The Air Driven Sewer Pipe Tapping Machine is powered by a 1.75 horsepower motor. Operation is as simple

as attaching the air hose from your compressor or other source to the end of the trigger handle. Care should be

taken to ensure the holesaw and pilot bit have been properly connected before attaching the Sewer Pipe Tap-

ping Machine to a power source.

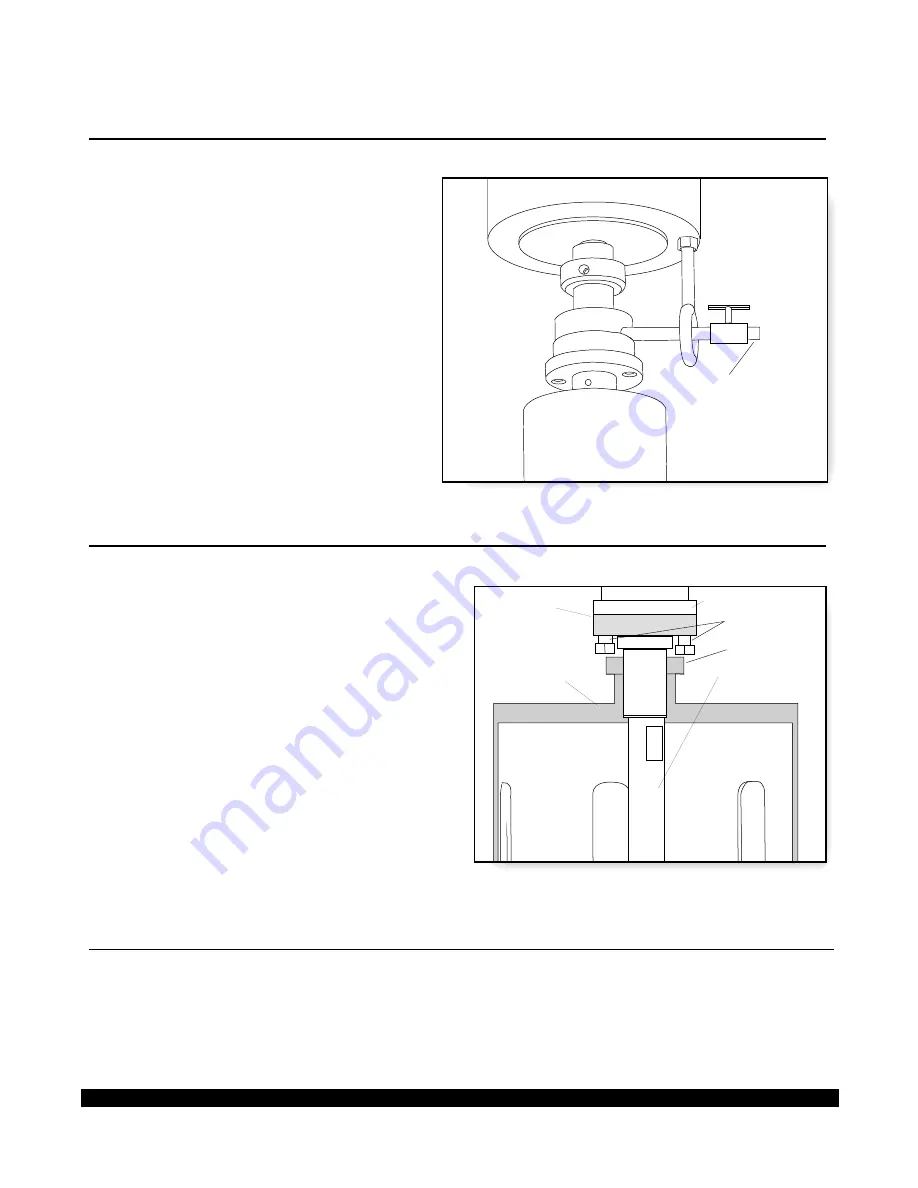

INSTALLING PVC ADAPTER, PVC PILOT & PVC HOLESAW

The PVC adapter, which mates the PVC pilot and

PVC holesaw to the Sewer Pipe Tapping Machine is

easily installed by inserting the cutter screws up through

the 7/16” holes and threading them into the main swivel

housing. Next thread the PVC pilot into the end of the

PVC adapter and tighten. Thread the Jam Nut onto the

end of the PVC adapter until it bottoms out on the back

of the threads, then turn it back one to two turns. This

allows the Jam Nut to be backed away from the holesaw

when removing the holesaw after the cut.

CONNECTING THE AIR DRIVEN UNIT TO COMPRESSOR

CONNECTING THE PRESSURIZED WATER TANK

WATER TANK HAS TO

BE USED WHEN

CUTTING WITH

DIAMOND TIPPED

PILOTS AND

HOLESAWS. FLOW OF

WATER MUST BE

INTRODUCED HERE.

PVC Adapter

Main Swivel Housing

Cutter Bolts

Jam Nut

PVC Pilot

PVC Holesaw

Note: Water needs to be introduced to

the diamond tips when using the diamond

tipped pilot and diamond tipped holesaws.

Damage to the pilot bit and holesaw will re-

sult if water is not used while cutting.

Connect the water tank quick disconnect

to the nipple sticking out the side of the bear-

ing housing. Make sure the nipple is sticking

through the eye bolt thatʼs threaded into the

gearbox. Pressurize the water tank by using

the pump handle on the tank.