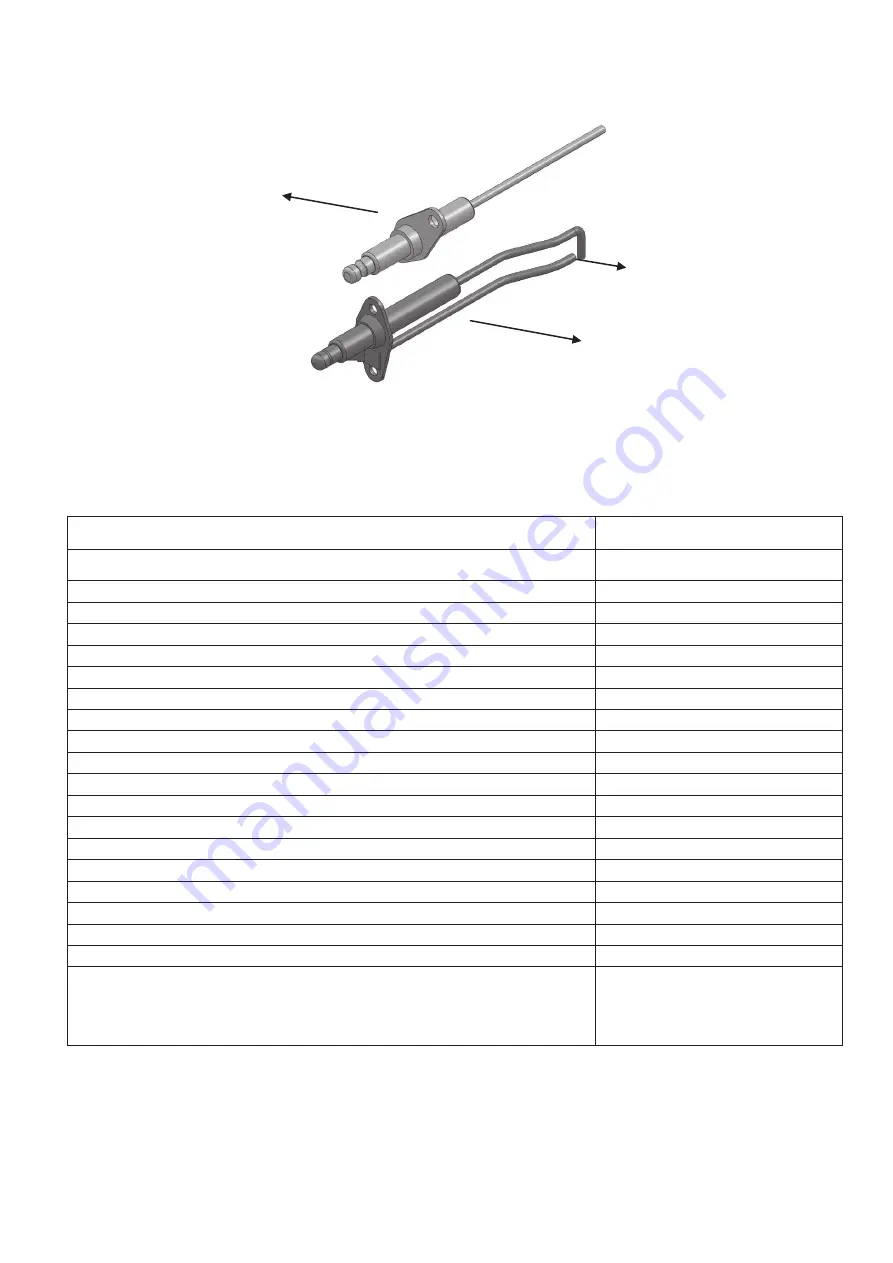

Checking the electrodes

Check the ignition electrode adjustment (between 3 and 3,5 mm) and replace electrode if necessary (including sealing). Also

check the electrode's porcelain for hairline fractures because this may cause spark-over.

Commissioning Form

Commissioning Steps

Values or Confirmations

1. Fill the central heating system with water. Check the water pressure in the central

heating system.

O

2. Fill siphon with water.

O

3. Vent central heating system

O

4. Check circulation pump operation

O

5. Check water-side connections for leakage

O

6. Check type of gas offered and Flue gas measured

CO

2

:

O

2

:

NO

x

:

7. Check the gas supply pressure

O

8. Check gas meter capacity

O

9. Check the gas leakage of the connections and the gas pipes

O

10. Vent gas supply pipe

O

11. Check electrical connections

O

12. Air supply and flue gas discharge connections checked

O

13. Check function and operational status of the boiler

O

14. Check whether the gas/air ratio control is correct

O

15. Measuring equipment removed and cap refitted on flue gas measuring point

O

16. Refit boiler front cover panels again in the proper manner(see boiler de-montage)

O

17. Mark the gas type on the boiler plate

O

18. Set room thermostat or boiler control to desired value

O

19. Instruct user and hand over the necessary documents

O

20. Confirmation of commissioning

(Company name, signature of engineer)

Date :

Ignition Electrode

Flame Sensing

Electrode

3

–

3,5 mm

Summary of Contents for ONGAS 300/W Series

Page 6: ...Operating Instructions ...

Page 7: ......

Page 8: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 28: ...Fault Finding ...

Page 29: ......

Page 30: ......