ROBERTS GORDON

®

CTH2-Series S

UBMITTAL

S

HEET

© 2004 Roberts-Gordon

APPLICATIONS, ENGINEERING AND DETAILED GUIDANCE ON SYSTEMS DESIGN, INSTALLATION AND PRODUCT PERFORMANCE IS AVAILABLE UPON REQUEST. ROBERTS GORDON

®

PRODUCTS ARE TO BE

INSTALLED ONLY IN ACCORDANCE WITH LOCAL LAWS, CODES AND REGULATIONS, AND ONLY BY A CONTRACTOR QUALIFIED IN THE INSTALLATION AND SERVICE OF GAS-FIRED HEATING EQUIPMENT.

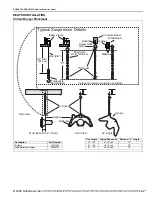

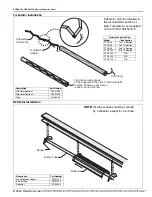

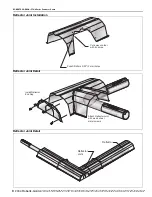

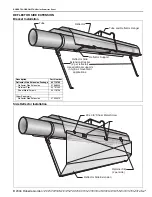

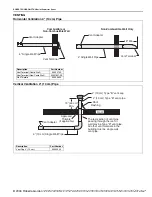

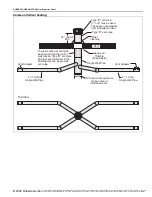

Reflector, U-Clip and Reflector Support Installation

The pictorial drawings of the heater construction in

Section

are schematic only and provide a general

guideline of where hangers, reflector supports and

U-clips are to be installed.

To ensure proper expansion and contraction move-

ment of the reflectors, a combination of U-clips and

reflector supports are used. The positioning of reflec-

tor supports and U-clips depend on the individual

installation. The following rules must be observed.

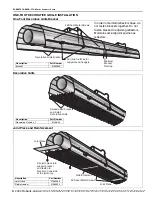

2. The overlap at the first and second reflector is a slip overlap.

Thereafter, every third reflector joint is a slip overlap. A slip

overlap is achieved by either:

a.) both reflectors lay inside a hanger.

(no reflector support needed).

b.) using a reflector support with

loose screws at the reflector

overlap.

3. The remaining reflector overlaps require a non-slip

overlap connection. To affix the reflectors together in

a non-slip overlap either:

a.) use reflector support and tight screws.

b.) if both reflectors lay inside a hanger, u-clips or

sheet metal screws may be used.

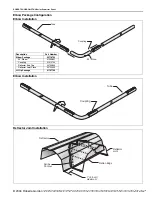

This section of three reflectors joined together must

be affixed to the tube with at least one reflector support

with tight screws.

Reflector

End Cap

U-Clips

1. The first reflector after the burner must be affixed in

the middle of the reflector with a reflector support and

tight screws.

First Reflector

6"

(16 cm)

Overlap must be a

minimum of 6" (16 cm)

Loose screws

loosened 1/16"

(2 mm) to allow

slippage.

Option A

Slip Overlap

Reflector

Support

Option B

Slip Overlap

Reflector

Tight

screws

Option B

Non-Slip Overlap

U-Clip

(2 clips per

non-slip overlap

inside a hanger)

Reflector

Option A

Non-Slip Overlap

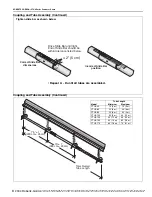

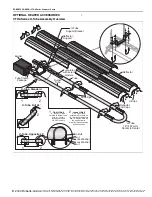

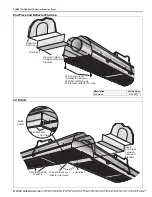

Wire Form

Reflector Support

Strap

Tight

Sheet Metal

Screw

Description

Part Number

Reflector Support Package

03050010

Wire Form

91908004

Reflector Support Strap

03050000

Screw #8 x 3/4

94320812

U-Clip Package

91107720

Reflector End Cap

027508XX