5

ECO-SOL MAX 3 Ink Switching Method

Switching the Ink

STEP 1: Updating the Printer Unit Firmware

Use the file that you have downloaded to update the firmware of the printer unit to a version that supports MAX 3 ink. For

the update method, refer to "readme.pdf," the file that you downloaded at the same time as the firmware.

STEP 2: Switching the Ink

1.

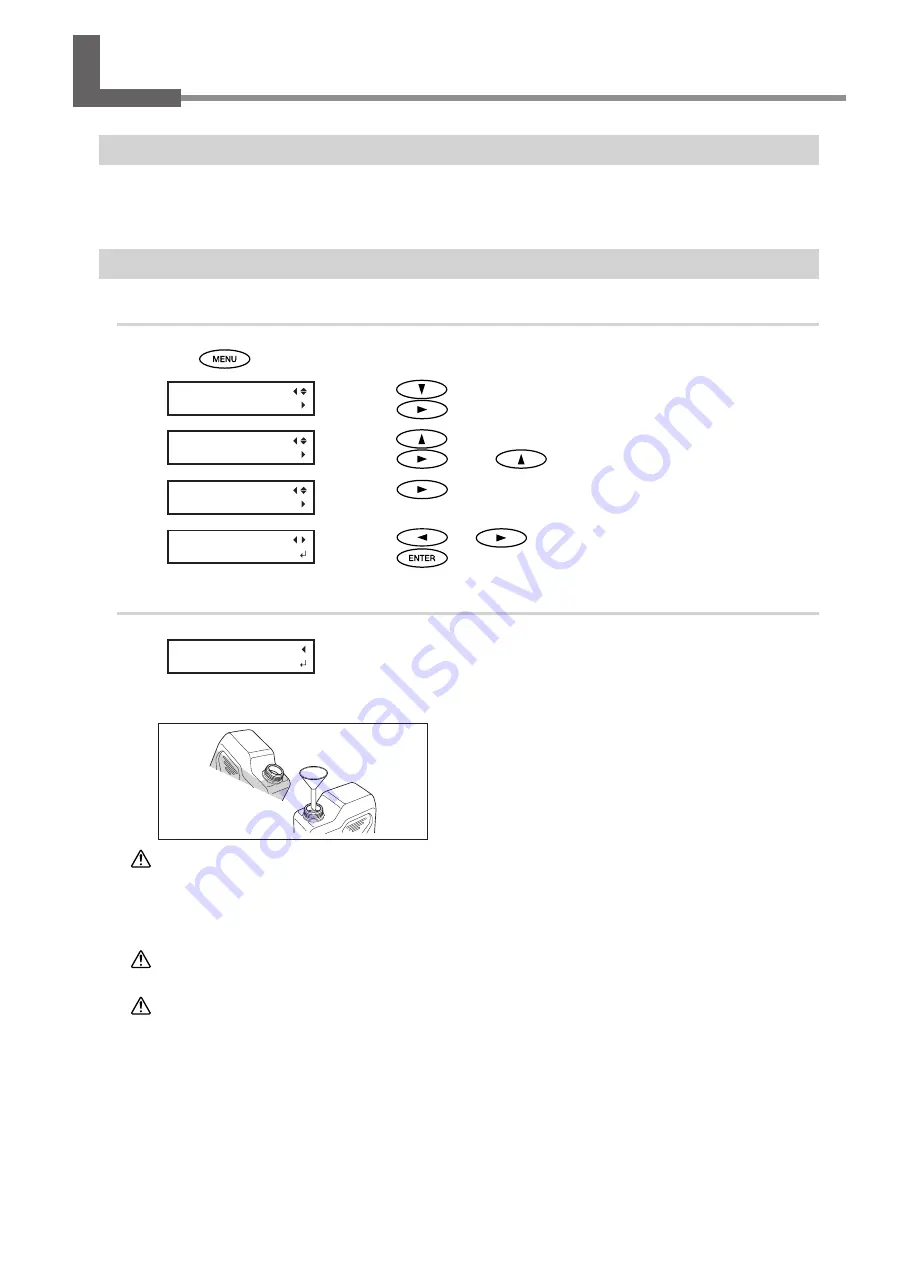

Display the [CHANGE INK SET] menu.

Press

.

Press

several times to display the screen shown on the left.

Press

.

Press

several times to display the screen shown on the left.

Press

, then

.

Press

.

Press

or

to select [YES].

Press

.

2.

Switch the ink cartridges.

When the screen on the left is displayed, remove the drain bottle and

discard the discharged fluid.

Use the included drain funnel to transfer the discharged fluid from the printer's drain

bottle to the included drain bottle.

CAUTION

Before you detach the drain bottle, be sure to wait for the screen to display "EMPTY

DRAIN BOTTLE." After discarding the discharged fluid, promptly attach the drain bottle

to the machine.

Failing to follow this procedure may cause discharged fluid to flow out of the machine and

spill, soiling your hands or the floor.

WARNING

Never place discharged fluid or ink near an open flame.

Doing so may cause a fire.

CAUTION

To store discharged fluid temporarily, place it in the included drain bottle or in a du

-

rable sealed container such as a metal can or polyethylene tank, and cap the container

tightly.

Any spillage or vapor leakage may cause a fire, an odor, or physical distress.

Dispose of discharged fluid properly, in accordance with the laws in effect in your locale.

Discharged fluid contains toxic ingredients. Never attempt to incinerate discharged fluid or discard it with ordinary trash.

Also, do not dispose of it in sewer systems, rivers, or streams. Doing so may have an adverse impact on the environment.

/'07

57$/'07

57$/'07

+0-%10641.

+0-%10641.

%*#0)'+0-5'6

%*#0)'+0-5'6!

=;'5?01

'/26;

&4#+0$166.'

Summary of Contents for VersaCAMM ECO-SOL MAX3

Page 21: ...R2 160408 FA01047...