The following sequence is only applicable when the SlimZone Classic system is used in

heat pump applications and the system is in the HEAT ONLY or AUTO mode of operation.

The auxiliary heat in heat pump systems is controlled by an internal control panel timer.

Whenever the heat pump is in the heating mode, the control panel will energize the auxiliary

heat output if the heating call is not satisfied within 15 minutes. Once the auxiliary heat is

energized, it will remain on until the heating call is satisfied.

When the control panel is used with an add-on heat pump, it will ensure that the

compressor is de-energized whenever the auxiliary heat is energized. This eliminates the

need for fossil fuel kits. In the event of a heat pump compressor failure, emergency heat

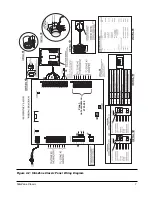

is activated through an EH switch located on the control panel (Figure 4.2, Table 6.2).

When the switch is placed in the EH position, the Y1 terminal output to the compressor will

always be de-energized and the W1 terminal will automatically replace the function of Y1.

The upstaging sequence will be canceled and any call for heating will energize W1.

6.

CONTROL PANEL SETUP

For heat/cool systems (gas, oil or electric), the control panel slide switches have the

following functions:

Switch #

Position

Description

1

OFF (down)

establishes that the system is in the HEAT/COOL mode of operation

2

OFF (down)

fan controlled by plenum thermostat

ON (up)

fan ON immediately with heat calls (for electric furnaces)

3

N/A

switch has no function in HEAT/COOL application; leave OFF

Table 6.1: Switch functions in heat/cool systems

For heat pump applications the control panel slide switches have the following functions:

Switch #

Position

Description

1

ON (up)

establishes the system is in the HEAT PUMP mode of operation

2

OFF (down)

standard heat pump system

ON (up)

ADD-ON system

3

OFF (down)

normal operation

ON (up)

Emergency Heat operation (EH)

Table 6.2: Switch functions in heat pump systems

SlimZone Classic

10