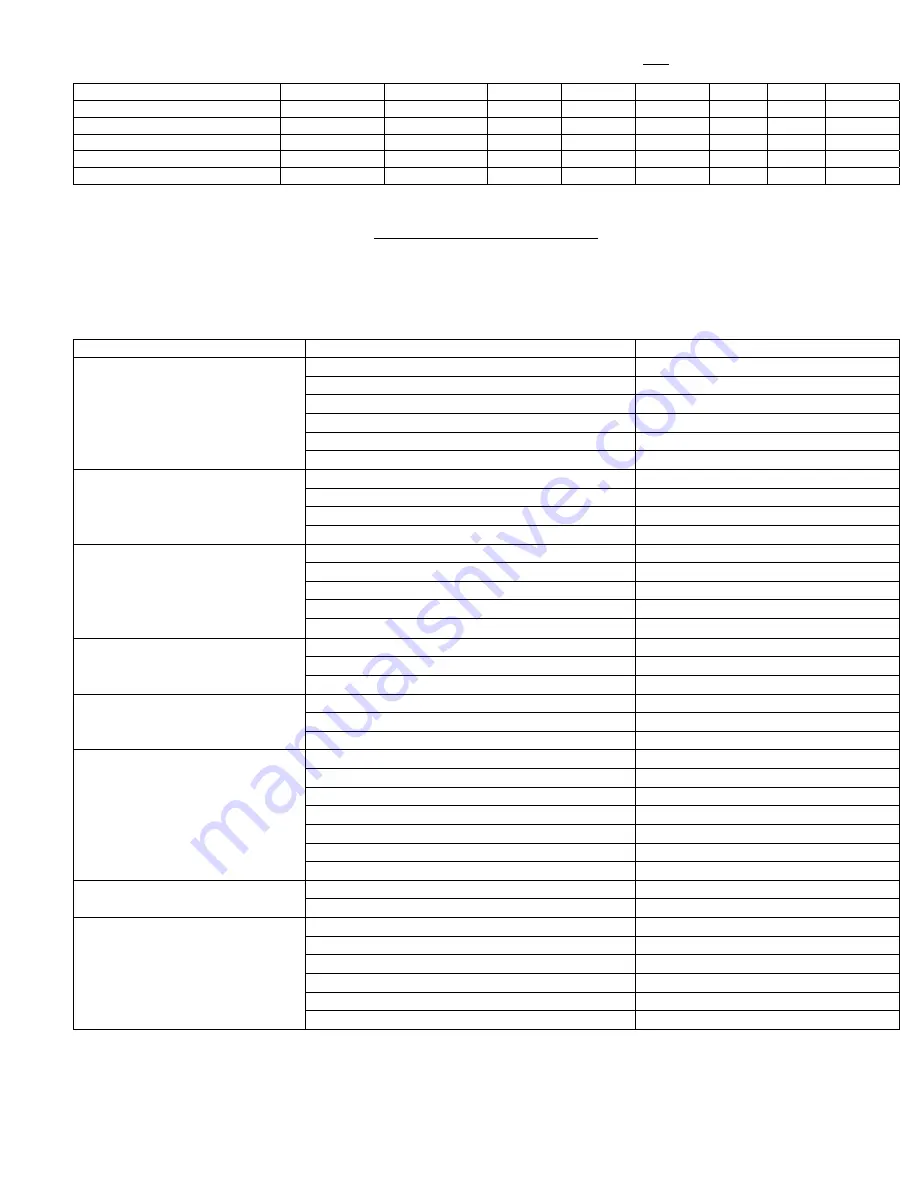

TORQUE CHART (INCH/LBS)

Determine pump type using suffix of model number (Example: V5180K30 uses a K30 pump.)

TROUBLESHOOTING

WARNING

-

Make sure you completely understand all of the safety warnings and operation of each system control

component before attempting any maintenance or repair. Always drain the tank pressure completely, make sure the

power cord is unplugged, and unit has time to cool before performing any maintenance or service operations.

PROBLEM

CAUSE

SOLUTION

Low discharge pressure

Air leaks

Correct air leaks

Restricted air intake

Clean or replace intake element

Loose/slipping belt(s)

Adjust belt tension

Compressor too small

Perform pump-up time test

Blown gasket

Replace head gaskets

Broken valves/worn rings

Replace valve/rings

Knocking

Loose pulley/flywheel

Tighten appropriate item

Loose belt(s)

Adjust belt tension

Lack of oil in crankcase

Add oil

Internal pump problem

Take pump in for service

Overheating

Poor ventilation

Relocate air compressor

Dirty cooling surfaces

Clean compressor

Incorrect flywheel rotation

Contact an electrician

Blown gasket(s)

Replace head gaskets

Broken valves

Replace valve/head gaskets

Excessive starting/stopping

Excessive air leaks

Correct air leaks

Unit too small for application

Add/replace air compressor

Air storage capacity too small

Add reserve air tank

Excessive belt wear

Motor pulley or flywheel out of alignment

Reposition pulley or flywheel

Flywheel/pulley wobble

Replace appropriate item

Improper belt tension

Adjust belt tension

Oil in discharge air or

oil blowing out of

crankcase vent

Wrong oil viscosity

Use correct type of oil

Improper flywheel rotation

Contact an electrician

Crankcase overfilled

Drain to proper oil level

Obstructed crankcase breather

Clean or replace breather

Inadequate ventilation

Relocate compressor

Restricted air intake

Clean or replace intake element

Worn piston rings

Take pump in for service

Water in crankcase

(Oil appears milky in color)

Infrequent cycling

Install crankcase heater

Incorrect or inferior oil

Use correct type of oil

Motor/compressor fails

to attain speed

Loose belts

Correct belt tension

Low voltage

Contact an electrician

Improper wiring

Contact an electrician or factory

Defective check valve

Replace check valve

Motor overload

Push motor reset

Inoperable relief valve

Replace pressure switch

NOTE: Reciprocating compressors consume a certain amount of oil under normal operation. If you are concerned

about your oil consumption, monitor and record oil consumption daily before consulting your dealer. When oil

consumption is normal and what appears to be milky oil is found in your lines, this is caused by small particles of oil,

along with water vapor, condensing in your air lines. To eliminate this problem: Air-Cooled Aftercoolers, Refrigerated

Dryers

and

Filters

are

available

through

your

dealer.

Pump Type

K17/K18

K24/K25

K28

K30

K35

K50

K60

K100

Head Bolts

243

243

347

347

347

694

347

694

Cylinder Bolts

182

182

330

330

330

521

330

521

Bearing Carrier Bolts

130

130

130

130

130

165

165

165

Connecting Rod Bolts

121.5

121.5

121.5

173.6

173.6 217

217

199.7

Flywheel 382

382

477

477

477

607

607

694