Robotiq CN C M achine Tending Kit Instruction M anual

1.1.3. Setup and control

Hand-E is powered and controlled directly via a single device cable that carries a 24V DC supply and Modbus RTU communication

over RS-485. See the Installation for wiring information and section Control for controlling the gripper (software packages are available

for control via some types of robot controllers).

A gripper coupling is required to use Hand-E; providing mechanical and electrical connectivity. See the Installation to install the

coupling, the Technical dimensions for technical drawings, and the Spare Parts, Kits and Accessories for a list of available couplings.

Hand-E has an embedded object detection feature based on indirect sensing methods. When picking an object with the " go to"

command, the gripper status indicates whether or not an object has been picked, using only an object detection bit (0 or 1). When an

object is detected, the gripper no longer increases the force exerted on the object. If the object is being dropped, the gripper

automatically exerts more force until the object is detected or until the position target from the " go to command" is reached. For

details on object detection, see section Control.

1.2. Custom Fingers

The CNC Machine Tending Kit makes your grippers even more versatile than before. With the Fingertips Extender, you can widen the

grip to grasp larger objects. The 2F-85 Fingertips Conversion Kit kickstarts the tooling process of your own custom fingers by providing

an installation frame, or helps reusing legacy fingers for new applications. In addition, the CNC Machine Tending Kit is bundled with

three sets of Hand-E fingers, as well as V-groove fingertips (v4) manufactured for the2-Finger Adaptive Robot Gripper.

To mount a Fingertips Extender to a gripper rack or to mount fingers/ fingertips on the Fingertips Extender, see section Installation.

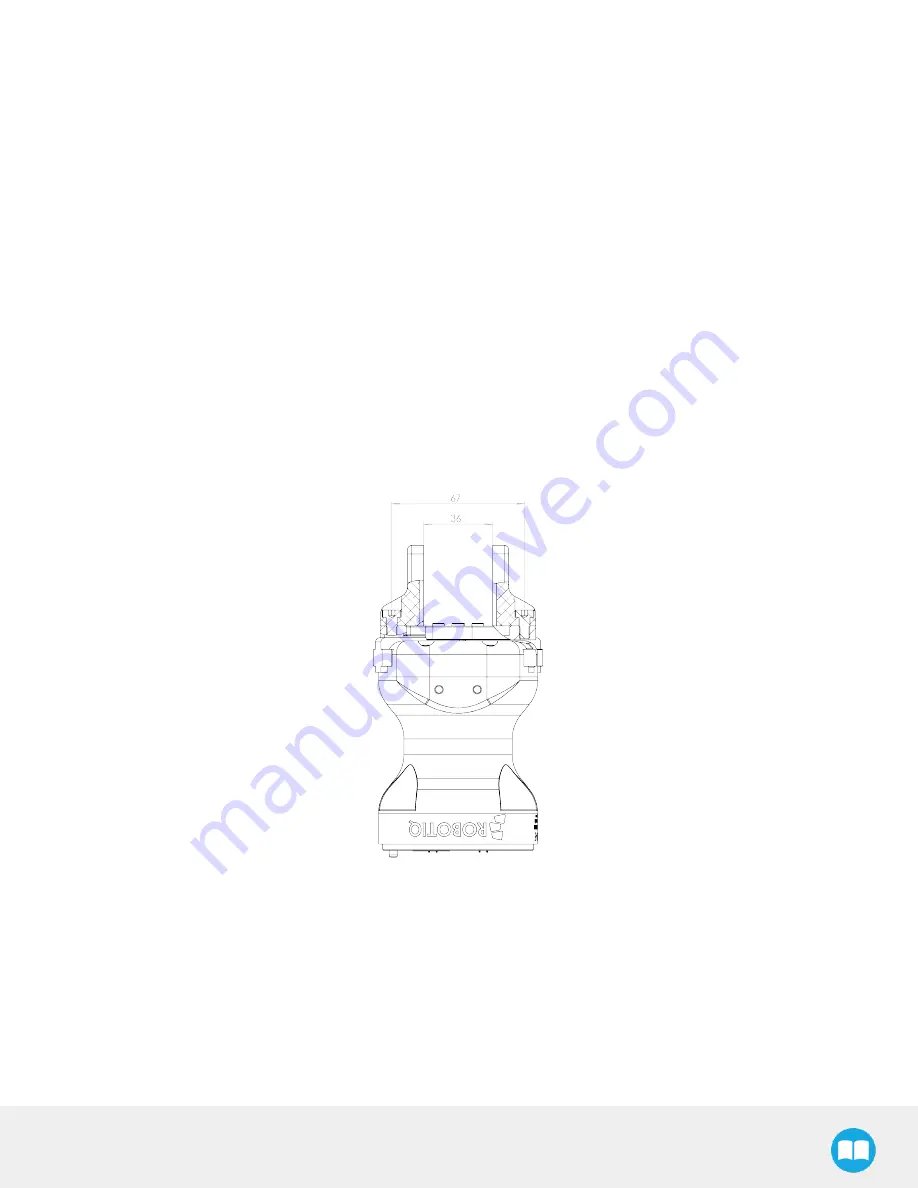

Fig. 1-5: Hand-E fully closed with Fingertips Extender and V-groove fingers.

9

Summary of Contents for CNC Machine Tending Kit

Page 2: ...Robotiq CNC Machine Tending Kit Instruction Manual 2...

Page 13: ...Robotiq CNC Machine Tending Kit Instruction Manual Fig 1 11 Wrist Camera hardware 13...

Page 139: ...Robotiq CNC Machine Tending Kit Instruction Manual 1 3 3 IngressProtection Certificate 139...

Page 141: ......

Page 143: ...Robotiq CNC Machine Tending Kit Instruction Manual 1 5 2 IngressProtection Certificate 143...