7

DVNI 315 D2 F4 30

15.11.2017

ID 144 618

SN 180912-Q00000-123

ISO F

2870 1/min

1100W

50/200°C

2,3A

50Hz

n

N

P

1N

t

A

/t

M

I

max.

400V 3~Y

VSD not integrated

N= 71

η=61,4% (A,static)

ErP Data

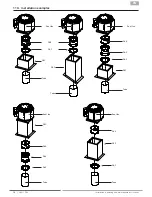

DVN...D.F4

DVNI...D.F4

EN

5.3. Nameplate

ATTENTION! The information on the nameplate must always be observed!

Legend:

■

I

max

Max. current consumption

■

t

A

/ t

M

Max. ambient temperature / Max. medium temperature

■

P

1N

Rated power consumption

■

n

N

Rated speed

■

IPX4

IP protection complete device

■

ISO F

Insulation class motor

■

ErP Data ErP Conformity, if required according to Reg. 327/2011

■

η

Overall efficiency

■

N

Efficiency at the optimum energy efficiency

■

ID

Item number

■

SN

Serial number

Air direction arrow

ErP 2015

Catalog item number

Test date

CE mark

Grounding

Series

perm. temperature /

time in smoke extraction

perm. temperature in

continuous operation

■

DVN...D.F4

+400°C / 120 min

-20°C bis +200°C

■

DVNI...D.F4

+400°C / 120 min

-20°C bis +200°C

5.1. Permissible conveying medium temperatures

5.2. Certification

The testing and factory certification required by EN 12101-3:2015 was carried out at the Slovenian National Building

and Civil Engineering Institute (ZAG).

Certificate Number: 1404-CPR-3027

To find under: www.zag.si/en/certificates

Roof fans 200 °C - vertical discharge 3.000-31.500 m³/h, with backward curved impeller blades

Insulated roof fans 200 °C - vertical discharge 3.000-31.500 m³/h, with backward curved impeller blades

6. DELIVERY CONTENTS

■

1 x Exhaust fan

■

1 x Installation, operating and maintenance instructions

■

Declaration of conformity

■

Declaration of incorporation

www.ruck.eu |

Summary of Contents for DVN***D.F4 Series

Page 19: ...19 EN Notes www ruck eu...