•

Do not use a tool that is leaking air, with missing or damaged parts, or that requires repairs.

Verify that all screws are securely tightened.

•

For optimal safety and tool performance, inspect the tool before every usage in order to ensure free movement of

the trigger, safety mechanisms, and spring.

•

Keep the work area clean.

A cluttered or dirty workbench or floor are more prone to accidents. They should be kept clear and clean.

•

This tool is not a toy. Use it with caution.

•

Handling and storage of oil:

Use the tool with adequate ventilation. Avoid contact of oil with eyes, skin, and clothing. Avoid

breathing spray or mist. Store in a tightly closed container in a cool, dry, well-ventilated area free from incompatible substances.

•

Tripping hazard:

The air hose may become a tripping hazard when it is placed in the work area.

•

Do not store the tool in a freezing environment

to prevent ice formation on the operating valves of the

tool, as doing so may cause tool failure.

•

Disconnect the tool from the air supply before loading or changing nails

in order to prevent a nail from

being fired during loading. Failure to comply may result in injury or damage to equipment.

•

Use safety goggles and ear protection:

Wear safety glasses with side shields when operating the tool and verify that others in the work area are also

wearing safety glasses. Safety glasses must provide protection from flying particles from the front and the sides.

Air-powered tools are loud and the sound can cause hearing damage. Always wear ear protection to prevent

hearing damage and loss. Failure to comply may result in injury.

Do not use while under the influence of alcohol, drugs or medication.

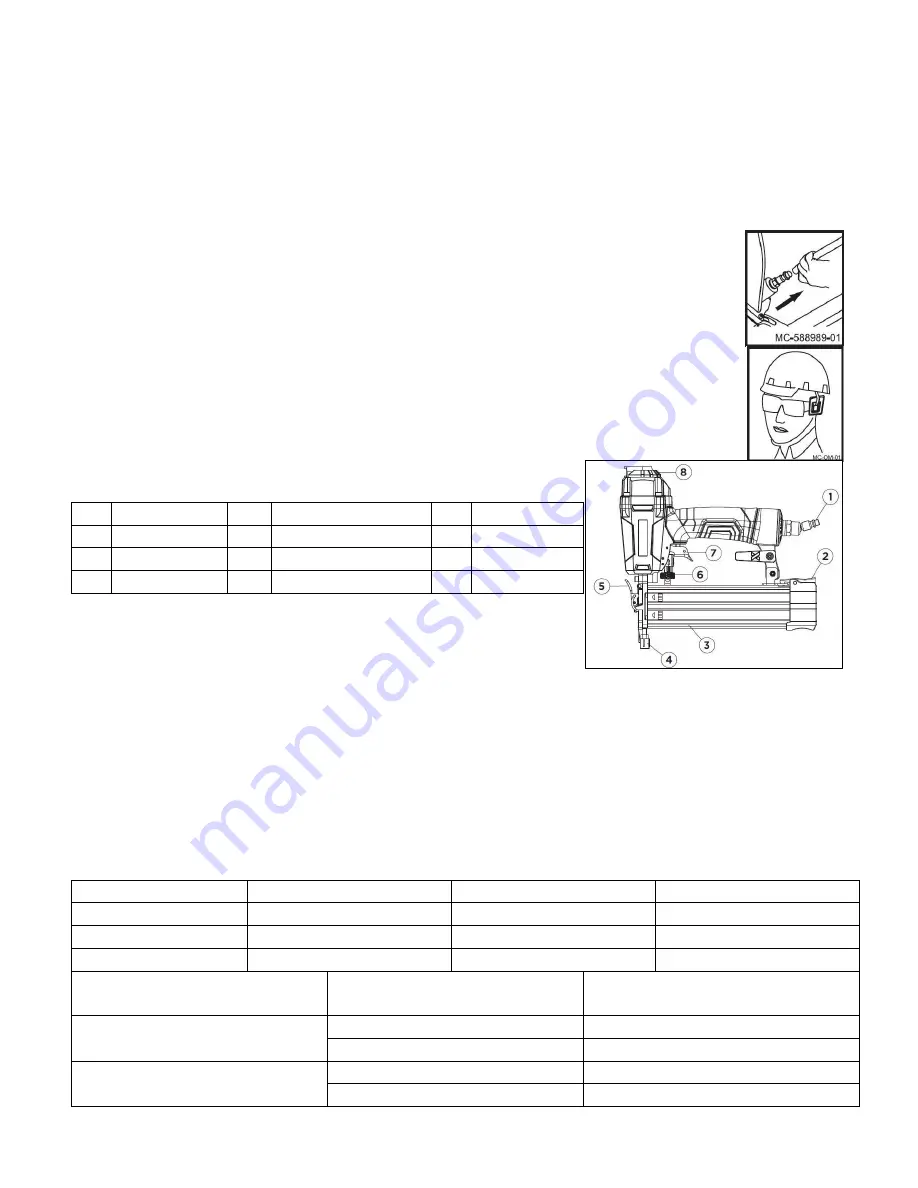

KEY PARTS DIAGRAM

No.

Description

No.

Description

No.

Description

1

Air inlet plug

4

Safety tip

7

Trigger

2

Magazine latch

5

Quick release handle

8

Air deflector

3

Magazine

6

Depth adjustment dial

TECHNICAL INFORMATION

Compatible compressors

GUIDELINES FOR PROPER USE AND OPERATION

Be sure to use a proper air compressor with RONGPENG

Air-powered tools. The compressor that is being used must be able to supply

appropriate amount of pressure (PSI) to the tool.

General use

This RONGPENG

Air-powered Brad Nailer

includes a die cast aluminum body that is strong and lightweight, and a comfort grip rubber handle for

improved control and comfort, even during extended use. The tool has a magazine that accepts 18-gauge and 5/8 - 2" (15 to 50 mm) long brad nails,

without adjustment. A hardened one-piece drive blade is provided for professional application, and an adjusting wheel for controlling the depth of the nails.

A touch-strike security system is included to ensure the safety of the operator. The tool features a 360 air deflector that is adjustable in any direction, and

a quick-release handle for clearing jams. The Air-powered Brad Nailer is best suited for installing door and window trim, decorative trim, cabinet work,

finish paneling, framing, scribe molding, upholstery, beading, chair rail, flooring works, etc.

Air Compressor Size and Power

1/3–1 1/3 HP

1 1/2–2 HP

3+ HP

2–6 Gallons

Light-duty and intermittent use

Light-duty and intermittent use

Light-duty and intermittent use

8–11 Gallons

Light-duty and intermittent use Heavy-duty and continuous use

Heavy-duty and continuous use

15+ Gallons

Medium-duty and intermittent use

Heavy-duty and continuous use

Heavy-duty and continuous use

Wood Density Nail Size Compressor Air

Pressure

Wood Density Nail Size Compressor Air

Pressure

Wood Density Nail Size Compressor Air

Pressure

>0.6 g/cm3

<1 1/2" (32 mm)

90psi(6.2bar)

brad nails

110psi(7.6bar)

≤0.6 g/cm3

≥

1 1/2" (32 mm)

70psi(4.8bar)

brad nails

90psi(6.2bar)