INSTALLATION

OPERATION

STEP 1:

Park RV on level ground. Prevent wheels from rolling by activating emergency brake and/or by using tire

chocks.

STEP 2

: BEFORE PROCEEDING TO INSTALLATION - PERFORM THIS IMPORTANT TEST

To insure clearance for the jack in the closed position, clamp the jack to the vehicle frame using two “C” clamps or

Vise Grips™. Close the jack with the crank handle and check to insure that the location chosen will allow the jack to

close without coming into contact with or obstruct any under chassis components (ie: plumbing, exhaust, etc.)

- Open the jack until it touches the ground. Recheck location and adjust as needed.

- Once in place, apply enough pressure so jack cannot move during installation procedure. Remove clamps or Vise

Grips™.

BOLT-ON INSTALLATION

WARNING:

BEFORE DRILLING HOLES, BE SURE THE DRILL

WILL NOT DAMAGE UNDER CHASSIS COMPONENTS

WHICH MAY BE ROUTED INSIDE VEHICLE FRAME (ie:

electrical, gas, water, generator fuel lines, holding tank

plumbing, water heater).

Refer to

STEP 1

and

STEP 2

above.

STEP 3:

Using the mounting plate as a template, mark the

locations of the four mounting holes on the vehicle frame.

Remove the jack.

STEP 4:

Mark the center of each hole location with a center

punch and hammer.

STEP 5:

Drill a 1/8” pilot hole and finish by drilling holes

with a 5/16” diameter drill.

STEP 6:

Reposition jack. Use a 9/16” socket and ratchet to

install the jacks to the vehicle frame using four screws and

four lock washers per jack (Figure 1).

WELD-ON INSTALLATION

Refer to

STEP 1

and

STEP 2

above.

STEP 3:

Weld each mounting plate to the vehicle frame

with 4 each 1” welds, as shown (Figure 2).

STEP 1:

Park RV on level ground, prevent wheels

from rolling, use tire chocks.

STEP 2:

Level trailer fore and aft using tongue jack

or landing gear.

STEP 3:

Check level gauge for low side of trailer,

crank down stabilizers on low side first, bringing the

trailer to a fine level position.

STEP 4:

Crank down stabilizers on opposite side of

trailer to insure maximum stability. Then re-snug

stabilizers on low side of trailer if necessary.

NOTE:

BEFORE MOVING TRAILER: Crank up stabilizers

to fully closed position and tighten 1/4 turn to secure in

travel position (this prevents stabilizers from working open

due to road vibration).

MAINTENANCE:

Use small amounts of WD-40 or similar

lubricant on drive screw threads and bolt locations as

required.

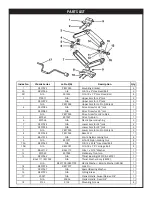

Figure 1

Figure 2

WARNING:

DO NOT

ATTEMPT TO USE THIS SCISSORS JACK TO LIFT EXCESSIVE WEIGHT OR TIRES OFF OF THE

GROUND - VEHICLE FRAME AND DOOR JAMB DAMAGE MAY OCCUR. USE ONLY STOCK HANDLE SUPPLIED.

DO NOT USE A CHEATER BAR ON HANDLE. DO NOT USE THIS SCISSORS JACK AS A TIRE CHANGING JACK.