8

It is necessary that the rings be cut to the correct size,

otherwise service life is reduced.

4. Install one ring at a time. Make sure it is clean and

has not picked up any dirt in handling. If clean oil is

available, lubricate the shaft and the inside of the

stuffing box.

Seat rings firmly. (Except for TFE filament and graph-

ite yarn packings which should be snugged up very

gently. Then wrench in gradually...after the pump is

back in operation.) Joints of successive rings should

be staggered and kept at 90

O

apart. Each individu-

al ring should be firmly seated with a tamping tool.

When enough rings have been individually seated so

the nose of the gland (#9) will reach them, individual

tamping should be supplemented by the gland. Nev-

er depend entirely on the gland to seat a set of rings

properly - this practice will jam the last rings installed

but leave the bottom rings loose in the box.

5. After the last ring is installed take up bolts finger

tight or very slightly snugged up. Do not jam the

packing into place by excessive gland loading. Start

pump, and take up bolts until leakage is decreased to

minimum. Make sure gland bolts are taken up evenly,

stopping leakage entirely at this point will cause the

packing to burn up.

6.

Allow packing to leak freely when starting up a newly

packed pump. Excessive leakage during the first hour

of operation will result in a better packing job over a

longer period of time. Final adjustment should allow

approximately 30 drops per minute to leak from the

packing.

7. When specified, Gusher can provide means of lu-

bricating the shaft and packing through a lantern ring

by supplying water, oil, grease, or liquid handled in the

pump.

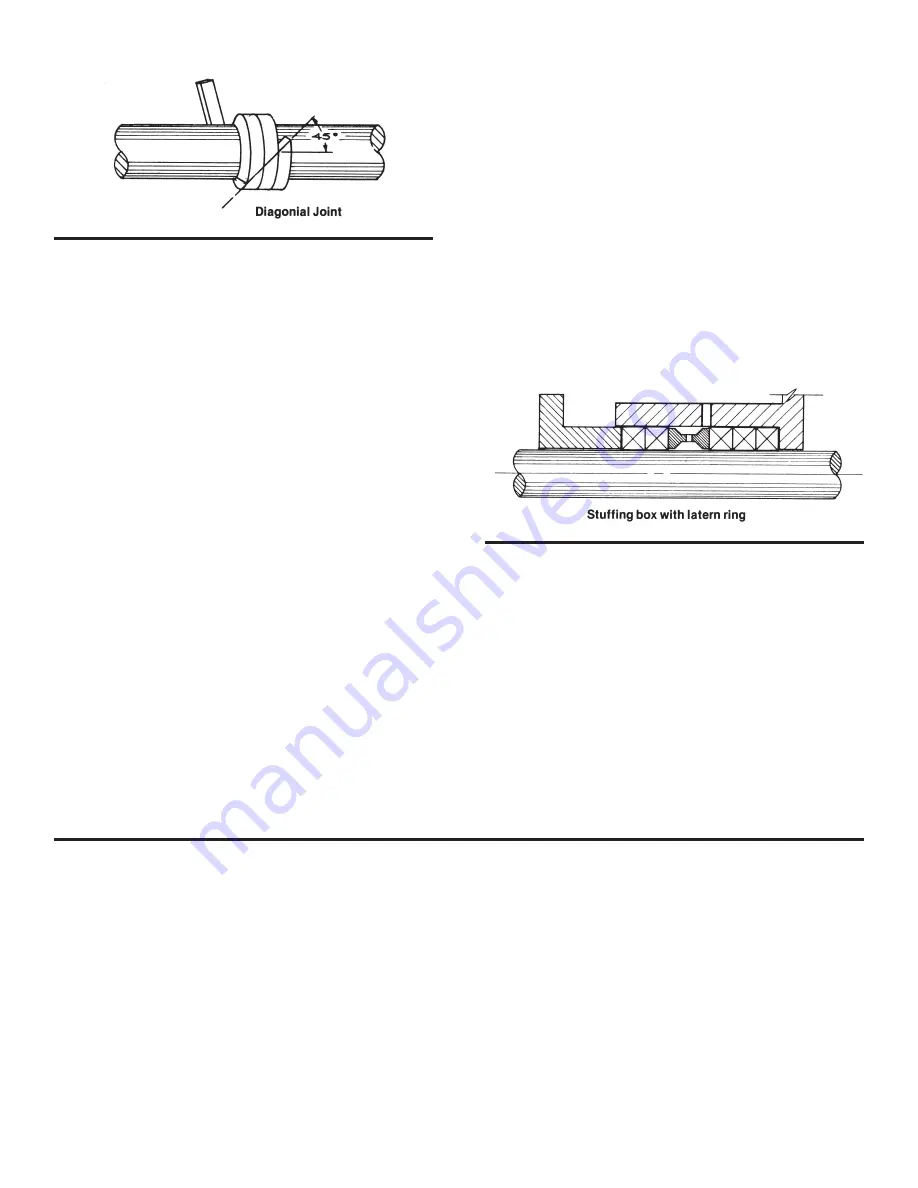

8. If the stuffing box has a lantern ring, make sure the

lantern ring, as installed, is slightly behind the fluid inlet

so it will move under the inlet as gland pressure is ap-

plied. (See illustration below.)

9. Replace packing when leakage cannot be con-

trolled by further takeup on the gland.

Some of the most common reasons for packing failure

are:

1. Improper installation

2. Uneven gland adjustment

3. Shaft misalignment and shaft whip

4. Improper selection of packing for liquid

5. Improper selection for pressure and temperature

6. Contaminated liquid (dirt, abrasives, etc.)

MECHANICAL SEAL

The most important factor in mechanical seal, other than

the sealing qualities, is the fact that once it has been prop-

erly installed there is little or no maintenance required.

Some of the most common reasons for seal failure are:

1. Improper installation

2. Shaft misalignment and shaft whip

3. Wrong selection for liquid pumped

4. Wrong selection for pressure and temperature

5. Dirt or grit between faces

6. Seal gland (#9) tightened unevenly so stationary seat

is not perpendicular to shaft.

7. Operation without fluid