12

Ronk Vigilant

®

Owner’s and Installation Manual

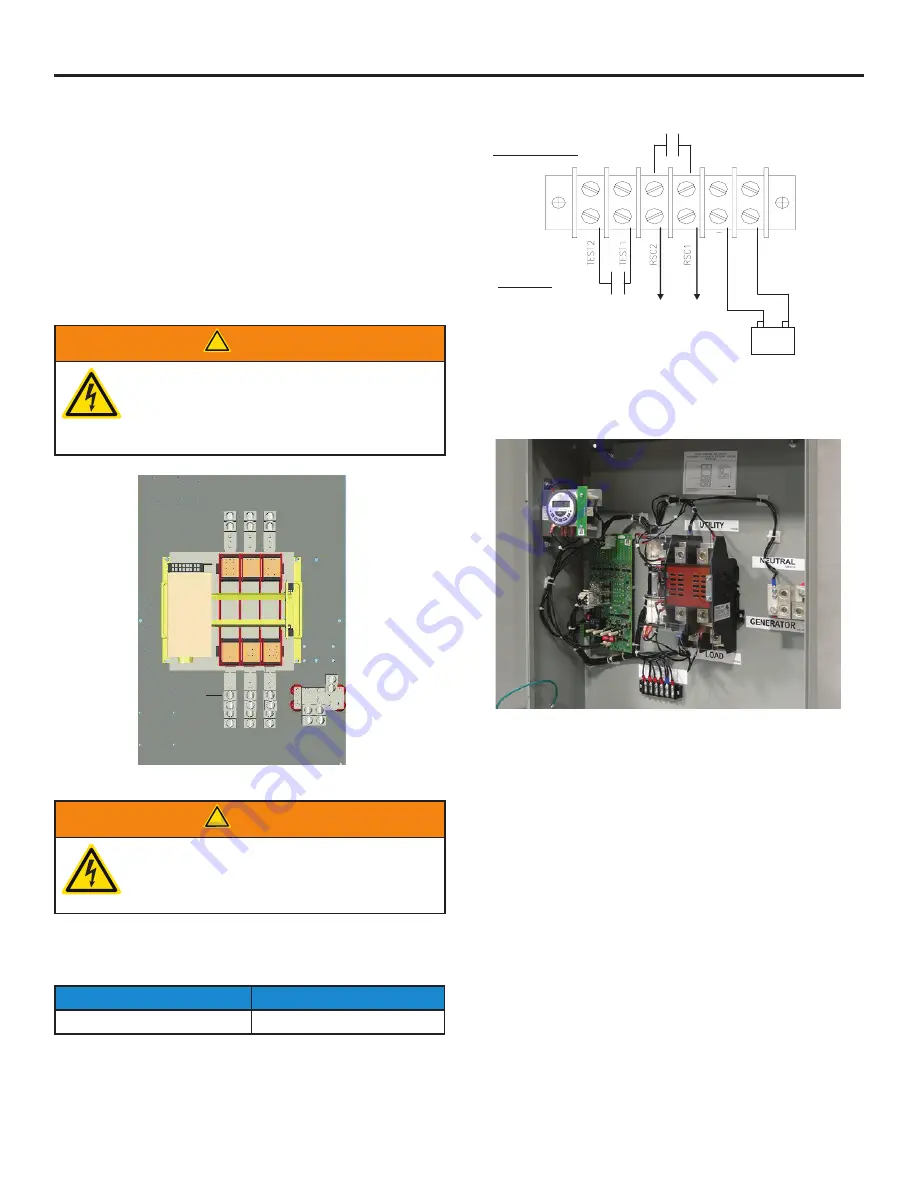

INSTALLATION AND WIRING

Power Connections

Proper power cables need to be installed to the transfer switch and

should be installed by licensed electrical contractors. Improper instal-

lation or connections of these power cables are extremely dangerous

and may cause severe injury or death. All power connections are to

be connected to the proper lugs, which are included on the switch

contactor and neutral block assembly. Connect the utility, generator,

neutral and load cables to the terminals, which are clearly marked

on the transfer switch

(see Figure 5)

. Verify that all connections

are correct before tightening lugs. All power cable lug connections

must be tightened to the proper torque values as shown in

Table 1.

!

WARNING

Low-voltage wire cannot be installed in the same

conduit as power voltage wiring. It could result

in shock due to short circuit as well as cause

electromagnetic interference resulting in

non-operation of the system.

Utility Cable

Lugs

Generator

Cable Lugs

Load Cable

Lugs

Neutral

Lugs

Figure 4 – Power Cable Connection Locations

!

WARNING

On 600A models, always install the transparent

protective shields covering the power

connections of the switch mechanism once the

proper connections are performed.

Lug Torque Values

Table 1: 400-600A Lug Torque Values

Internal Socket Size Across Flats

Tightening Torque

1/2 in. (13 mm)

500 in-lb (56 N·m)

Wire size range 4 to 600 MCM copper using Ilsco lug # TA-500-S

for 400A systems

Wire size range 2 to 600 MCM copper using Ilsco lug # PB2-600

for 600A systems

Connections

Ba

tter

y

+

Ba

tter

y

-

Transfer Switch

(Internal)

Generator

SPST

(Optional)

12/24VDC

+

-

N.O. dry contacts

Remote Start

Contacts

–

To

Generator

Generator Battery

Figure 5

Figure 6

OTE:

N

The transfer switch consists of the 6-position terminal

block (shown in Figure 6) for connections.

B

and

Battery –

must be connected for operation of the

control board. The battery is either 12V DC or 24V DC. A 1A fuse

should be placed on the B connection. Do not use an

isolated power supply to power the controller as the controller

requires a reference to neutral for AC sensing, which it obtains

from the distribution system via Battery -.

RSC1

and

RSC2

need to be connected to the remote start/stop

connections of the generator to allow automatic starting. These

are N.O. dry contacts.

An optional customer-supplied test switch may be installed by the

customer using the

TEST 1

and

TEST 2

terminals. A closed circuit

between the test connections will simulate a utility failure. See

wiring diagram for details.

The battery charger needs to be of high quality. Low-quality

battery chargers will often go into full recharge mode due to

control board current draw. This will quickly wear out the battery.