13

ADJUSTMENTS

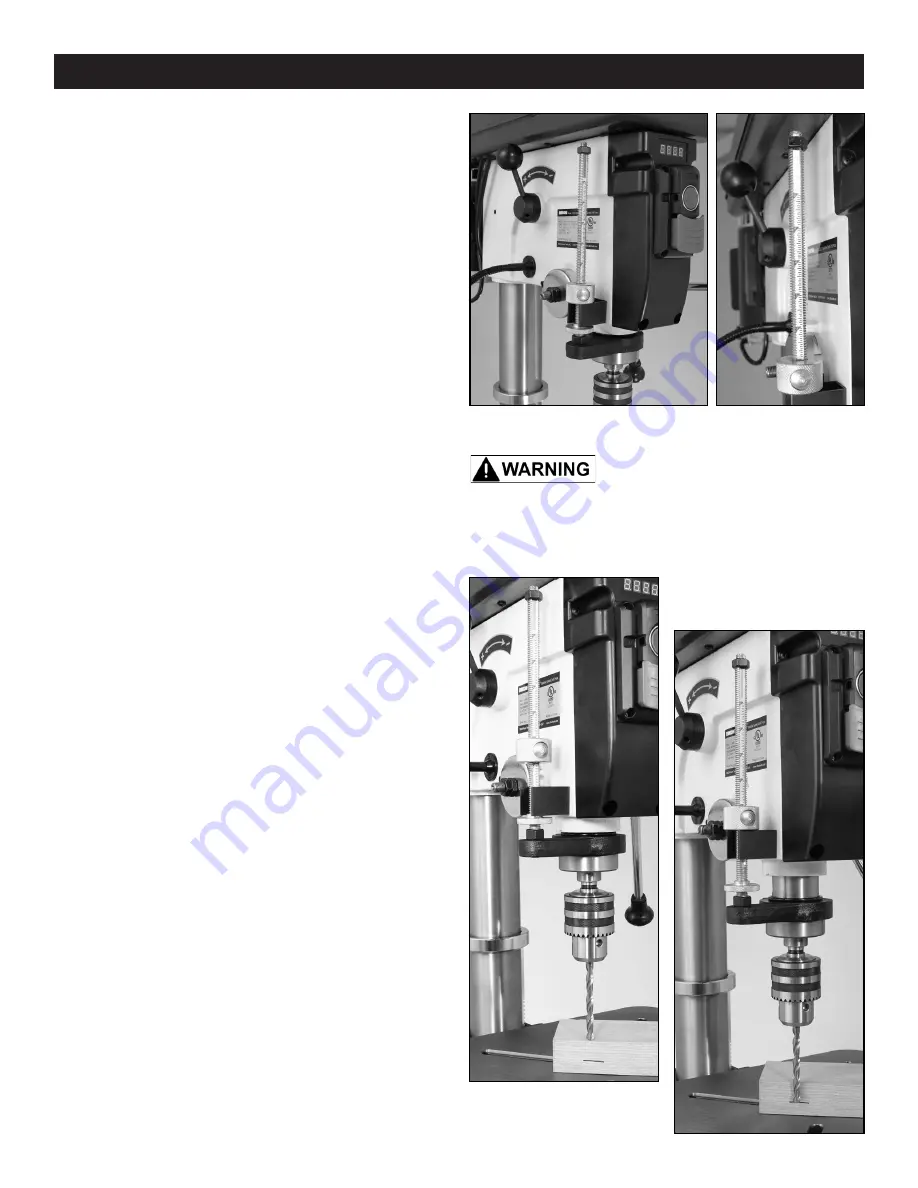

ADJUSTING THE DEPTH STOP

The Depth Stop is used for boring multiple holes at

the same, identical depth. The threaded rod includes

a scale and a large quick release nut for fast setting of

the depth that the spindle/chuck will travel. FIG. 17.

The chuck’s travel distance/depth is read on the scale

at the top of the Depth Setting Nut (#16 on Parts

Diagram D). At reading ‘0’, the Depth Setting Nut

should be down on top of the Depth Plate (#58 on

Diagram B). FIG. 17.

Setting the a specific depth can be done in 2 ways:

THE DEPTH SCALE METHOD

1. With your workpiece on the table, raise the table

until the surface of the workpiece touches the drill bit

that is in the chuck. Lock the table in position.

2. Adjust the Depth Setting Nut to the desired depth

on the threaded rod’s scale. The Depth Nut has a

quick release button for fast moving of the nut.

NOTE:

Depth is read at the TOP of the nut. The

Depth Nut can also be rotated for fine depth

adjustments. FIG. 18.

3. Drill a test hole to check the depth setting, and

adjust the depth setting as necessary. It is best to

use a scrap piece of wood, that is the exact same

thickness of your workpiece, for test drilling to ensure

the proper results.

THE WORKPIECE METHOD

1. Mark a line on the side of a workpiece at the

desired depth needed.

2. Lower the drill bit that is in the chuck along the side

of the workpiece, until it aligns with the drawn line.

NOTE:

The machine must be OFF for this procedure.

3. Holding the drill bit at the desired depth, lower

the Depth Setting Nut until it rests down on the metal

Depth Plate. The drilling depth is now set.

4. Drill a test hole to check the depth setting, and

adjust as necessary. It is best to use a scrap piece of

wood that is the exact same thickness of your work-

piece for test drilling, to ensure the proper results.

FIG. 17

FIG. 18

FIG. 19

THE MACHINE MUST NOT BE

PLUGGED IN AND THE POWER SWITCH MUST BE IN

THE OFF POSITION UNTIL ALL ADJUSTMENTS ARE

COMPLETE.