Step-by-Step InSTrUCTIonS

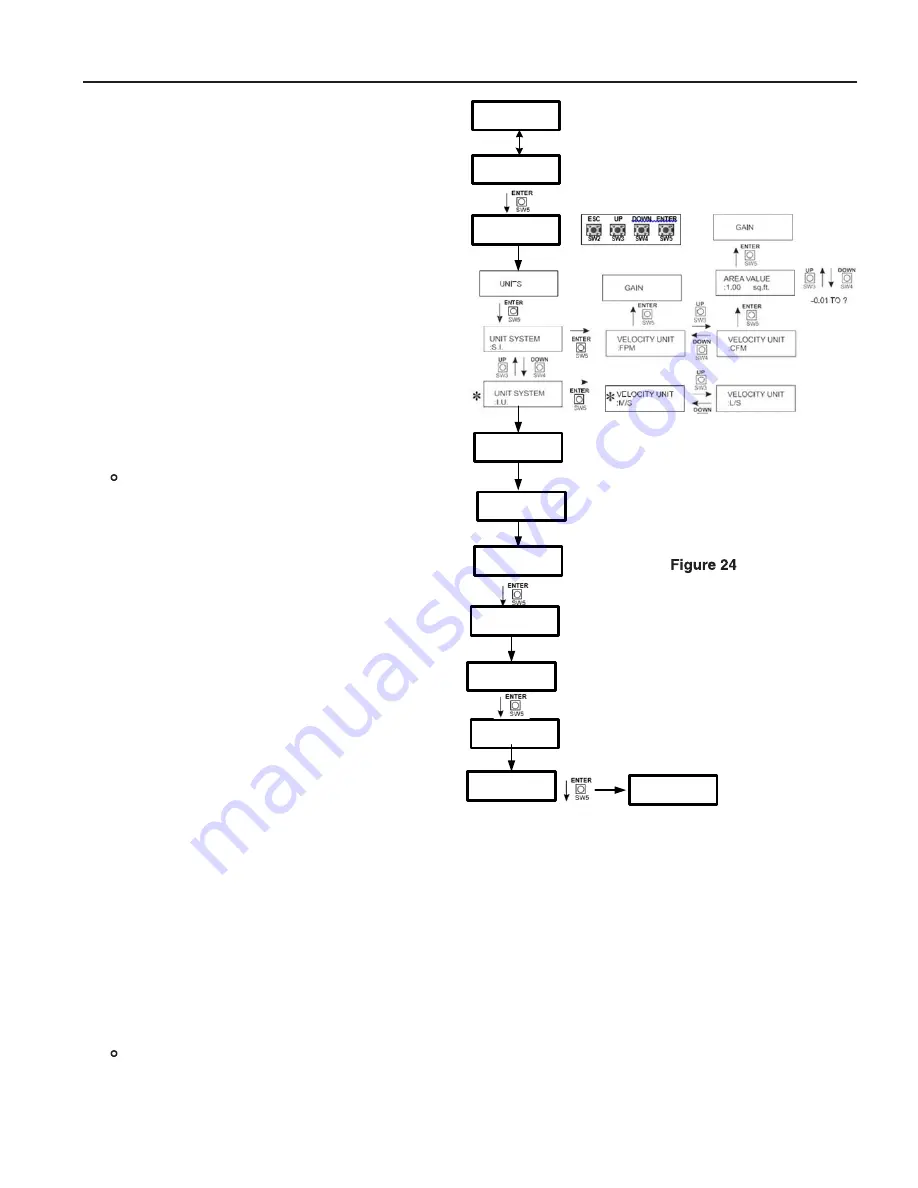

(see Figure 24)

When power is applied for the first time the display

will first show firmware revision number and then the

display will eventually read “INITIAL STARTUP FIELD

CALIBRATE” and alternately read “HOLD ENTER KEY

COMPLETE SETUP” (If this is NOT displayed then

see SETUP AND ADJUSTMENTS, RESET SETTINGS,

select UNITS and then scroll to BALANCER FIELD CAL-

IBRATION and select ON.)

• When the “ENTER” button is depressed the display

will read “FIRST STEP SETUP UNITS.”

• Depress “ENTER” and use the ESC UP DOWN and

ENTER buttons, when “UNITS” is displayed to se-

lect desired units for calibration to match T&B units.

“GAIN” is always 1 and the area is the total area

through the fan inlet(s).

• After units have been selected the transmitter will

show “SECOND STEP CALIBRATION” briefly and

then show “RUN FAN MINIMUM SPEED” followed

by “MIN FLOW POINT” continuously.

At this point the fan must be running at the first

flow or the minimum fan speed or lowest operat-

ing point for the system. Note: The point must

be on the fan curve and not simply the lowest

speed the variable speed drive is able to run. This

point is typically between 15HZ and 30 HZ even

though the VFD might be able to run slower. Air

flow values below the minimum operating point

on the fan curve stir the air but may not move any

air and will produce poor calibration results.

• With air passing across the sensors at the minimum

air flow, adjust the transmitter display using the up

and down buttons until the value displayed matches

the known air flow at this fan speed and press the

“ENTER” button.

• The display will briefly display “RUN FAN MIDDLE

SPEED” followed by “MID FLOW POINT” continu-

ously. Increase the fan speed to the second op-

erating air flow point. With air passing across the

sensors at the middle speed, adjust the transmitter

display using the up and down buttons until the

value displayed matches the known air flow at this fan speed and press the “ENTER” button.

• The transmitter will briefly display “RUN FAN MAXIMUM SPEED” followed by “MAX FLOW POINT” continuously.

Increase the fan speed to the maximum expected operating air flow. With air passing through the sensors at the

maximum expected operating air flow, adjust the transmitter display using the up and down buttons until the

value displayed matches the known air flow at this fan speed and press the “Enter” button. The transmitter dis-

play will show “CYCLE POWER” and will automatically cycle or can be turned off and backed on to enter normal

operating mode. DO NOT TURN OFF BALANCER FIELD CALIBRATION MODE.

• Turn the fan off and close any dampers to prevent any air movement through the fan. With no air passing through

the fan or the fan blocked off, use the up or down button to scroll through each sensor and note highest value

displayed.

• Use the ZERO CUTOFF feature to enter a value greater than the highest value displayed on any one sensor.

Please NOTE: Previous balancer settings are lost when the field calibration mode is turned off.

To repeat the calibration steps again the field calibration mode can be turned off and then on again to

repeat the setup steps using fan speeds and conditions previously established as known air flow values for

low, medium and high.

INITIAL STARTUP

FIELD CALIBRATE

HOLD ENTER KEY

COMPLETE SETUP

FIRST STEP

SETUP UNITS

SECOND STEP

CALIBRATION

RUN FAN

MINIMUM SPEED

MIN FLOW POINT

?????

MID FLOW POINT

?????

RUN FAN

MIDDLE SPEED

MAX FLOW POINT

?????

RUN FAN

MAXIMUM SPEED

CYCLE POWER

rUSKIn EFAMS ThErMAl DISpErSIon AIrFlow MEASUrIng SYSTEM InSTAllATIon InSTrUCTIonS

9