3 Device description

Rittal cooling unit assembly and operating instructions

5

EN

3

Device description

Depending on the model chosen, your cooling unit

may vary in appearance from the illustrations con-

tained in these instructions. However, the functions

are identical in principle.

Fig. 1:

Unit description

Legend

1

Enclosure

2

Air outlet holes

3

Rating plate

4

Louvred grille for air inlet

5

Display

6

X2 master-slave connection (underside of the unit)

7

X1 terminal strip (underside of the unit)

8

X3 optional serial interface (underside of the unit)

9

Dispatch bag

10

Twin-threaded bolt

11

Condenser

12

Condensate discharge

3.1 Functional description

Enclosure cooling units are designed to dissipate

heat from enclosures by cooling the air inside the

enclosure and so protect the temperature-sensitive

components. It is mounted on the roof of an enclo-

sure.

3.1.1 How it works

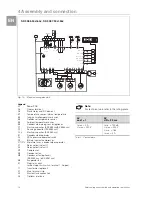

The cooling unit (compression refrigeration system)

is comprised of four main components (cf. Fig. 2):

the evaporator (1), the coolant compressor (2), the

condenser (3), and the control or expansion valve

(4), which are connected by suitable pipework.

This circuit is filled with a readily boiling substance,

the refrigerant. Coolant R134a (CH

2

FCF

3

) is chlorine-

free. Its ozone destruction potential is 0, making it

very eco-friendly. A filter dryer (5) which is integrated

into the hermetically sealed cooling circuit provides

effective protection against moisture, acid, dirt parti-

cles, and foreign bodies within the cooling circuit.

Fig. 2:

Cooling circuit

In the evaporator coil (1), the liquid coolant is con-

verted to a gaseous state. The energy needed for

this purpose is taken from the enclosure air in the

form of heat, which has the effect of cooling the

enclosure air. In the compressor (2), the coolant is

heavily compressed, so that it achieves a higher

temperature inside the condenser (3) than the ambi-

ent air. This means that excess heat may be emitted

to the ambient air via the surface of the condenser,

as a result of which the temperature of the coolant

drops and it is converted back into liquid. It is

re-injected into the evaporator coil via a thermostatic

expansion valve (4), which causes it to cool down

further, and is then once again able to absorb the

energy from the enclosure air in the evaporator coil.

The whole cycle begins again.

3.1.2 Controller

Rittal enclosure cooling units are fitted with a con-

troller for setting the functions of the cooling unit

(display plus extended functions, see chapter

“6 Operation”, page 16).

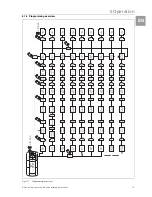

3.1.3 Bus mode (e-Comfort controller only)

The serial unit interface X2 allows you to create a bus

connection with up to ten cooling units using the

master-slave cable (shielded, four-wire cable, Model

No. SK 3124.100). This allows you to implement the

following functions:

– Parallel unit control (the cooling units in the network

can be switched on and off simultaneously)

– Parallel door status message (“door open”)

– Parallel collective fault message

3

6, 7, 8

12

4

11

10

9

5

2

1

PSA

H

pressure-

operated

switch

Condenser fan

Expansion valve (4)

Temperature

control

Filter dryer (5)

Internal circuit

Compressor

(2)

External circuit

Evaporator fan

Evaporator coil (1)

Condenser (3)

Summary of Contents for SK 3273.xxx

Page 2: ......