9 Troubleshooting

- 50 -

<Abnormalities of Readings>

Symptoms Causes

Actions

The reading rises (drops)

and it remains so.

Drifting of sensor

output

Perform zero adjustment.

Presence of

interference gas

Disturbances by interference gases, such as solvents,

cannot be eliminated completely.

Slow leak

A very small amount of the gas to be detected may be

leaking (slow leak). Because ignoring it may cause

dangers, take a remedial measure, i.e., taking actions the

same as those for the gas alarm.

Environmental

changes

Perform the zero adjustment (AIR adjustment).

A gas alarm is triggered

despite of no gas leak

and no other

abnormalities at the

detection point.

Presence of

interference gas

Disturbances by interference gases, such as solvents,

cannot be eliminated completely.

Disturbance by noise

Turn off and restart the detector.

If such a symptom is observed frequently,

take appropriate measures to eliminate the noise.

Sudden change in

the environment

When the environment (temperature etc.) changes

suddenly, the detector cannot adjust to it and is affected

by it.

In some cases, the detector triggers an indication alarm.

Because the detector cannot be used under sudden and

frequent environmental changes, any preventive actions

to eliminate them should be taken by the user.

Slow response

Clogged dust filter

Replace the dust filter.

Bended, clogged,

or leaked suction

tube or exhaust

tube

Fix the defective parts.

Condensation is

formed inside the

suction tube.

Fix the defective parts.

Deteriorated sensor

sensitivity

Replace the sensor with a new one.

Span adjustment

impossible

Improper calibration

gas concentration

Use the proper calibration gas.

Deteriorated sensor

sensitivity

Replace the sensor with a new one.

Summary of Contents for SD-1DEC

Page 1: ...PT2E 1789 Smart Transmitter Gas Detector Head SD 1DEC Operating Manual PT2E 178 PT2 178...

Page 6: ......

Page 7: ......

Page 8: ......

Page 9: ......

Page 10: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 34: ......

Page 35: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

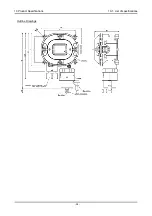

Page 56: ...10 Product Specifications 10 1 List of specifications 54 Outline Drawings...

Page 57: ......

Page 59: ......