IMS01N12-E2

4

4. COMMUNICATION SETTING

Set communication setting before mounting and wiring of SRX.

Do not separate the module mainframe from the terminal

base with the power turned on. If so, instrument failure

may result.

Setting at using PLC communication

Address setting switch 1 (front) [Refer to P. 4]

Set an address of module.

Address setting switch 2 (left side) [Refer to P. 4]

Set the unit address for PLC communication.

PLC communication setting switch (left side) [Refer to P. 5]

Set the communication speed, data bit configuration, and protocol

for PLC communication. Set the same value as communication

settings of PLC.

In addition, select the communication port of modular connector.

Host communication setting switch 1 (right side) [Refer to P. 6]

Set the communication speed, data bit configuration, and protocol

for host communication using

host communication terminals

. Set

the same value as communication settings of host computer.

Setting at using host communication 1

Address setting switch 1 (front) [Refer to P. 4]

Set an address of module.

Address setting switch 2 (left side) [Refer to P. 4]

Set the unit address for host communication 1.

PLC communication setting switch (left side) [Refer to P. 5]

S

elect the communication port of modular connector.

Host communication setting switch 2 (left side) [Refer to P. 5]

Set the communication speed, data bit configuration, and protocol

for host communication 1. Set the same value as communication

settings of host computer.

Host communication setting switch 1 (right side) [Refer to P. 6]

Set the communication speed, data bit configuration, and protocol

for host communication using

host communication terminals

. Set

the same value as communication settings of host computer.

Setting at using host communication 2

Address setting switch 1 (front) [Refer to P. 4]

Set an address of module.

Address setting switch 2 (left side) [Refer to P. 4]

Set the unit address for host communication 2.

PLC communication setting switch (left side) [Refer to P. 5]

Set the communication speed, data bit configuration, and protocol

for host communication 2. Set the same value as communication

settings of host computer.

In addition, select the communication port of modular connector.

Host communication setting switch 1 (right side) [Refer to P. 6]

Set the communication speed, data bit configuration, and protocol

for host communication using

host communication terminals

. Set

the same value as communication settings of host computer.

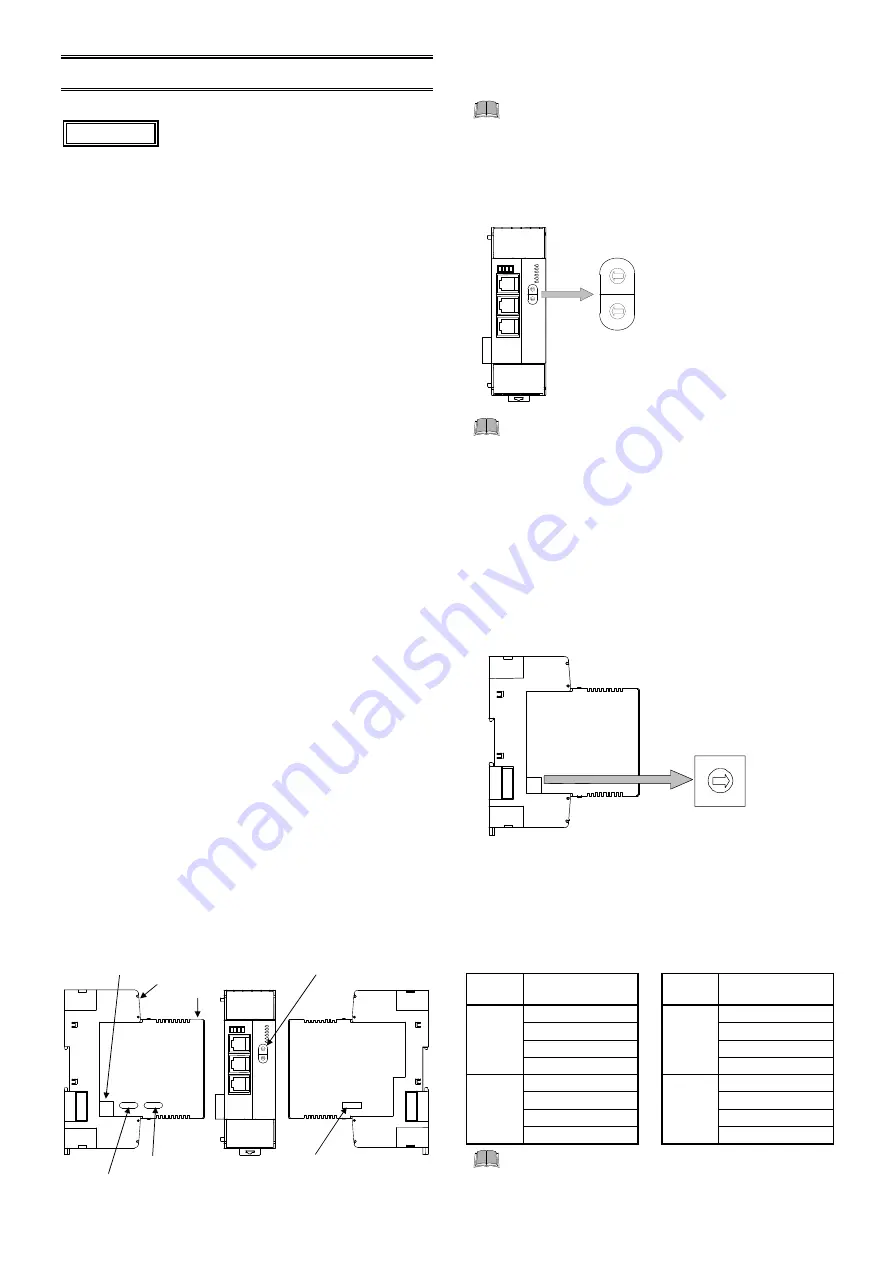

Host communication

setting switch 1

PLC communication setting switch

Host communication setting switch 2

Address setting switch 2

Address setting switch 1

Left side view

Right side view

Front view

Module mainframe

Terminal base

FAIL/RUN

RX/TX

EVENT1

EVENT2

EVENT3

EVENT4

5

4

3

2

1

0

9 8 7

6

5

5

4

3

2

1

0

9 8 7

6

5

4.1 Address Setting

Set an address. For this setting, use a small slotted screwdriver.

To avoid problems or malfunction, do not duplicate

an address on the same communication line.

Module address setting

When using two or more modules, set the desired address to

each module.

(Common to PLC communication and host communication)

High-order digit setting

(set value

10)

Setting range: 0 to 95

(Factory set value: 0)

Low-order digit setting

(set value

1)

Address setting switch 1 (for module address)

FAIL/RUN

RX/TX

EVENT1

EVENT2

EVENT3

EVENT4

5

4

3

2

1

0

9 8 7

6

5

5

4

3

2

1

0

9 8 7

6

5

5

4

3

2

1

0

9 8 7

6

5

5

4

3

2

1

0

9 8 7

6

5

Do not set address 96 to 99.

Otherwise, malfunction may result.

For Modbus, the value obtained by adding “1” to

the set address corresponds to the address used

for the actual program.

Set the module address such that it is different to

the other addresses on the same line. Otherwise,

problems or malfunction may result.

Unit address setting

When two or more X-TIO-R modules are multi-drop connected,

set an address to each X-TIO-R module. This becomes the unit

address of the SRX unit.

(Common to PLC communication/host communication)

Left side view

Setting range:

0 to 15 [0 to F: hexadecimal]

(Factory set value: 0)

9

8

7

C

B

A

6

5

4

3

2

1

0

F

E

D

Address setting switch 2

(for unit address)

PLC communication

Up to four X-TIO-R modules can be connected to a PLC

communication port. Therefore the unit address uses the four

X-TIO-R modules as a group. Use consecutive numbers in any

one of four groups in the following table as unit address.

Group

Address setting

switch 2

Group

Address setting

switch 2

Group 1

0

Group

3

8

1

9

2

A

3

B

Group 2

4

Group

4

C

5

D

6

E

7

F

Always set the unit address of each group including

0, 4, 8 or C. 0, 4, 8 or C becomes the master for

communication transfer.

CAUTION