5

P/N 1011283 Rev. A 03/15

INSTALLATION

1. Remove unit and all packing mate-

rials from shipping carton.

2. Open the Accessories Box. It should

contain the following:

a. Bun Chute

b. Bun Feeder

c. 1 Belt Set

d. Owner’s Manual

NOTE:

If any parts are missing or dam-

aged, contact Antunes Techni-

cal Service IMMEDIATELY at

1-877-392-7854 or 1-630-784-

1000.

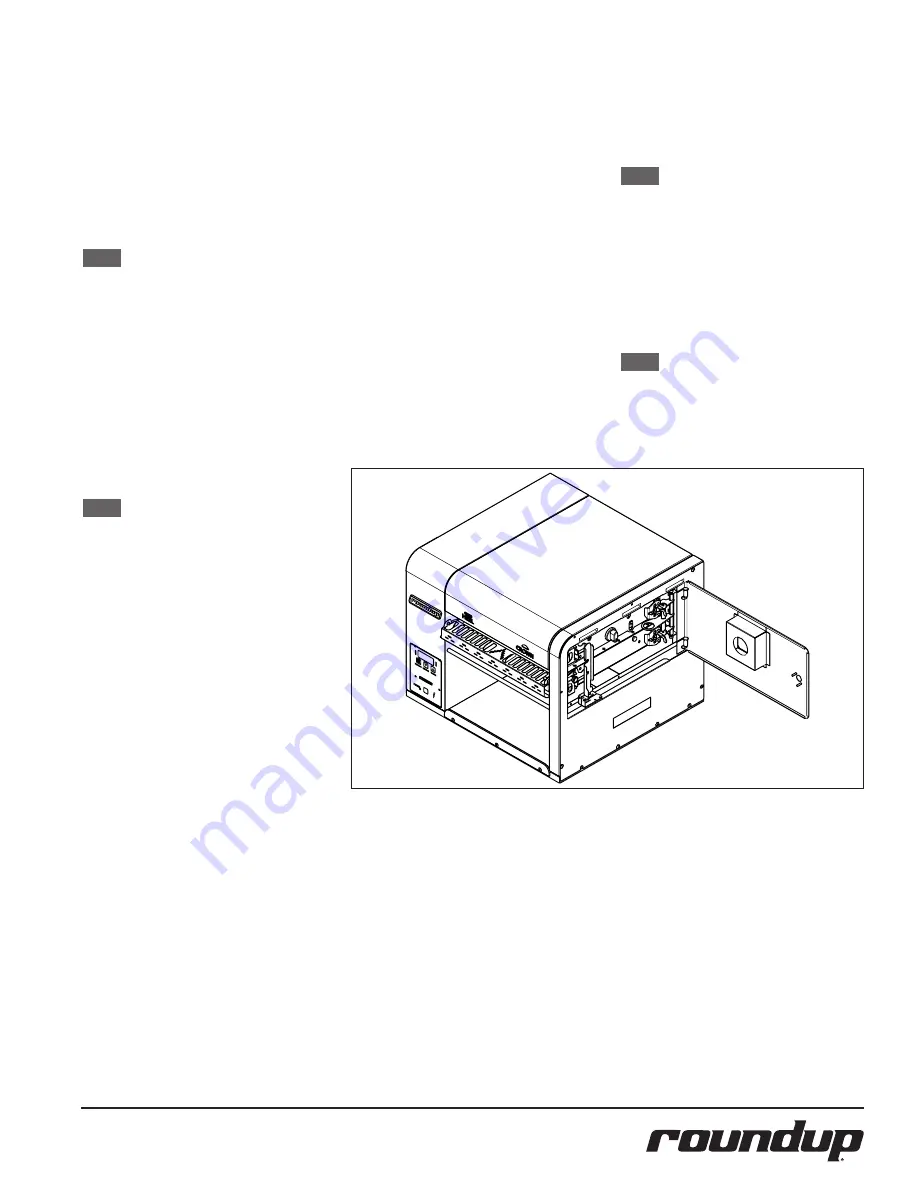

3. Open the side door (Figure 1) and

remove all of the plastic ties secur-

ing the toaster mechanism.

4. Remove all packing materials and

protective coverings from the unit.

5. Wipe the entire exterior of the

toaster and the accessories men-

tioned above with a hot damp

cloth. Allow to air dry

NOTE:

Do NOT use a dripping wet

cloth. Wring out before use.

6. Attach the Bun Chute, Bun Feeder,

and Butter Wheel assembly.

7. Make sure the Compression Knob

is set to 3, the default setting.

When placing the toaster into service,

pay attention to the following guidelines.

y

The power cord is located at the

bottom of the unit. The unit is

designed to be placed on a table

that will NOT pinch the power cord.

y

Make sure the power switch is off

and the unit is at room temperature

before plugging in the power cord.

y

Do not block or cover any

openings on the unit.

y

Do not immerse the power

cord or plug in water.

y

Keep the power cord away

from heated surfaces.

y

Do not allow the power cord to

hang over edge of table or counter.

y

Place the unit on a sturdy, level

table or other work surface.

y

Turn the power switch to

off (if it is set to on).

y

Ensure the line voltage cor-

responds to the stated voltage

on the specification label and

power cord warning tag.

8. Plug the power cord into the ap-

propriate power outlet. Refer to the

specification plate for the proper

voltage.

Figure 1.

OPERATION

1. Press and release the Power button

to turn the toaster on. Allow the

toaster to warm up until USE ap-

pears in the display

2. Set the Compression Knobs to the

desired setting. The recommended

Compression Settings are:

CROWN - #4

HEEL - #3

3. Insert product into the appropriate

lane on the Bun Feeder according

to Bun Feeder labels. Insert buns

with the cut side facing down.

4. Finished product drops into the bun

landing zone.

Light/Dark Adjustments

The light/dark value can be adjusted when

the unit is displaying “USE”. To adjust the

light/dark value, press the LIGHTER or

DARKER button. The display will change to

show the current light/dark value.

NOTE:

The default light/dark value is

d0.

Press the LIGHTER or DARKER buttons to

change the light/dark value. The adjust-

ment range is L1-L9 and d0-d9. L9 is the

lightest, d0 is the middle, and d9 is the

darkest setting.

To save the light/dark value, press the PRO-

GRAM button or wait 5 seconds until the

screen displays “USE”.

NOTE:

Adjusting the light/dark value

does NOT change the tempera-

ture. It changes the speed of the

conveyors. The light/dark value

will reset to the default value of

d0 when the unit is turned off.