5 Commencing operation and control behavior

Rittal cooling unit assembly and operating instructions page

5

of

13

press the SET button to access the password

setting; use the UP and DOWN buttons to scroll

the numbers until displaying “22” (password to

access the parameters);

press the SET button to confirm the password ;

use the UP and DOWN buttons to scroll the pa-

rameters. The LED corresponding to the catego-

ry of parameters will be on (see Below Table);

press SET to display the value associated with

the parameter increase or decrease the value us-

ing the UP or DOWN button respectively;

press SET to temporarily save the new value and

display the parameter again;

repeat the procedure for any other parameters

that need to be modified;

press the SET button for more than 3 s to per-

manently save the parameters and exit the pa-

rameter setting procedure.

Accessing the type S parameters:

press SET for 1 s, the set value will start flashing;

increase or decrease the value using UP or

DOWN;

press SET to confirm the new value.

5.1.4

Setting the target temperature

The temperature is preset at the factory to 35

℃

.

press SET for 1 s, the set value will start flashing;

increase or decrease the value using UP or

DOWN;

press SET to confirm the new value.

5.1.5

Setting the temperature range

Press the SET button for more than 3 s (if there

are active alarms, mute the buzzer), the display

shows the parameter code “PS” (password);

press the SET button to access the password

setting; use the UP and DOWN buttons to scroll

the numbers until displaying “22” (password to

access the parameters);

press the SET button to confirm the password;

use the UP and DOWN buttons to scroll the pa-

rameters.

press SET to display the value associated with

the parameter increase or decrease the value us-

ing the UP or DOWN button respectively;

press SET to temporarily save the new value and

display the parameter again;

repeat the procedure for any other parameters

that need to be modified;

press the SET button for more than 3 s to per-

manently save the parameters and exit the pa-

rameter setting procedure.

Notice!

It is not allowed to change the value for

„r1 & r2“ without Rittal authorization

5.1.6

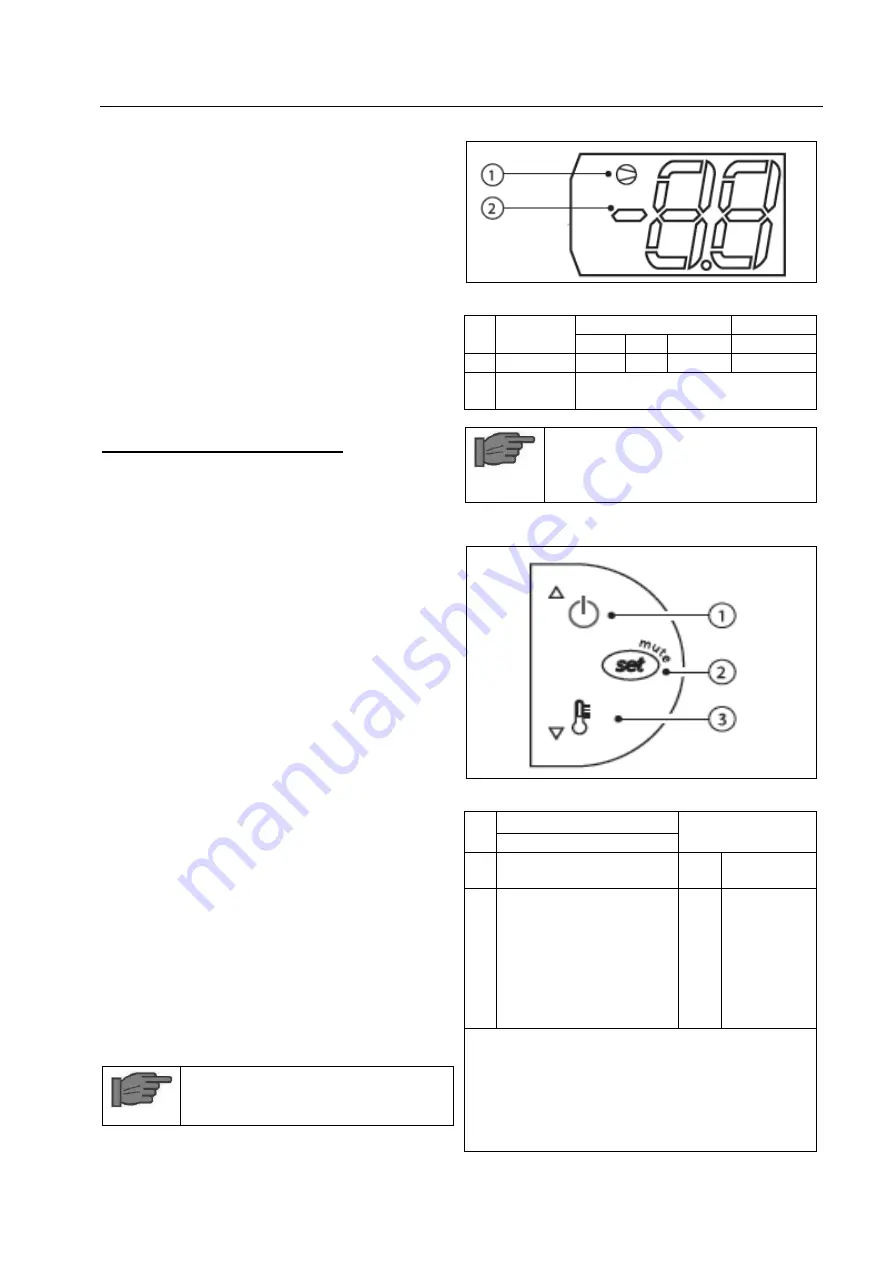

Controller display

Figure 2: Controller display

function

Normal operation

Start up

no.

on

off

flash

1

compressor on

off

call

on

2

digits

two digits with sign and decimal

point, -99 to 99(*).

Notice!

The parameters that feature three digit

values can be set from the supervisor.

In this case the display will show “---“

5.1.7

Display buttons

Figure 3: Display buttons

no.

Normal operation

Start up/ reset

Pressing the button alone

1

more than 3 s: switch the

compressor ON/OFF

-

2

1 sec: displays/sets

the set point

more than 3 sec.: ac-

cesses the parameter

setting menu (enter

password 22)

mutes the audible

alarm (buzzer)

-

pressed

together (2

and 3) acti-

vate parame-

ter reset pro-

cedure

Start up/ reset to factory setting parameters

Disconnect power supply

Reconnect power supply while holding but-

tons 2 and 3

Display will show the message “CF”

After a few seconds the unit will restart with

factory setting parameters