- 7 -

www.rotork.com www.remotecontrol.se

Electrical wiring

1. Remove the ACTUATOR cover by loosening the four

captive cover bolts.

2. Confirm that the wiring diagram located in the

ACTUATOR and the wiring number on the nameplate

match with each other.

3. Confirm that the main power and supply described on

the nameplate of the ACTUATOR match with each other.

The two conduit entries on the SA-Series ACTUATOR

are PF1/2”. The ACTUATOR is sold worldwide, so there

maybe some differences as to the thread and pitch

standards. Check with your supplier to confirm which

standard is supplied in your area.

Wire Connection

Korea, Japan, China

PF 1/2”

Europe, UK, Australia, NZ

M20

US, Canada

NPT 1/2”

1. Standard conduit and conduit seal fittings may be used

when installing and wiring the ACTUATOR.

To prevent moisture and humidity from entering the

ACTUATOR, it is highly recommended that a seal fitting

be installed in the ACTUATOR conduit entry.

After all the conduit and wiring has been completed, then

the seal fitting can be sealed with packing and or a

potting material.

2. Any unused conduit entry must remain plugged with the

pipe plug provided with the ACTUATOR.

Do not remove the remaining plug as it is already sealed.

Main Power must only be applied when the top

cover is re-installed on the actuator body. If the

main power is on while wiring the actuator stop

work immediately and turn the power off. Only

then it is safe to proceed.

6. Be sure to wire and energize the heater as shown in

the wiring diagram.

7. Each ACTUATOR must be powered by their own

individual relays to prevent voltage feedback and

ACTUATOR damage.

8. After the wiring is completed in the ACTUATOR, use

wire ties to group the wires together and clean up

their appearance. Be certain that the wires are secure

and away from any moving parts.

Remove any loose debris before replacing the cover.

9. When all the work is completed, replace the top cover

and secure it using the four cover screws.

10. Apply power and do a final check to confirm proper

operation.

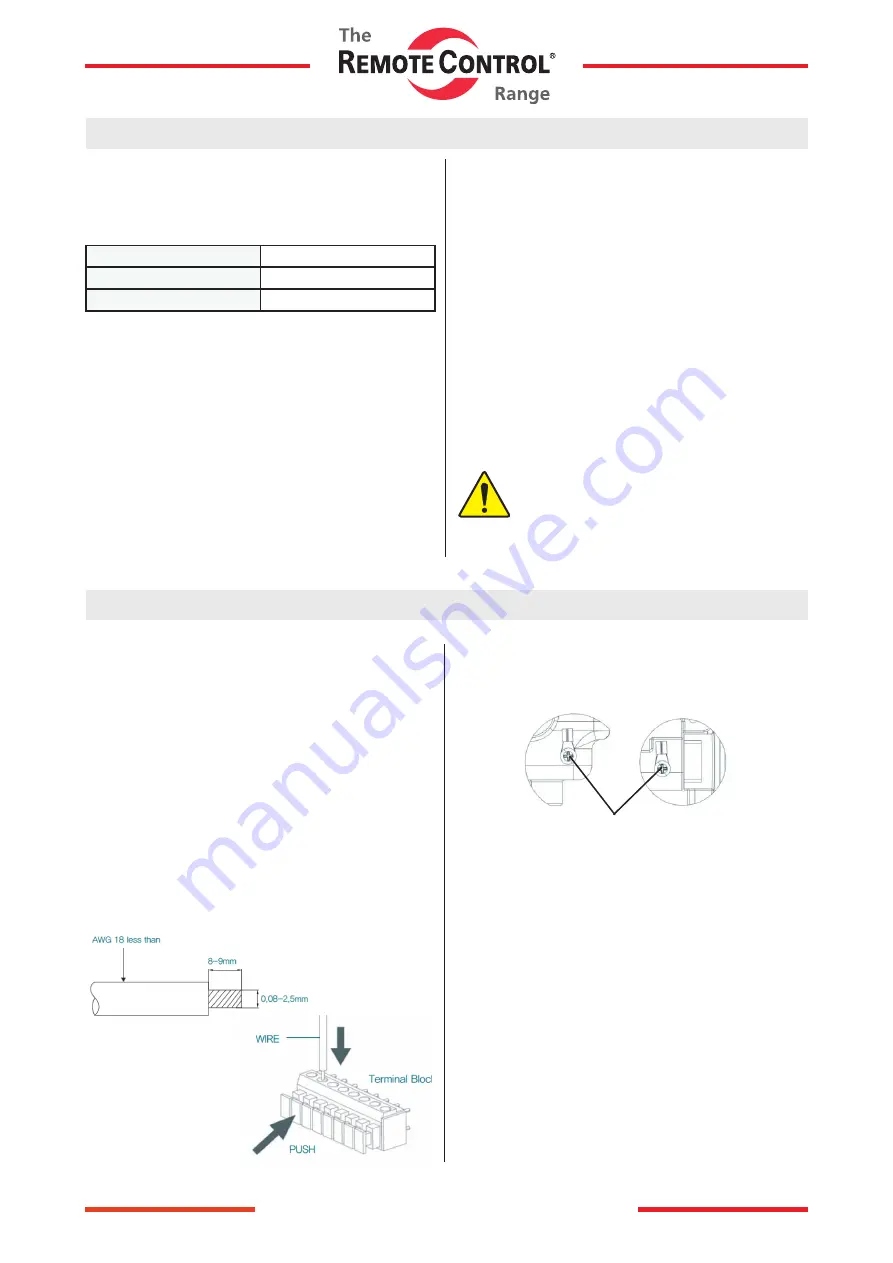

Interior/Exterior earth / ground terminal

4. Connect the wire to the terminal strip according to the

wiring diagram provided.

The SA- Series ACTUATOR uses the push type WAGO

brand terminal strip.

The push type strip makes wiring connections easy and

also helps to protect against pipeline vibration.

5. Be sure to properly ground the ACTUATOR by using the

grounding lugs provided on the inside and outside of the

ACTUATOR body.