6

Fig. 8

Fig. 6

Fig. 7

5.

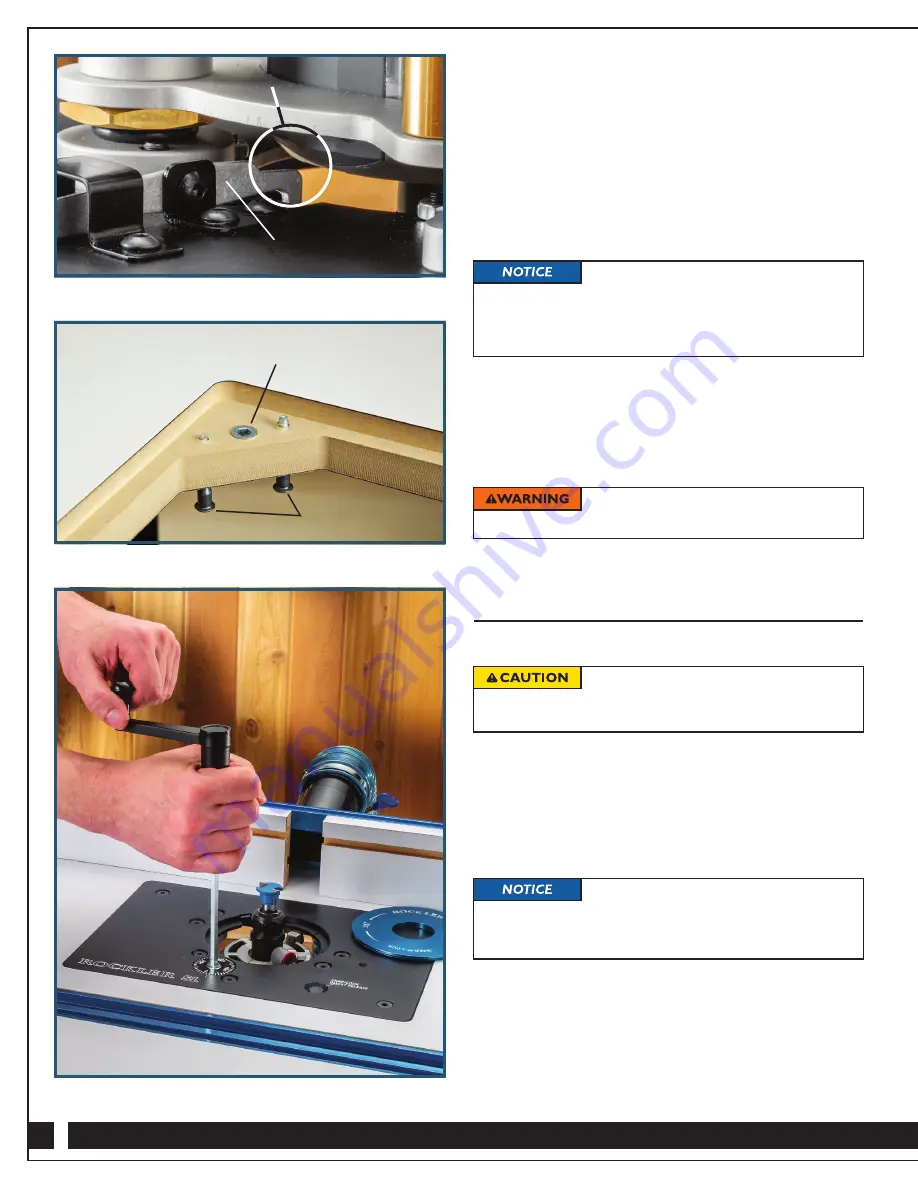

Slide the motor into the lift carriage, stopping 1/8" before the

motor contacts the Insert Ring release arm.

Fig. 6.

If your

router has a height adjustment rack on the outside of the

motor housing, be sure to orient the router so the rack fits

in the opening in the carriage. If possible, rotate the motor so

that the on/off switch and variable speed controls will be easily

accessible to you when the lift is installed in your router table.

6.

Once your router is positioned in the carriage, make sure

you’ve maintained the clearance between the motor housing

and the Insert Ring release arm and tighten the socket-head

adjustment screw until the router cannot shift or slide. Then

tighten the locking nuts.

7.

Fit the SL Router Lift in the center opening of your router

table. It is sized to fit the 8

1

⁄

4

" x 11

3

⁄

4

" openings of Rockler and

Bench Dog router tables. Use the leveling screws that came

with your router table to bring the plate flush to the table on

all edges.

Fig. 7.

Then secure the lift to the table by using

the included M4 hex wrench to install the two included

1/4"-20 plate-mounting screws.

8.

Before use, snap the Insert Ring back into the plate’s

center opening.

Installing/Changing Router Bits

1.

Press the Snap-Lock Insert Release Button to pop the

aluminum Snap-Lock Insert Ring off the plate.

2.

Insert the Crank Handle in the dial in the lift plate. Turn the

crank clockwise to raise the carriage until the router collet

is fully accessible.

Fig. 8.

3.

Use the wrench(es) that came with your router to loosen the

collet, if necessary, and insert the desired bit in the collet. Let

it bottom out; then lift it 1/16" before tightening the collet. This

is to help ensure the collet is gripping the full shank of the bit.

4.

Use the crank handle to lower the bit, and then snap the

Insert Ring back into place.

5.

When you’ve achieved the height desired, remove the handle

and place somewhere off the work surface for safety.

If you are installing the SL Router Lift in

a custom table application, you will have to fabricate the

correctly sized opening yourself. Rockler offers a separate

template (20956, sold separately) to make this operation

easier and more accurate.

To “zero-out” the Fine-Adjustment dial,

spin the thumbwheel until the “0” lines up with the engraved

line on the plate. The socket must not turn during this step.

Fig. 9.

To avoid serious injury, never attempt to

cut a workpiece without an Insert Ring installed.

Do

NOT

use a cordless drill to raise

and lower the lift carriage. The resulting friction will cause

premature wear to the threads.

Leveling screws on

your router table

Threaded insert to accept 1/4"-20

plate mounting screws

Maintain gap

Insert Ring release arm