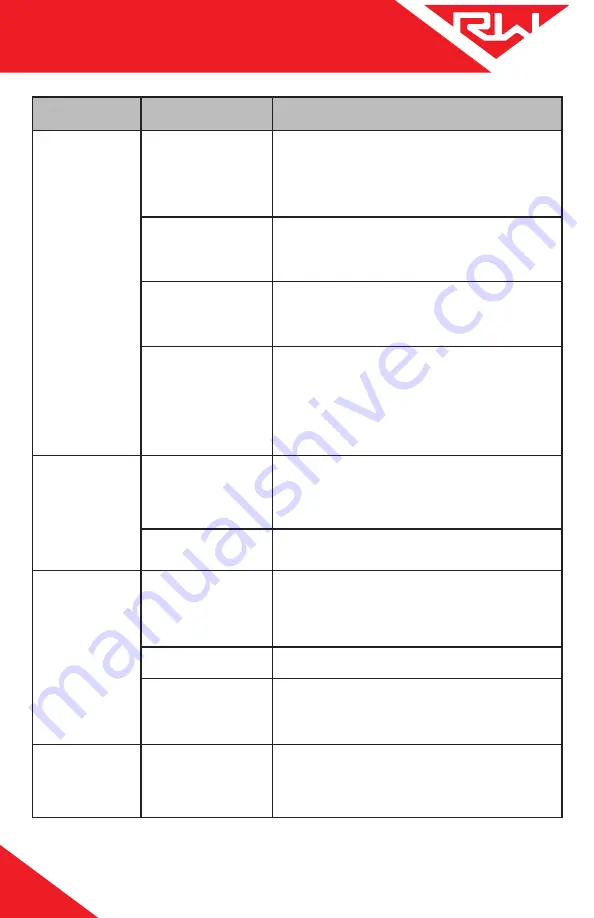

TROUBLESHOOTING

16

PROBLEM

CAUSE

SOLUTION

Erratic / Inaccurate

Weight Readings

The vehicle is not parked on

a level surface

Park on level concrete ground.

Parking on sloped or banked

surfaces will cause the vehicle weight distribution to shift

between the axle groups. Additionally,

if one or more of the

vehicle’s wheels are in a pothole, that could result in additional

pressure or torque on the suspension air bags. This will cause the

suspension to have a different air pressure than what is normally

needed to hold up the given weight.

The vehicle’s brakes are on

Release the parking brakes when weighing and/or calibrating.

When the vehicle brakes are set, they could apply additional

pressure or torque on the suspension air bags. This will cause the

suspension to have a different air pressure than what is normally

needed to hold up the given weight.

There is a significant air leak

in the suspension system

Check air lines for leaks. Having a leak could cause the HCV to

refill the suspension at regular intervals to maintain the vehicle’s

ride height. If there is a significant leak, the gauge display will

slowly decrease in value and then quickly increase in value when

the HCV refills the suspension system.

The Height Control Valve

(HCV) is malfunctioning or

broken

If the HCV is not functioning correctly, the air pressure applied to

the suspension system could be inconsistent and/or erratic. To

test for an HCV problem, acquire a weight reading from the Right

Weigh gauge and write it down (refer to gauge operating

instructions for proper procedure). Drive the vehicle around the

block and return to the same location. Acquire a second reading

from the Right Weigh gauge. If the two readings are significantly

different, then the HCV might be malfunctioning.

Gauge Will Not

Calibrate Low/High

Air pressure in the system is

not changing

To enter low or high cal mode, the gauge must see a measurable

change in air pressure. Make sure you calibrate high when the

vehicle is near the legal limit and calibrate low when the truck is

empty. Also, be sure the air line is connected directly to an air bag

- NOT the main air supply or brake system.

App Won’t Connect

to the Gauge

Scale is connected to a

constant power source

Connect the scale to a switched power source between 9 and 32

VDC (typically either the vehicle marker lights or the AUX/ABS

wire).

If the gauge is powered too long it can stop transmitting a

Bluetooth signal and may need to be disconnected and

reconnected to work again.

Scale is connected to

another device

Disconnect the scale from the other device before connecting

through your device.

Phone requires re-set

To reset your phone - close the app, turn off Bluetooth, and wait

10 seconds. Then open the app and turn the Bluetooth back on.

Try rescanning for the scale. If this still doesn’t work, in some

cases it is necessary to restart the phone completely.

Gauge reading “noAir”

One or more air inputs are

not receiving air (If 2 air

sensors are set to Average

mode and one isn’t

receiving air, gauge will read

noAir message)

Check that all air inputs are receiving air. Pull airline out of air

fitting(s) on the back of the gauge. Follow the airline along the

vehicle to the airbags to check that it hasn’t been pinched or

damaged. Dump suspension and refill to ensure air bags are full.

Lift Axle being measured is

in the up position

If an air input is measuring a lift axle on the vehicle and the lift

axle is in the up position, the air bags will be deflated of air and

the gauge will read the noAir message.

Summary of Contents for 201-EBT-04B

Page 21: ...NOTES 21 ...

Page 22: ...NOTES 22 ...