5

012208

5.0 INSTALLATION AND ELECTRICAL

CONNECTION—GENERAL

All equipment manufactured by Ronan Engineering is

carefully packaged and shipped to prevent damage. Any

discrepancies between shipping contents and invoice

should be immediately reported to Ronan or the Ronan

representative.

All Series X90 system components (source holder,

integral switch and remote tube assembly) will tolerate

normal industrial vibration. However, in cases where

vibrators are attached directly to the vessel, the system

components must be mounted on adjacent building

framework or use special supports that provide a degree

of isolation.

When the axis of the detector is placed parallel to the

surface of the process material and its side-facing

source, relay contact changeover will be obtained when

the set limit is exceeded by about one-half inch. When a

level limit is appropriate, a broad band of about five

inches can be obtained by placing the detector axis

perpendicular to the surface of the process material. In

either case, an alarm is produced after the tube is

obscured from (or exposed to) the radiation from the

source.

Whenever possible, separate power sources should be

used for the X90 and the alarm circuit. With this

arrangement, the alarm will operate if the power to the

X90 is interrupted (provided, of course, the alarm circuit

has power available).

Local electrical codes must be followed for all wiring. All

conduit entrances should be sealed to prevent

condensed moisture or water from entering the

enclosures. The cable used to connect the remote

detector should also be run through conduit. All

explosion-proof housing covers must be replaced when

the system is in operation.

6.0 SETUP

Normal setup by the user involves setting two (2) jumper

Options on the switch. The first is the High/Low Level

Alarm. The second is the Buildup Alarm enable. The

jumper must be set to

Enabled

or

Disabled

depending

upon the application. Note that if the jumper for Alarm is

set to Low Level Alarm, the Buildup Alarm will be

disabled regardless of the jumper setting. The standard

(or custom) parameters will already have been

programmed into the unit at the factory. The user must

then mount and wire to the switch. Once a reference is

performed, the switch is ready to use.

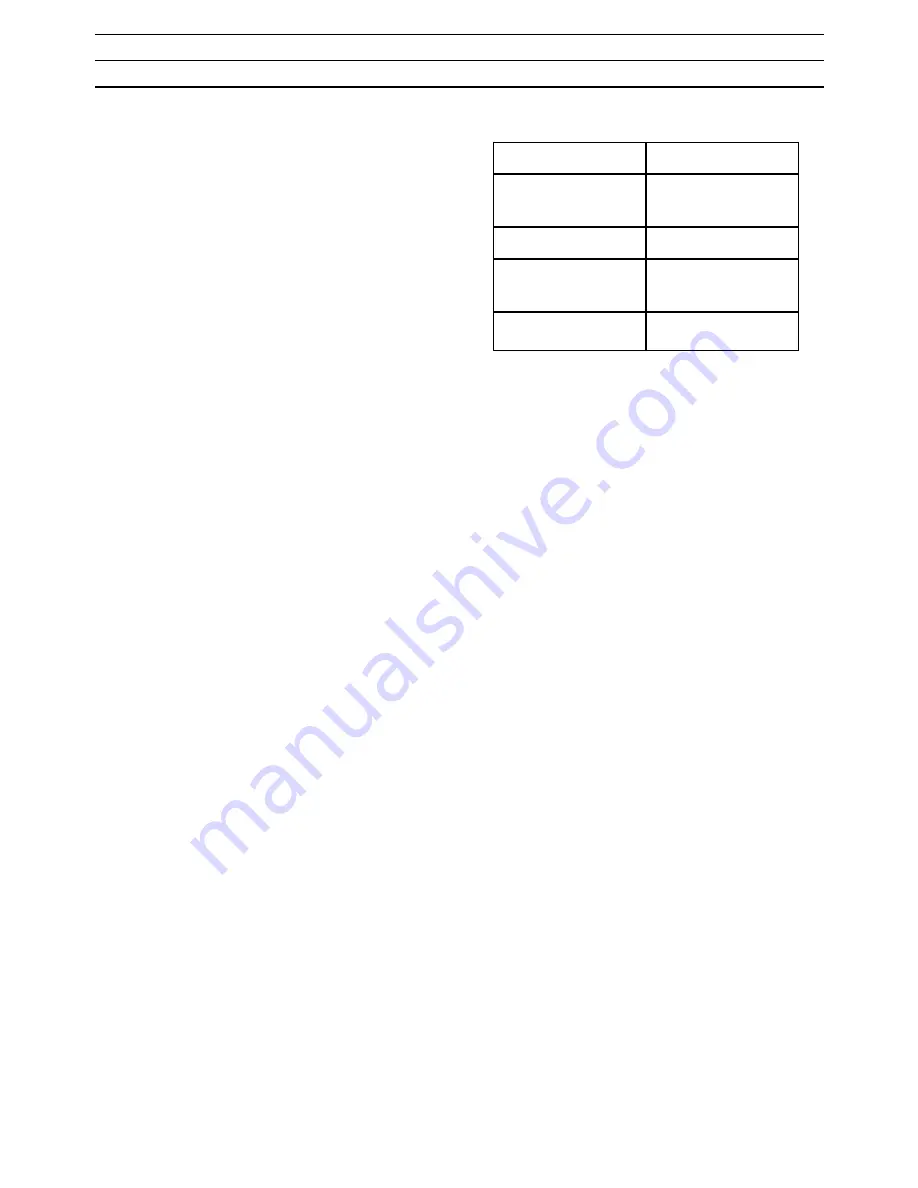

The on board dip switch settings are defined as follows:

7.0 CALIBRATION CONTROLS

The following front-panel controls are used in the set-

up procedures :

Start Reference Push Button

is pushed to start the

referencing of the switch on an empty vessel.

Reference in Process LED

indicates a referencing is

occurring.

Normal LED

indicates the switch is in normal opera-

tion.

Fail Alarm LED

indicates any equipment problems.

Level Alarm LED

indicates process alarm states.

Push to Test Button

is used to test hardware.

Communication Port is used to

connect hand held

programmer for detail setup (optional).

Calibration should be attempted only after all system

components have been securely mounted in position

with power and other connections made where re-

quired.

7.1 Referencing

A local or remote pushbutton can be used to refer-

ence the switch. The remote

Reference

pushbutton

can be mounted up to 1000 feet away from the

switch. When the

Reference

input is held for 5 sec-

onds, the

Reference LED

will indicate that the

Refer-

encing

is in process. Once the

Reference

has been

completed, the

Reference LED

will be extinguished.

If a detector failure occurs during referencing, the

Reference LED

will flash rapidly for 5 seconds to indi-

cate the condition.

7.2 Push-to-Test Function

A second pushbutton (local only) is available as a

Push-to-Test Function. This pushbutton will “short

Switch Position

Function

1-5

Device Address (0-31) for

multi-drop communications

access.

6

Not Used

7

Level Alarm Mode:

On=High Level/Off= Low

Level Alarm

8

Buildup alarm Mode: On=

Enabled/Off=Disabled