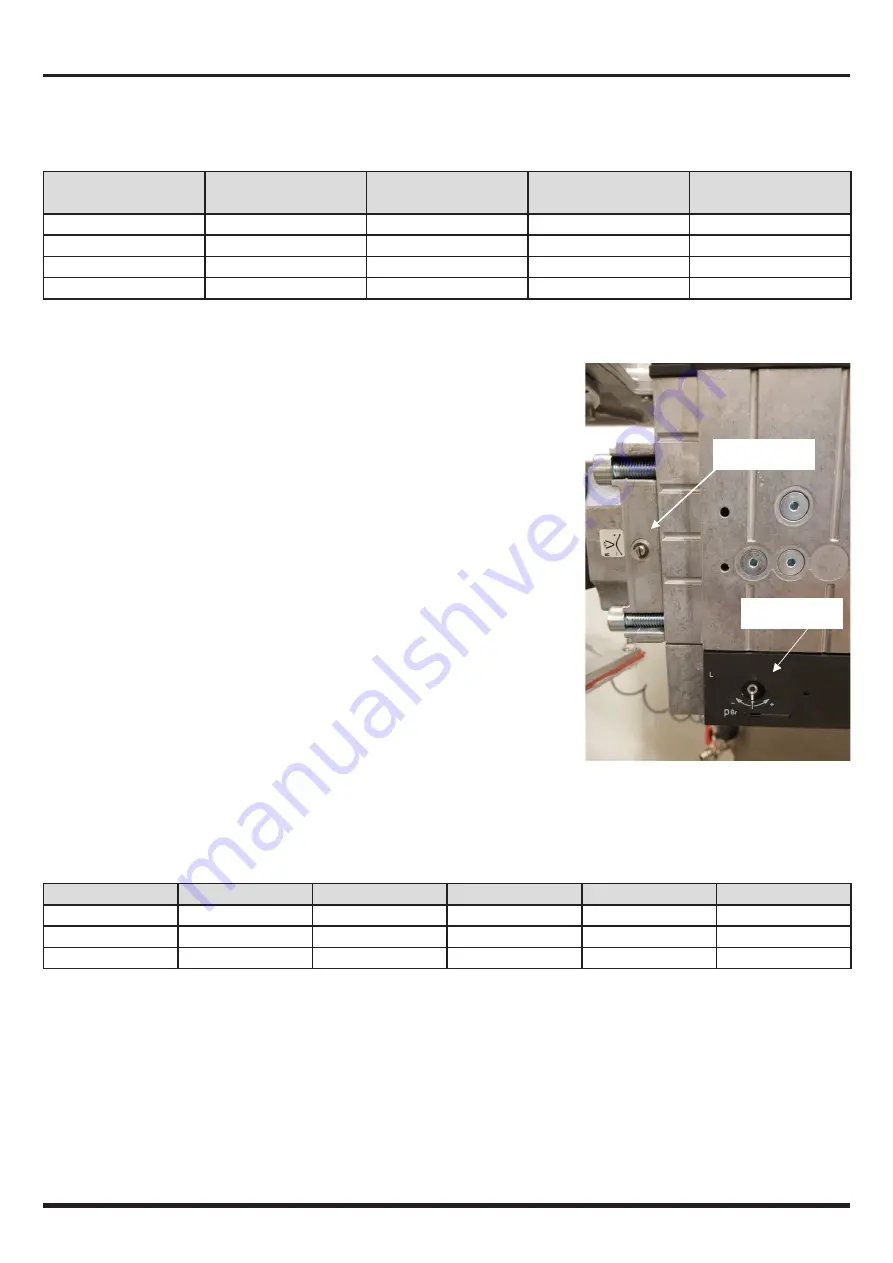

The boiler has a gas valve that is connected to a venturi. See figure below.

ADJUSTMENT FOR MAX. LOAD

• Wait until the boiler is stable and measure % CO

2

• If required, correct CO

2

with the throttle ; turning t gives a higher

CO

2

percentage (a ½ turn (180°) causes a change of approximately 0,85 %

CO

2

)

•

ADJUSTMENT FOR MIN. LOAD

• Wait until the boiler is stable

• If required, correct the CO

2

with the off-set ; turning t gives a higher

CO

2

percentage. Note : this offset adjustment is very sensitive : half a turn

(180°) causes a change of approximately 1 % CO

2

.

CHECK ON HEAT INPUT

In the table below the relationship between nominal input and fan speed and gasflow is given. The nominal fan speed can

be ± 5% due to adjustments in production

Model

340

425

515

600

Nominal input

340

425

515

595

[kW Hi]

Fan speed nominal

4600

4600

4600

4600

[rpm]

Gasflow G20

36

45

54

63

[m3/h]

If the gas flow is too low it may be due to an obstruction (dirt) in the air/flue system. Check and if necessary clean. The gas

flow must then be re-checked.

Throttle

Off-set