5

VLBG-PLUS

WARNING

Observe the requested torque value before

each lifting or turning operation.

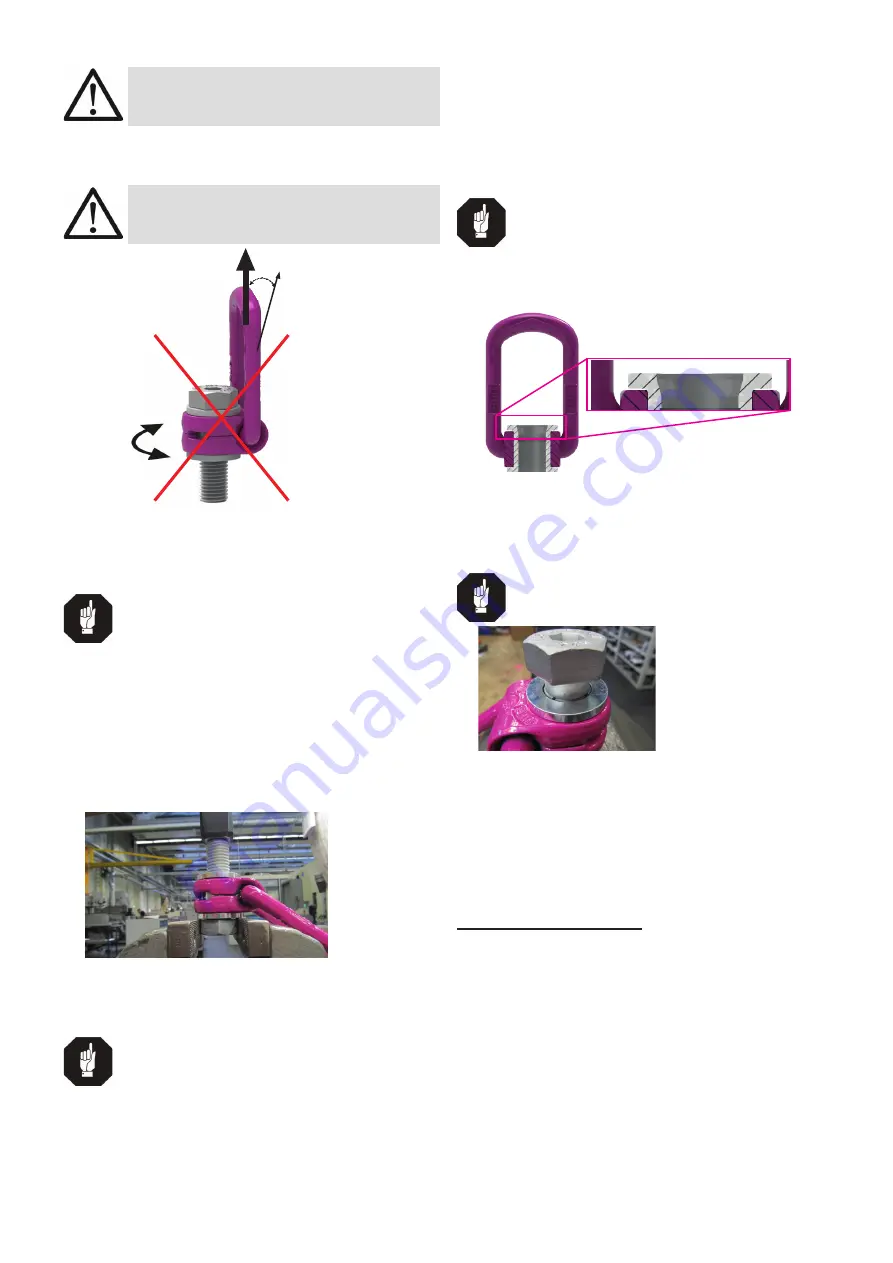

3.3.3 Forbidden lifting and turning operations

The following operations are forbidden:

WARNING

The turning of the VLBG-PLUS under load in

the direction of the bolt axle (+15°) is forbidden.

F

15°

Pic. 7: Forbidden turning direction at loading in the

direction of the axle.

3.4 Dismantling / Assembling the RUD bolt

HINT

The dismantling / assembling and/or the ex-

change of the RUD bolt must only be executed

by a competent person!

3.4.1 Dismantling the bolt of the

VLBG-PLUS M8-M48

1. Position VLBG-PLUS with the thread end upwards

at the bushing on the top of the bench vice without

clamping the hexagon head of the bolt.

2. Slightly hit the bolt from the top to drive it out from the

bushing (Pic. 8).

Pic. 8: Dismantling position of the VLBG-PLUS

3.4.2 Assembling the bolt of the

VLBG-PLUS M8-M10

HINT

Only the appropriate strength class of bolt for

each specific size must be used!

M8-M10: ICE-Bolt only!

1. Insert the bolt into the drill hole in the socket until the

retaining ring is positioned on the socket

2. Squeeze the retaining ring together with flat pliers so

that it sits deeply in the groove of the nut.

3. Now insert the bolt with light hits with a hammer fully

into the socket.

4. Finally, control the tightness of the bolt. The bolt must

be easily rotatable by 360°.

3.4.3 Assembling the bolt for

VLBG-PLUS M12-M48

HINT

Only the stated strength of class for the respec-

tive size of the bolts must be used!

M12-M24: ICE-Bolt | M27-M48: 10.9

1. Insert the bolt into the bushing at the tapered end,

where the chamfer is (refer to Pic. 9).

Pic. 9: VLBG-PLUS in sectional view.

The insertion chamfer is visible on top of the bushing

2. Insert the bolt into the socket in such a way that the

retaining ring is circumferential deepened in the socket

and seated (refer to Pic. 10).

TIP

Turn the bolt a few times under slight pressure

so that it is centered in the retaining ring!

Pic. 10: Retaining ring positioned as circumferential in the

recess

3. Use a light tap on the head of the bolt so that the bolt

can be assembled up to the end stop of the bolt head

on the socket.

4. Finally, control the tightness and seating of the bolt.

The bolt must be easily rotatable by 360°.

4 Inspection / repair

4.1 Hints for periodical inspections

The operator must determine and specify the nature

and scope of the required tests as well as the periods

of repeating tests by means of a risk assessment (see

sections 4.2 and 4.3).

The continuing suitability of the anchor point must be

checked at least 1x year by an expert.

Depending on the usage conditions, f.e. frequent usage,

increased wear or corrosion, it might be necessary to

check in shorter periods than one year. The inspection has

also to be carried out after accidents and special incidents.