23

Part Names

NOTICE

If you will leave the printing head being uncapped for a long time (for example, open the front cover while

printing is made on the middle of platen), printing heads may get clogging and, in some case it results unrecov-

erable damage to the printing head.

When the carriage is stopped on the platen, press the [POWER] key to reset the power. The carriage moves and

the printing head is capped.

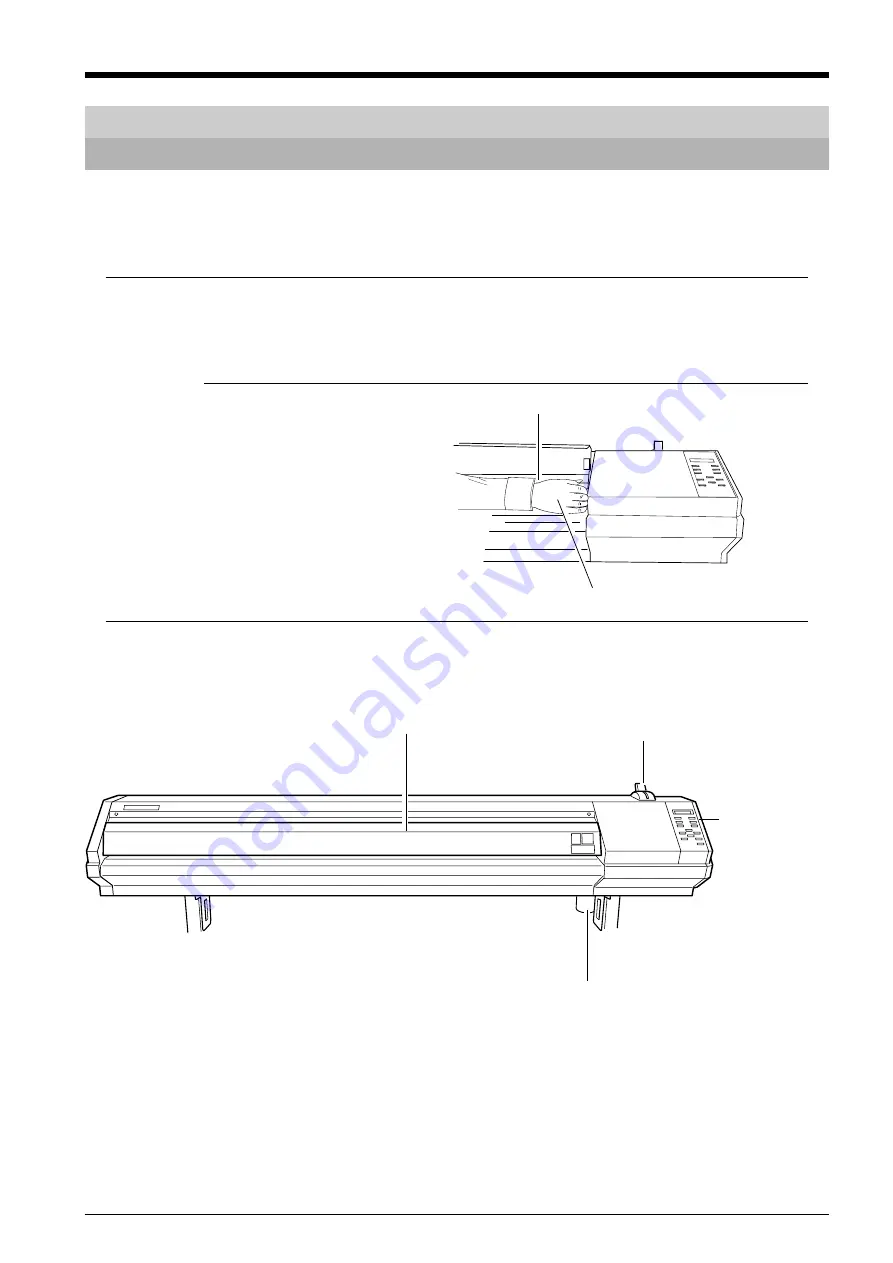

Front View

Sheet Loading Lever

Front cover

If the cover is opened while the printing, it will

execute an emergency stop.

Operation panel

Drain bottle

Do not touch the rail or place the hands

inside the right-hand cover.

Touching the area shown may cause the

fingers to be soiled by grease or ink, and

may result in diminished image quality.

Do not put hands inside

Part Names

Rail

Summary of Contents for SolJet SJ-500

Page 77: ...R1 020320...