9

INSTALLATION

(continued)

ELECTRICAL CONNECTIONS AND MOTOR WIRING:

1. ELECTRICAL WIRING SHOULD

ONLY

BE PERFORMED BY A QUALIFIED ELECTRICIAN, FAMILIAR WITH ALL APPLICABLE CODES.

2. NOTE ON COMPRESSORS THAT REQUIRE THE USE OF A MAGNETIC STARTER: The incoming power MUST be brought into the magnetic starter

(which is used to provide the motor with thermal overload protection)*. The power should NEVER be brought directly into the pressure switch.

3. NOTE ON START/STOP COMPRESSORS: Never shut off the compressor using a remotely wired stop switch, or the main breaker, unless there’s an

emergency. All start/stop compressors must be manually stopped using the on/off lever on the pressure switch, or allowed to complete a full cycle,

in order to properly purge the line pressure and provide the motor with a

No Load

restart. If your compressor is set up to operate continuously,

always drain the tank pressure completely (by opening the tank drain valve) before restarting.

Most stationary ROLAIR compressors are shipped without a power cord. All power cords attached to this machine must be properly

grounded and installed by a qualified electrician with knowledge of the National Electrical Code (N.E.C.), OSHA Code and/or any

local/state/provincial codes having precedence. Failure to abide by applicable electrical codes may result in personal injury or property damage.

The motor must always be protected by a starter with properly sized thermal overload(s). The starter should protect the motor from

overheating and burn-out due to an overload, low voltage or single phasing of a 3-phase circuit. Failure to install the proper starter and overloads

will void the motor manufacturer’s warranty. Follow the National Electric Code or local electric code in providing wiring, fusing and disconnect

switches.

Check the electrical supply for voltage, phase and frequency to see that they match the nameplate stampings on the motor, magnetic

starter, solenoids and other controls. Use electrical wires of adequate size to carry the full load current of the motor without excessive voltage

drop.

CAUTION: Do not use a generator as the power source. Air compressors use inductive motors that require 3-5 times the full-load amp draw to

properly start. Most generators will not provide the wattage needed to properly start this type of electric motor.

After the wiring is completed, momentarily start the motor to make certain that the compressor flywheel rotates in the same direction as

indicated by the direction arrow on the compressor flywheel.

CAUTION: An easy way to check for proper rotation is to place a piece of paper on the outside of the belt guard cover while the machine is

running. If the piece of paper is blown away, the rotation is incorrect. Consult a qualified electrician to correct the rotation. Improper rotation

will lead to overheating and oil blowing out of the crankcase breather.

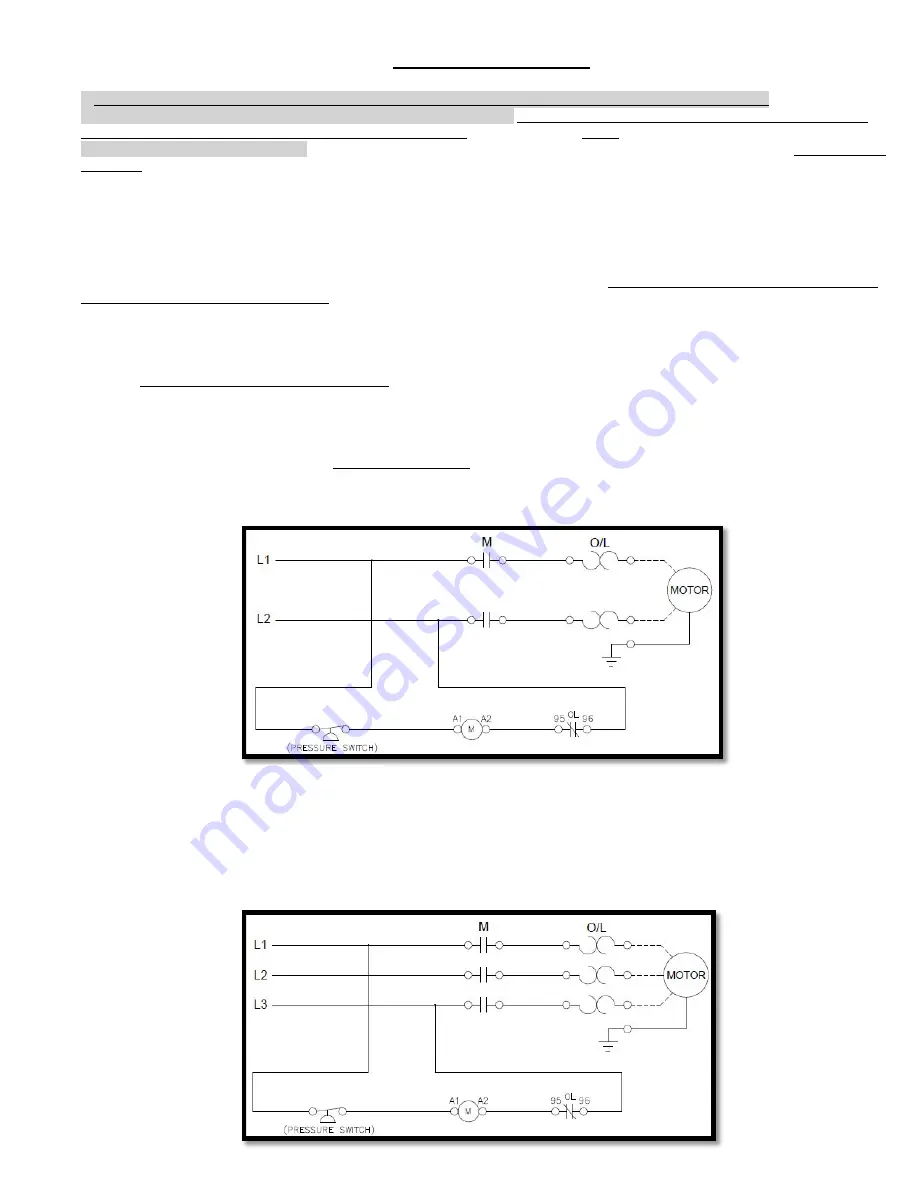

SINGLE PHASE:

NOTE: Constant speed units without a pressure switch require a jumper wire from 1L1 to A1

THREE PHASE: