11

Rockford Systems, LLC—www.rockfordsystems.com

Call: 1-800-922-7533

DM

2

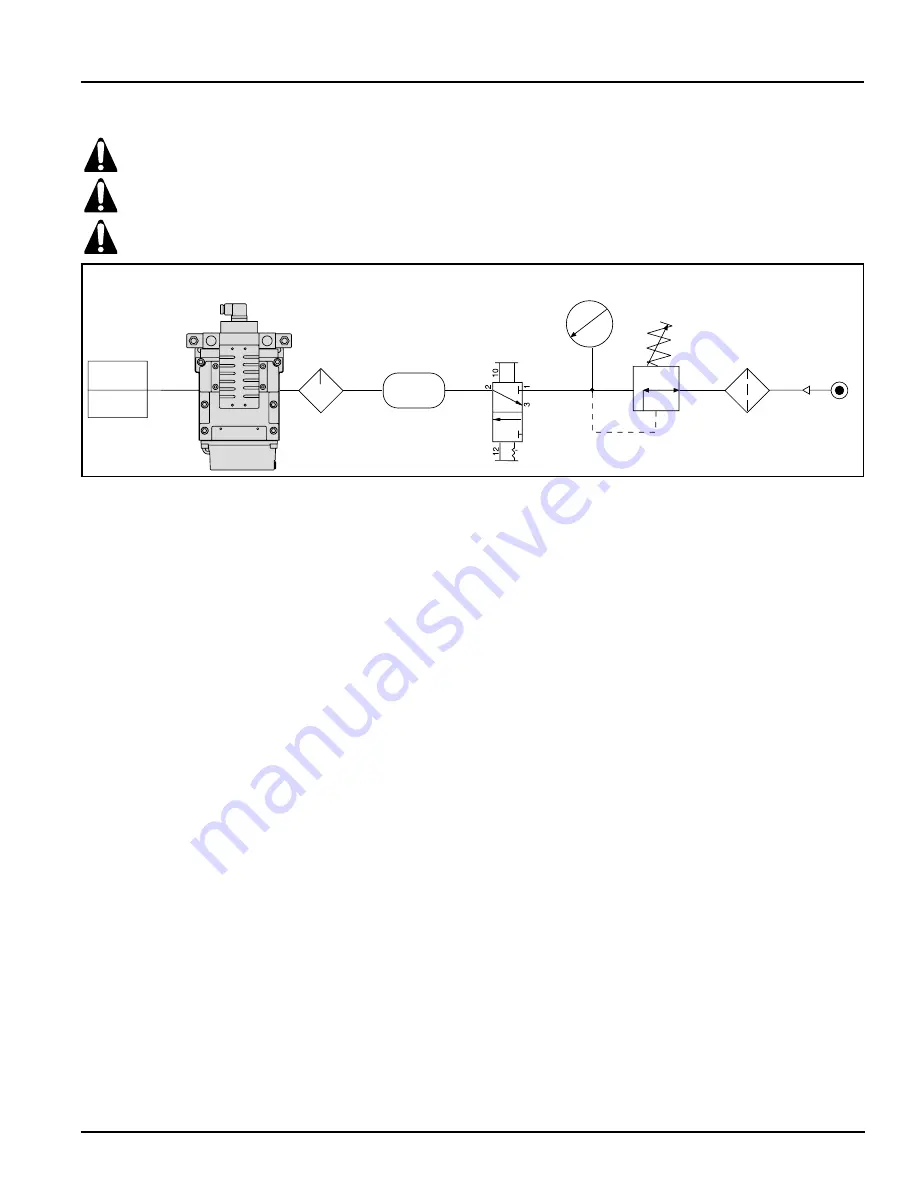

Series D Dual-Solenoid Valves

SECTION 5—INSTALLATION

Pressure Regulator

Clutch and

Brake

Combination

Filter and

Water Separator

Pressure Gauge

Volume

DM

2

Series D Duel-Solenoid Valve

(Status Indicator – Optional)

Lubricator

Lockout Valve

Air Lines—Before installing this valve in a new or existing sys-

tem, the air lines must be blown clean of all contaminants. It is

recommended that a 5-micron-rated air filter be installed in the

inlet line close to the valve.

Valve Inlet (Port 1)—Be sure that the supply line is of adequate

size and does not have any restrictions (e.g., a crimp in the line,

a sharp bend, or a clogged filter element). The air supply must

not only provide sufficient pressure (see standard specifica-

tions, page 8), but must also provide an adequate flow of air

on demand. Otherwise, the valve elements will be momentarily

starved for air and the valve may fail to operate.

Valve Outlet (Port 2)—For faster pressurizing and exhausting

of the mechanism being operated by the valve, locate the valve

as close as possible to the mechanism. The lines must be of

adequate size and be free of restrictions (e.g., a crimp in the line,

a sharp bend, or a clogged filter element).

Valve Exhaust (Port 3)—Do not restrict the air flow from the ex-

haust port as this can adversely affect the operation of the valve.

The valves are factory equipped with a properly sized muffler.

Only the muffler furnished should be used.

Reset Port (RESET)—If your valve is not equipped with a reset

solenoid on the valve, then the RESET port should be supplied,

externally, from a 3/2 normally closed valve. The lines must be

of adequate size and be free of restrictions (e.g., a crimp in the

line, a sharp bend, or a clogged filter element). Reset signals

must be momentary.

Electrical Supply—DM

2

Series D dual-solenoid valves get elec-

trical power through plug-in connectors. The electrical supply

must correspond to the voltage and Hertz ratings of the sole-

noids. Otherwise, the solenoids are subject to early failure. If

power is supplied by a transformer, it must be capable of han-

dling the inrush current without significant voltage drop. See

standard specifications on page 8 for inrush current data.

Operating Pressures and Temperatures—Allowable ranges

for pressure and temperatures are given in the standard specifi-

cations on page 8. Exceeding these values can adversely affect

performance and shorten valve life.

Pipe Installation—To install pipe in base ports, engage the pipe by

one turn, then apply pipe thread sealant (tape not recommended),

and tighten pipe. This procedure will prevent sealant from entering

and contaminating the valve. To install pipe with parallel threads

(e.g., SAE, ISO 228-G, etc.) do not use sealant. After installing pipe

into the base ports, use compressed air to blow any debris out of

the piping, then install the valve onto the base.

Test—Always perform a test procedure after installation

and/or repair prior to normal use. Observe normal press op-

eration safety precautions during these tests to avoid personal

injury or damage to equipment. Note: Reset may need to be

performed prior to beginning the test procedure. Also, both

pilot solenoids must be de-energized prior to reset and must

remain de-energized until after the reset signal is removed.

Test Procedure—

1 . Electrically energize both pilot solenoids simultaneously,

then de-energize one pilot solenoid. This should result in a

valve lockout and prevent the valve from operating.

2 . Energize both solenoids and the valve should remain in the

lockout condition.

3 . De-energize both pilot solenoids and reset the valve.

4 . Electrically energize both pilot solenoids simultaneously

again. De-energize the other pilot solenoid this time. Again,

this should result in a lockout.

5 . Energize both pilot solenoids. The valve should remain in a

lockout condition.

6 . De-energize both pilot solenoids and then reset the valve.

After satisfying these tests, energizing both pilot solenoids si-

multaneously should result in normal operation.

Fault Indication—If fault indication is desired, Rockford Systems,

LLC offers a status indicator option that can be used to signal to

the press controls that a fault has occurred. The status indicator uti-

lizes a pressure switch. The pressure switch has four electrical con-

tacts. During normal operation, the pressure switch is pressurized.

A lockout condition depressurizes the switch until the valve is re-

set. Contacts 1 and 2 are closed when the switch is depressur-

ized (normally closed) and contacts 1 and 3 are closed when an

adequate pressure signal is applied to the switch (normally open).

Please read and make sure you understand all installation instructions before proceeding with the installation.

INSTALLATION CONSIDERATIONS

Pneumatic equipment should be installed only by persons trained and experienced in such installation.

The exhaust air muffler must be kept clean at all times. Never operate the machine unless the muffler is clean. The

muffler must be cleaned on a regular basis.